Large-aperture polarization independent high-power isolator

A high-power, large-aperture technology, applied in the laser field, can solve problems such as insufficient isolation and unstable laser quality, and achieve the effect of improving isolation and avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

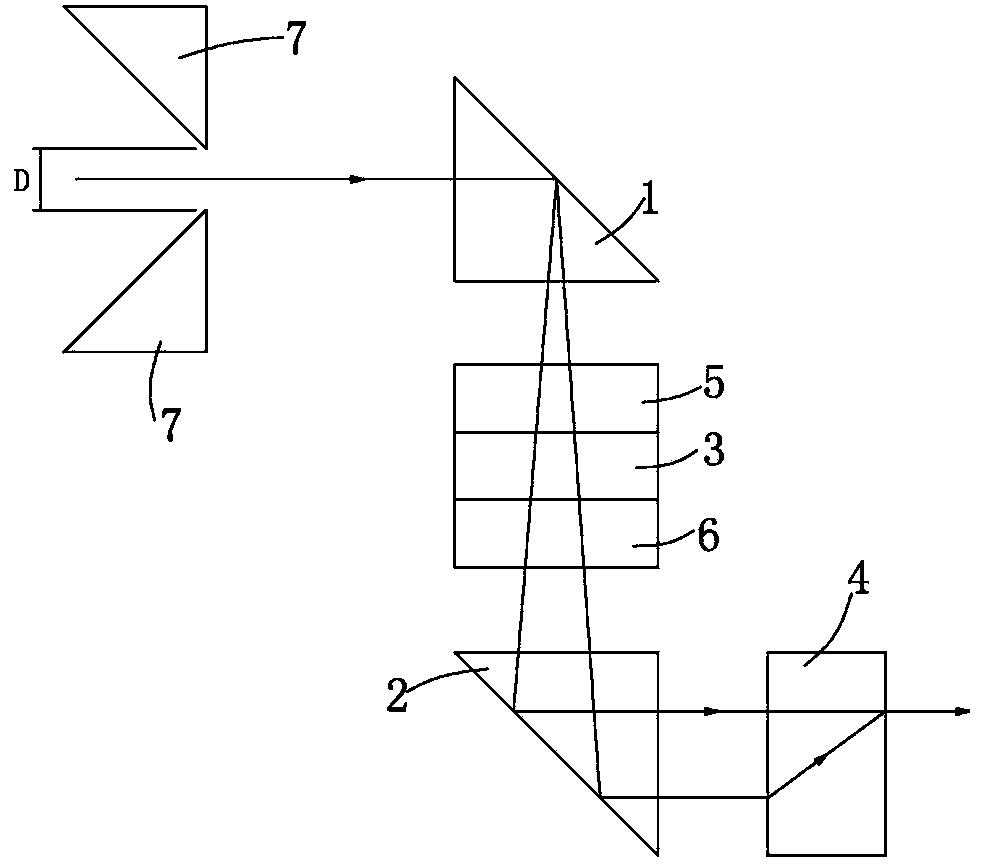

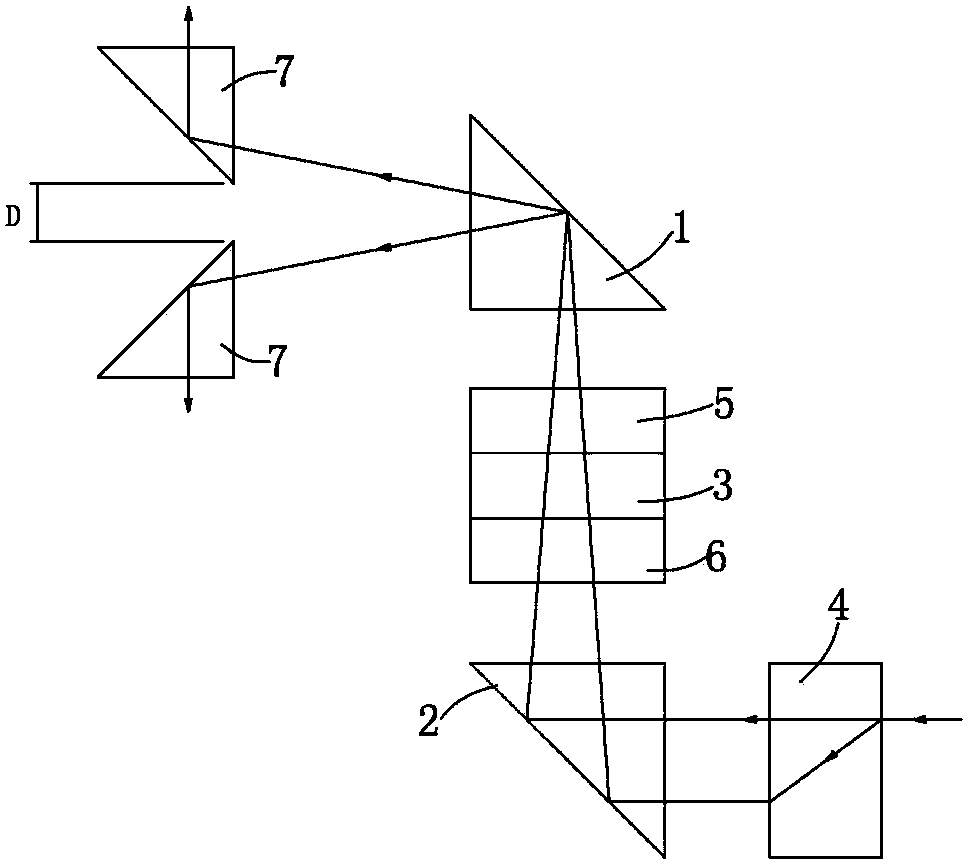

[0018] The present invention adopts the pair of birefringent prisms of reflective polarizing beam splitting prisms to split the light transmitted in the isolator into two polarized lights whose polarization directions are perpendicular to each other, and the two polarized lights have a larger separation angle. The two sub-beams of the return light are further reflected away from the forward transmission light to realize a large-aperture polarization-independent high-power isolator. Specifically, the large-aperture polarization-independent high-power isolator disclosed in the present invention includes a first birefringent prism, a 45° Faraday rotator, a second birefringent prism, and a beam combiner arranged in sequence along the forward transmission direction of the optical path; wherein, the first Both a birefringent prism and a second birefr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com