Manufacturing technology and device for high-voltage high-power adjustable simulative transformer substation

A manufacturing technology, high-voltage technology, applied in the direction of measuring devices, measuring electrical variables, components of electrical measuring instruments, etc., can solve problems such as large power loss, damage to power lines, unrealizable current and voltage values, etc., to achieve reliable Increased performance, intelligent adjustment, and low power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

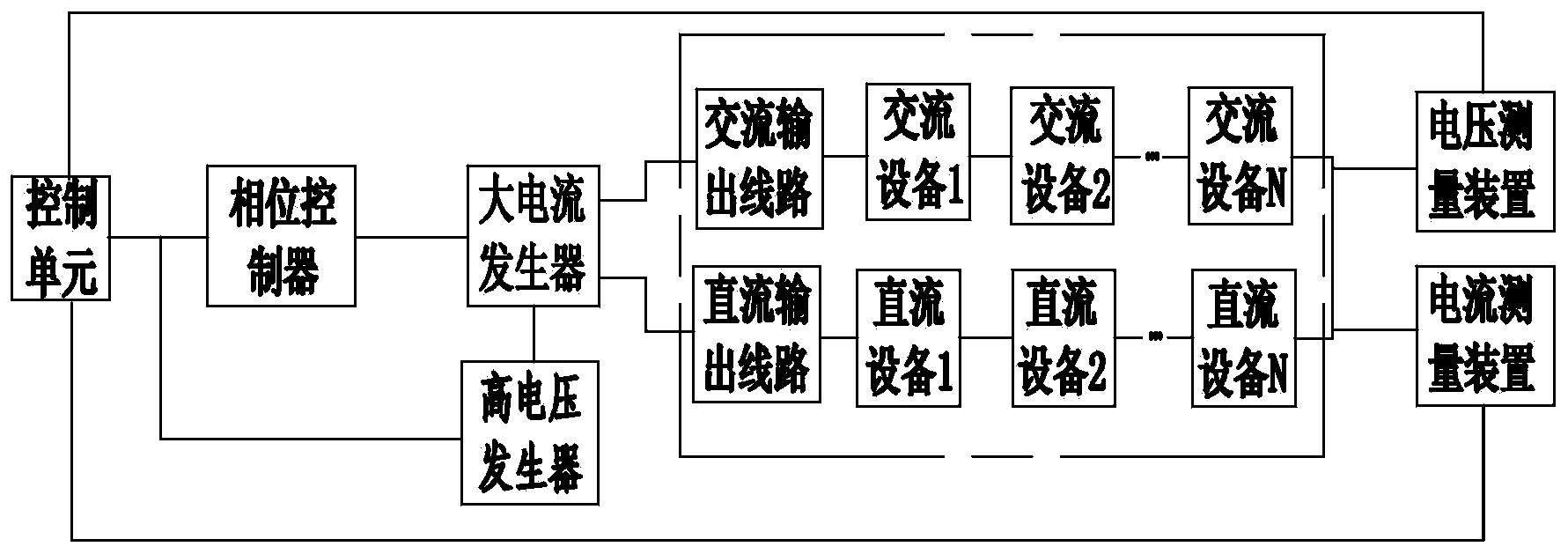

Embodiment 1

[0025] The manufacturing technology of the high-voltage and high-power adjustable analog substation described in the present invention generates a large current and a high voltage respectively through a high-current generator and a high-voltage generator. On the high current side of the high current generator, create a high current and high voltage test environment on the high current side of the high current generator, connect the phase controller to the input side of the high current generator and / or the input side of the high voltage generator, and control the The current and voltage are in the same phase. The high current side of the high current generator is connected to two parallel output lines, which are the AC output line and the DC output line. The electrical equipment under test for connecting AC power, the DC output line includes switches, AC-DC conversion devices, DC insulators and DC busbars arranged in sequence, the electrical equipment under test for DC busbar c...

