Separation characteristic test device of separation and stripping electric connector

An electrical connector and testing device technology, applied in the field of measurement and testing, can solve the problem of lack of testing equipment, and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

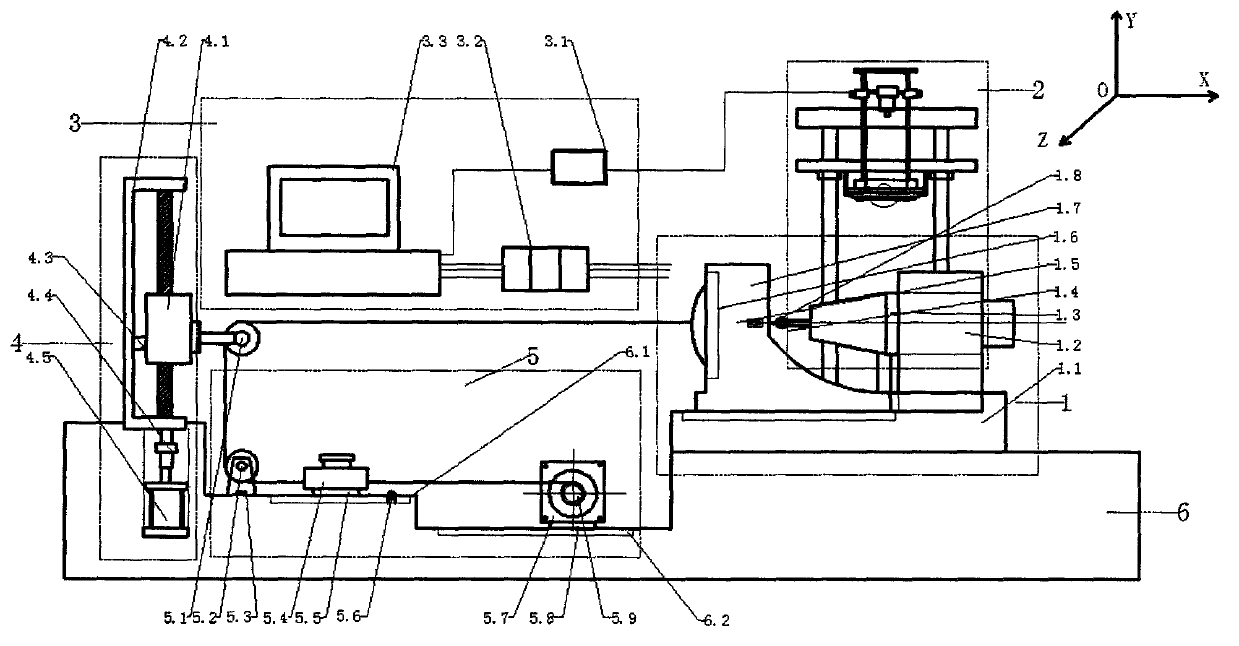

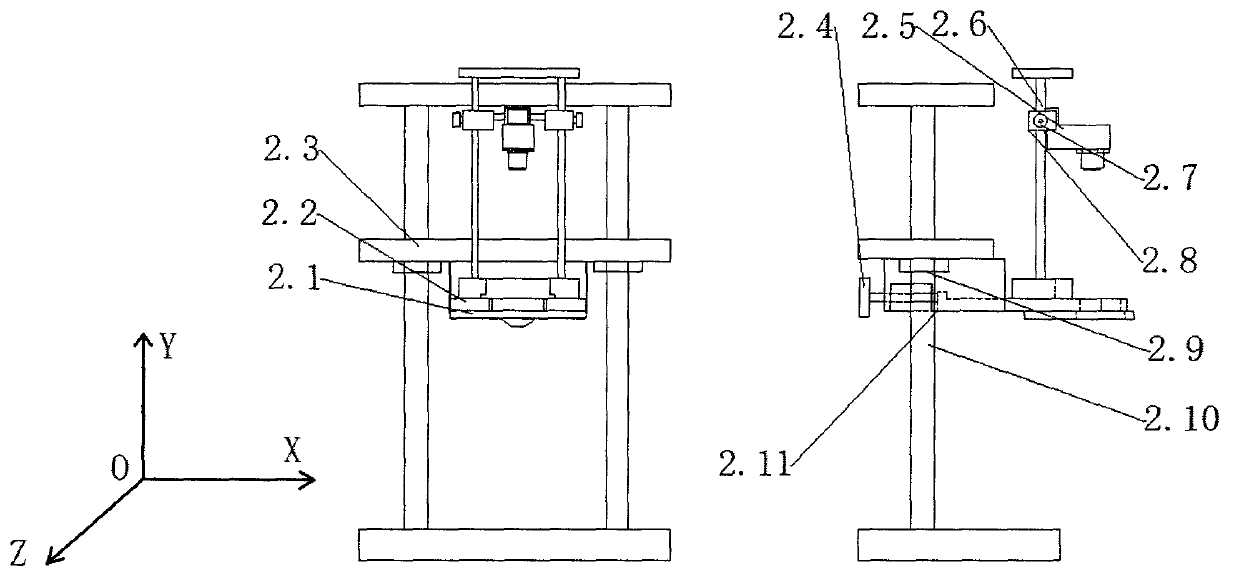

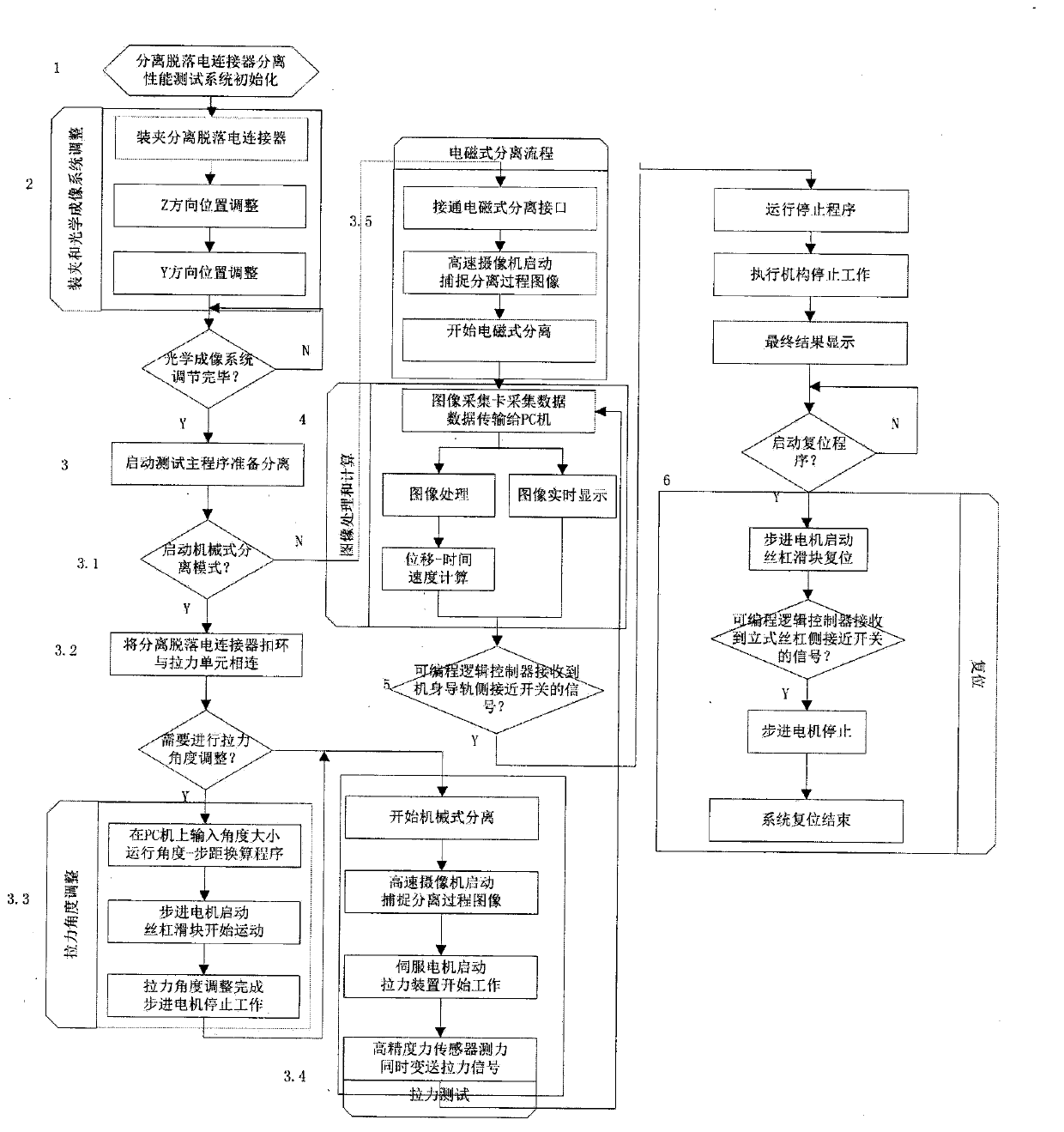

[0025] Such as figure 1 As shown, the test system designed in the present invention includes a tooling table, a high-speed camera unit, a control and data processing unit, a tension angle adjustment unit, a high-precision tension test unit and a fuselage.

[0026] Tooling table 1: the column 1.2 is installed on the workbench 1.1, the detached electrical connector 1.3 is installed on the column 1.2 with a U-shaped groove, the elastic cover 1.5 is installed at the front end of the column 1.2, and the middle part of the elastic cover 1.5 has a wire slot 1.6, The inner wall buckle 1.7 is installed on the inner side of the elastic baffle cover 1.5.

[0027] Control and data processing unit 3: including image acquisition card 3.1, programmable logic controller 3.2, PC 3.3, programmable logic controller 3.2 selects the separation mode, adjusts the tension ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com