Air temperature control method in printing and dyeing workshop

A temperature control method and workshop air technology, applied in the field of information, can solve the problems of gray cloth dyeing color chroma value error, gray cloth dyeing unevenness, gray cloth dyeing color chroma value has a great influence, etc., and achieve the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Concrete implementation steps of the present invention are as follows:

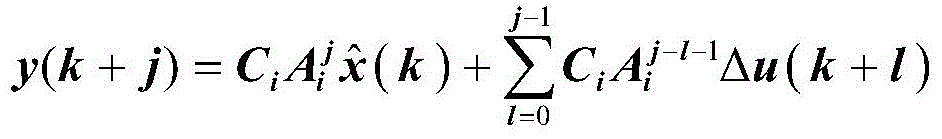

[0064] 1. The establishment of the prediction model of the air temperature control system in the printing and dyeing workshop.

[0065] In the first step, at various typical temperatures such as 5°C, 10°C, 15°C, 20°C, 15°C, 30°C, and 35°C, the valves of the cold water two-way valve, the heating two-way valve and the steam two-way valve are opened. The temperature value is the input control quantity, and the air temperature of the dyeing workshop collected by the temperature sensor is the output quantity. Through the system identification method, the discrete time transfer function model of the air temperature control system of the printing and dyeing workshop is established.

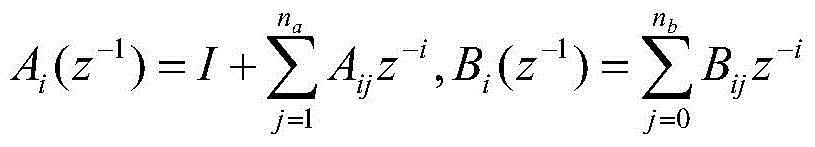

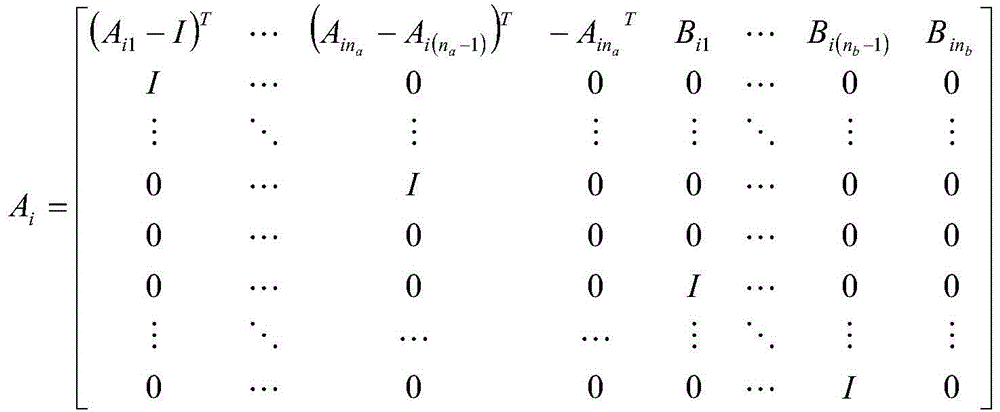

[0066] A i (z -1 )y(k)=B i (z -1 )u(k)

[0067] Wherein y(k) represents the air temperature value of the dyeing workshop; u(k)=[u 1 (k), u 2 (k), u 3 (k)] T is the control input variable at time k, where u 1 (k) rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com