Embodiment 2

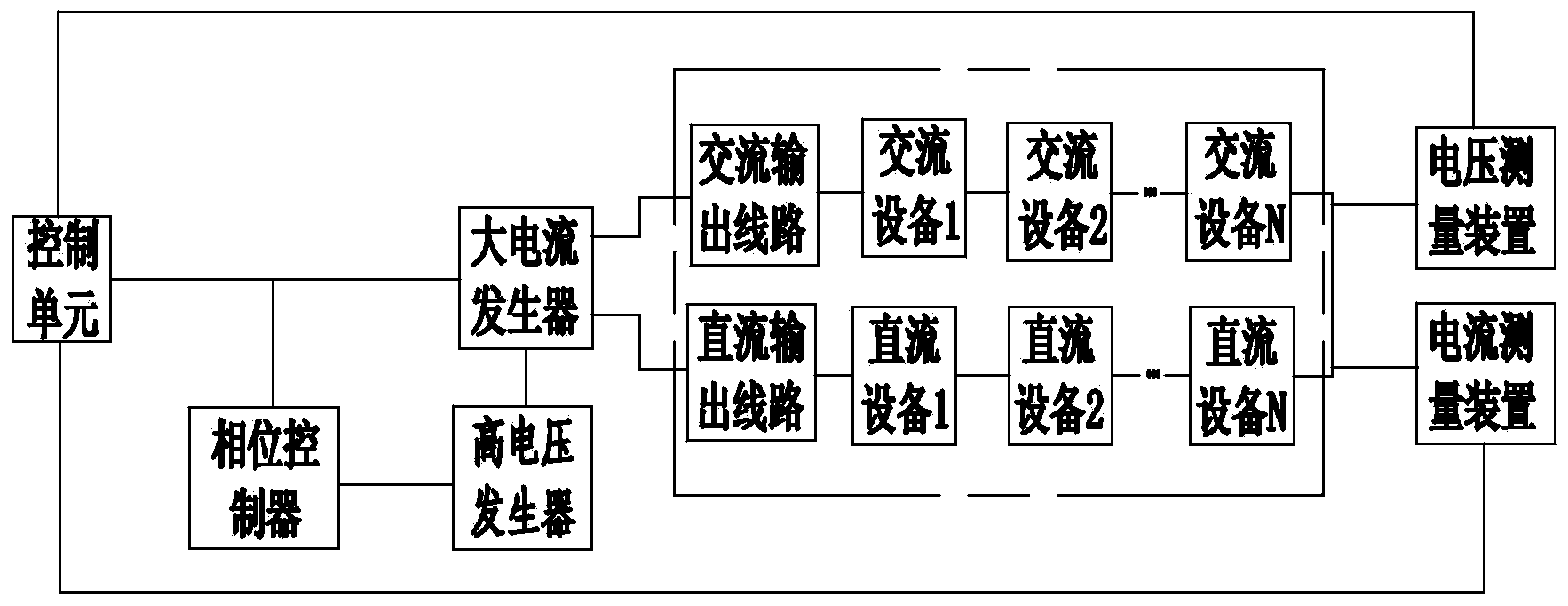

[0030] The difference between this embodiment and Embodiment 1 is that the position of the phase controller in Embodiment 1 is changed, and it is set on the input side of the high voltage generator to realize the same phase control of current and voltage. Other structures of this embodiment are the same as Example 1 is the same.

Embodiment 3

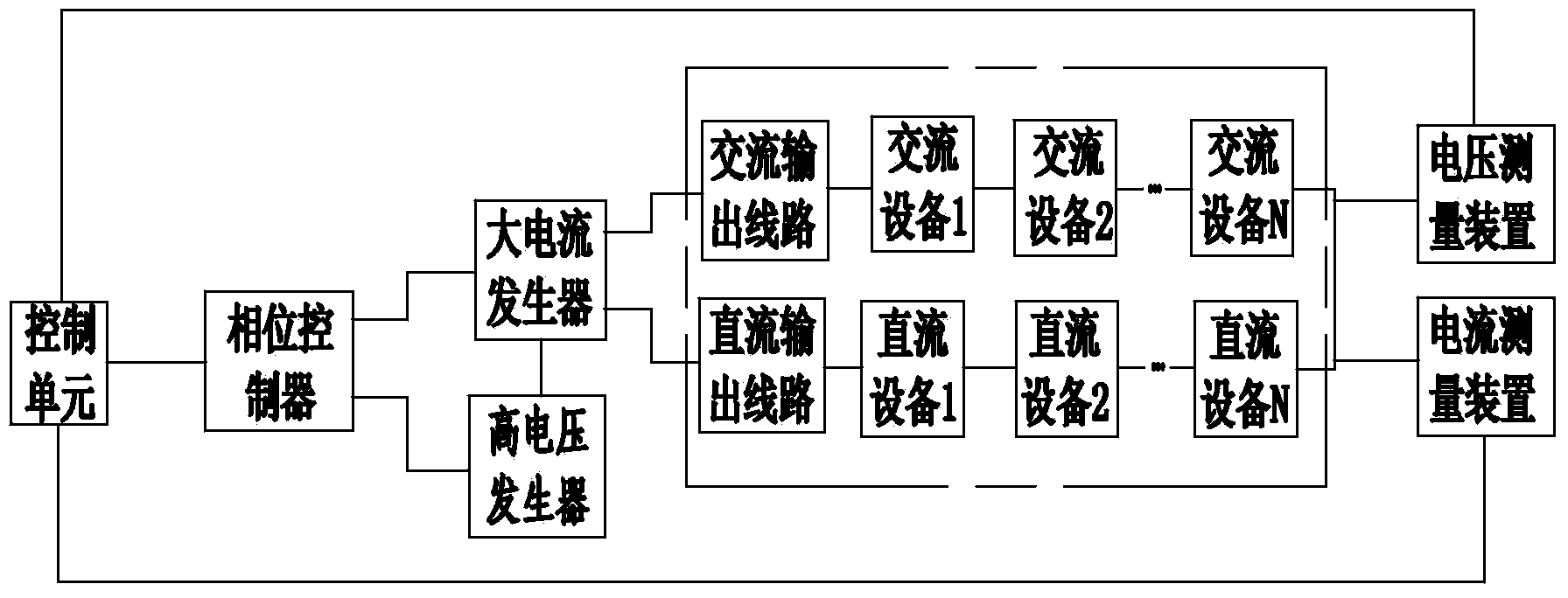

[0032] In this embodiment, on the basis of embodiment 1, a phase controller is also connected to the input side of the high voltage generator to realize the same phase control of current and voltage. Other structures of this embodiment are the same as those of embodiment 1, and other structures of this embodiment are the same as Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com