The Control Method of Automatic Lowering of Braided Gear

A technology of automatic descending and control method, applied in the direction of electrical program control, program control in sequence/logic controller, etc., can solve the problems such as the impact or twist of the braided gear, the broken tooth of the braided gear, and the increase of production cost, and achieve Improved quality, high precision, and expensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

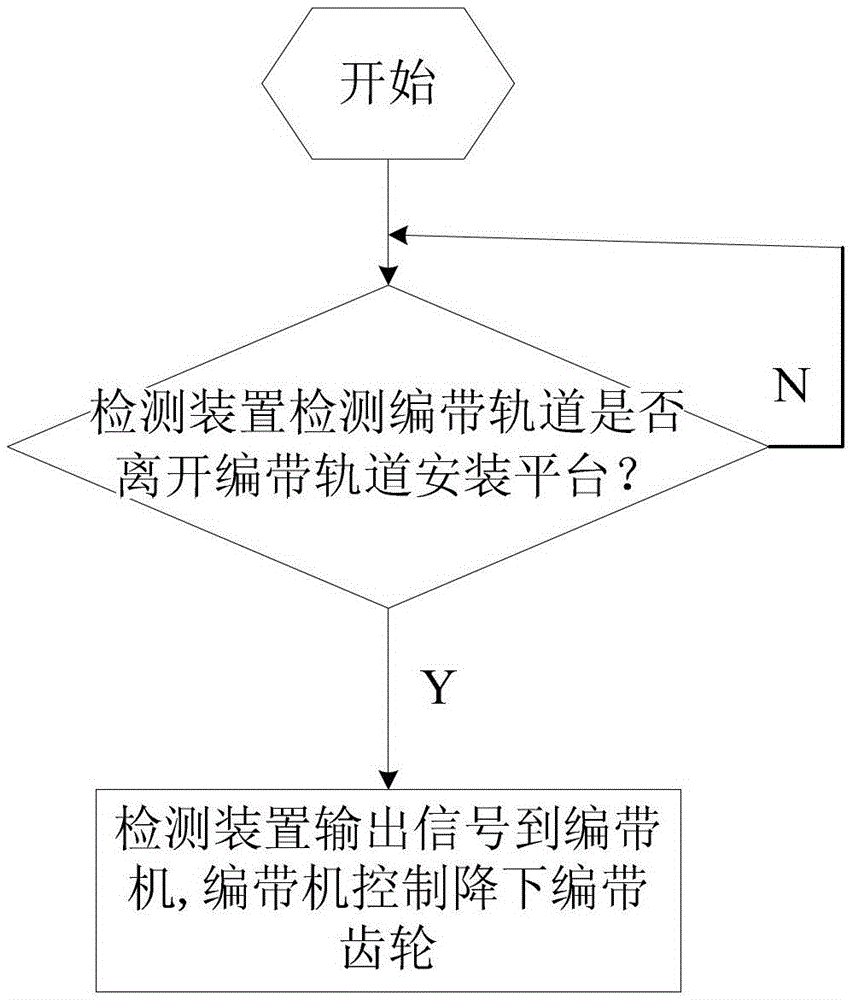

[0015] like figure 1 Shown, the control method that braiding gear of the present invention descends automatically is:

[0016] The detection device detects whether the braiding track has left the braiding track installation platform. If it detects that the braiding track has left the braiding track installation platform, the detection device outputs a signal to the braiding machine, and the braiding machine controls the lowering of the braiding gear; if it is not detected , then continue to loop detection. The detection device outputs a signal to the braiding machine within 0.5 mm distance from the braiding track to the braiding track installation platform. Wherein, the detection device is a sensor, and the sensor is installed on the braided track installation platform. The sensor is a proximity sensor. The sensitivity of the proximity sensor is within 1mm.

[0017] Specifically, the present invention adds a sensor on the existing mechanism of the braiding machine, and ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com