Construction method of concrete framework structure with beam end constraining and releasing functions

A construction method and frame structure technology, applied in the direction of building structures, buildings, building components, etc., can solve the problems of large bearing capacity, large effective area of bending resistance, large rigidity, etc., and achieve the effect of releasing constraints and improving the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

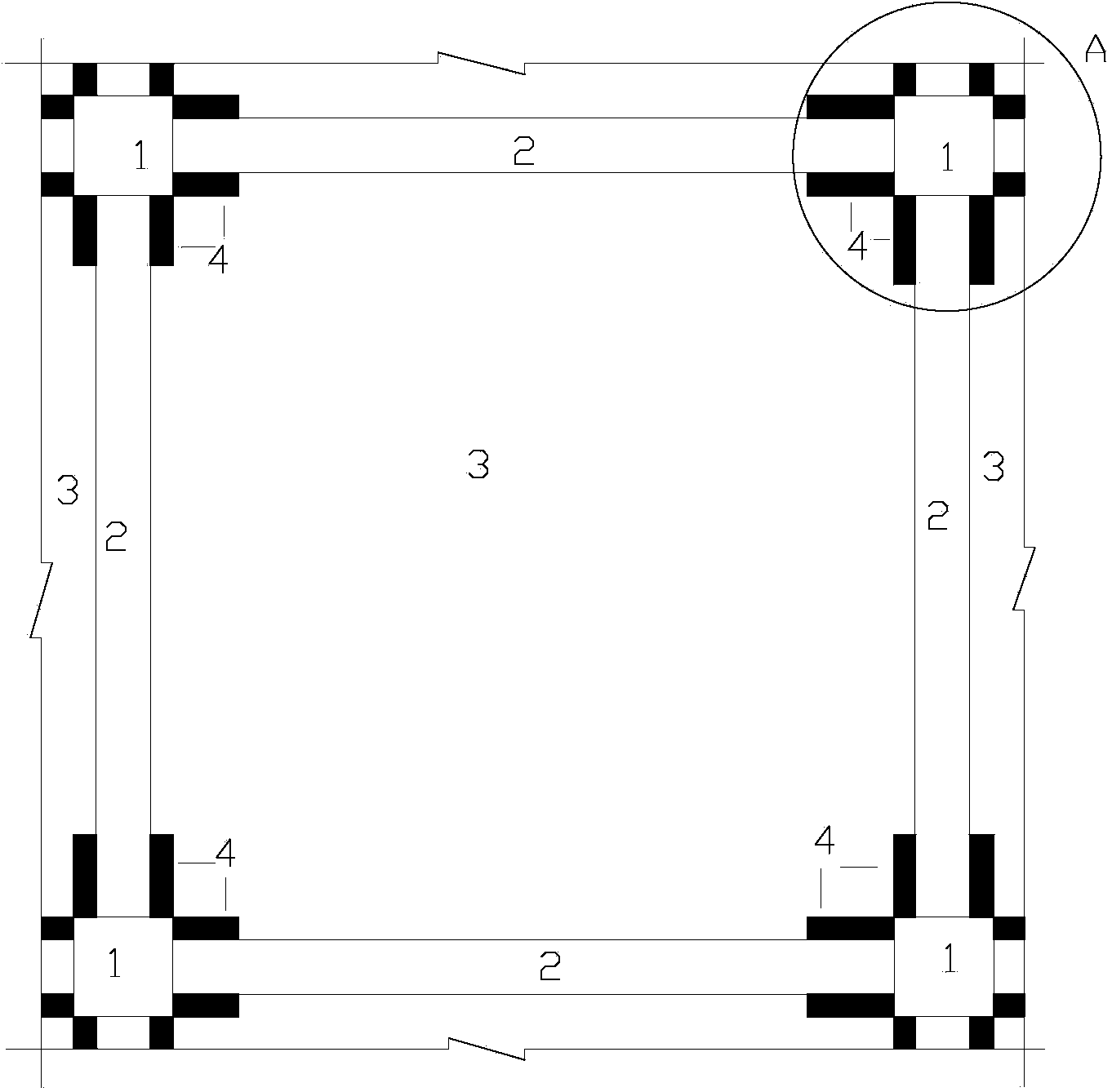

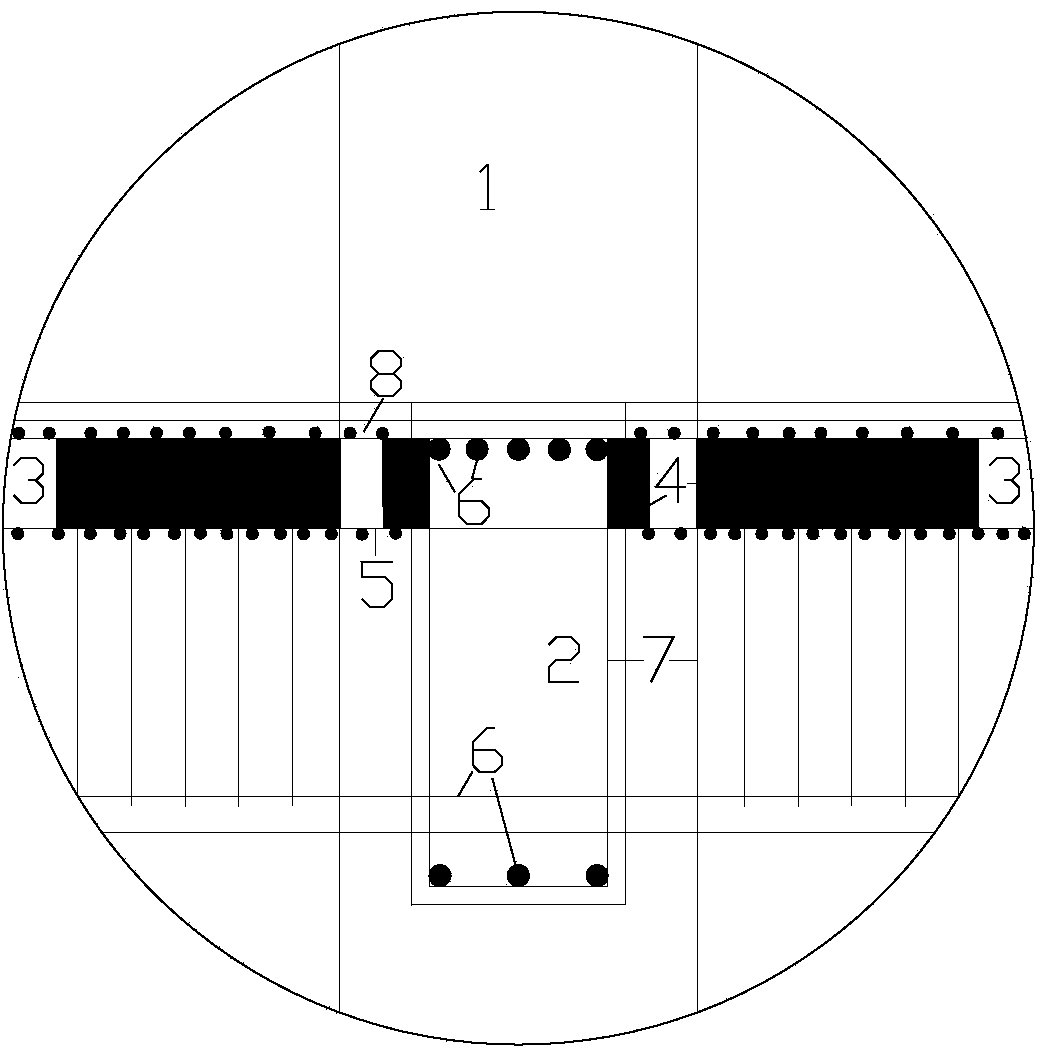

[0033] refer to figure 1 and figure 2 , a method for constructing a concrete frame structure with a beam end restraint release function, comprising the following steps:

[0034] 1) Position the floor column, arrange the column reinforcement, and form the formwork to the bottom of the beam

[0035] First, establish the position of column 1 and the position of the formwork. For the lengthening of shorter column longitudinal reinforcement, lap joint or welding can be used. If conditions permit, welding should be adopted as much as possible. Encryption, column formwork and formwork support and column reinforcement layout are carried out alternately from the vertical formwork to the bottom of the beam, and the column reinforcement layout passes through the upper floor. Pay attention to the densification of the stirrups at the upper end of the column and at the joints of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com