Novel deodorization drain pipe for kitchen sink

A washing basin and drainage pipe technology, which is applied in the field of new washing basin deodorizing drainage pipes, can solve the problems of reducing space utilization, increasing use cost, and weak connection, and achieves the advantages of easy installation and debugging, low production cost, and improved applicable environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

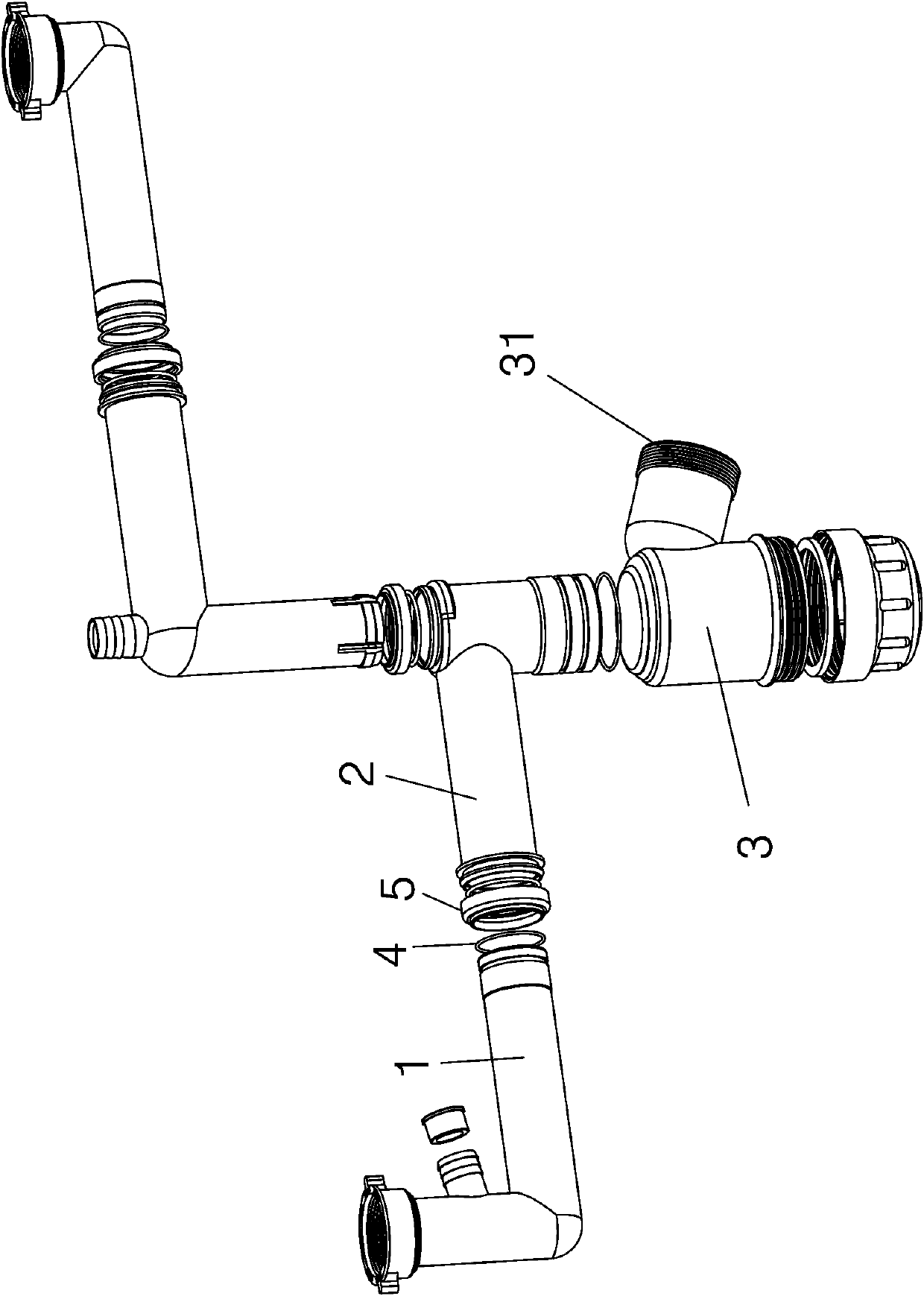

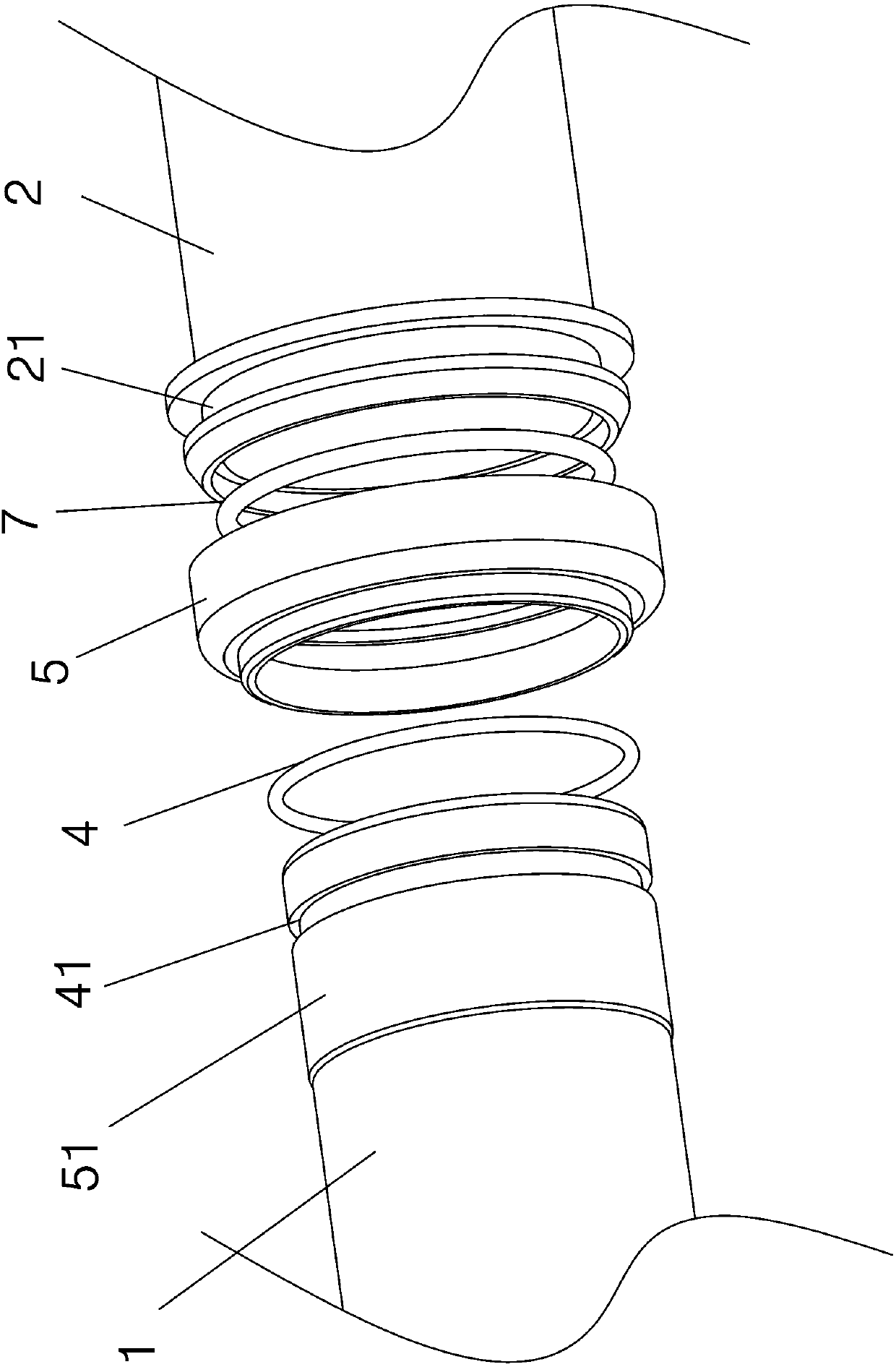

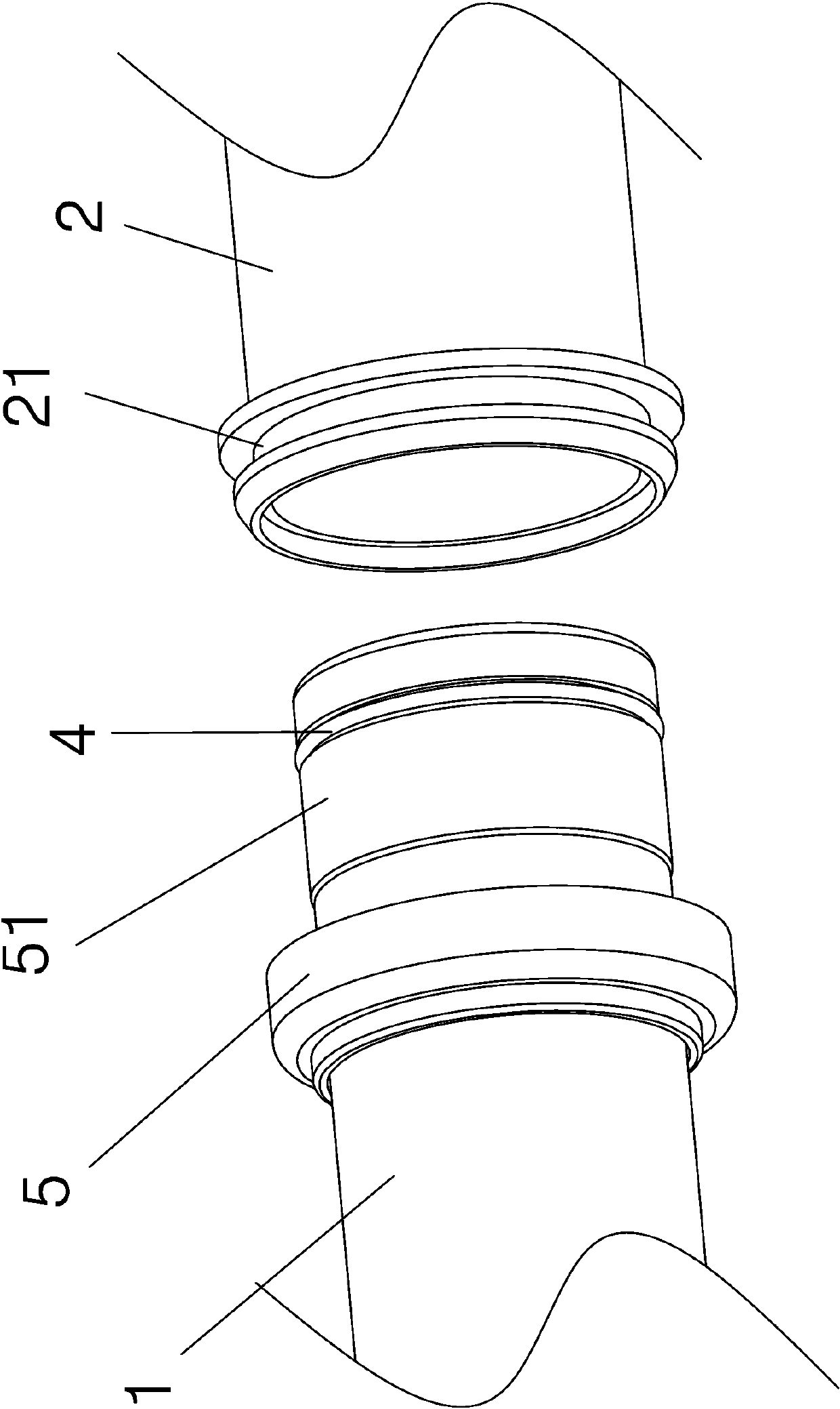

[0017] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A new type of anti-odor drainage pipe for washing basin, which includes a water receiving pipe connected to the drain of the washing basin, the water receiving pipe 1 is connected to the deodorant pipe 3 through the transfer pipe 2, and the deodorant pipe 3 is provided with an overflow port 31 to be connected to the sewer, and is characterized in that: The first sealing ring 4 is installed on the water receiving pipe 1 and then inserted into the transfer pipe 2 to dock with it. The surface of the water receiving pipe 1 is also provided with a limit ring 5 and a limit boss 51, and the limit ring 5 is buckled on the end surface of the transfer pipe. fixed.

[0018] The limiting boss 51 is provided with a mounting groove 41 for mounting the first sealing ring 4 .

[0019] The position-limiting ring 5 is provided with a positioning boss 52 , and the positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com