Numerical control machining method

A processing method and parameter technology, applied in the field of numerical control processing methods and devices, can solve the problems of complex process, low production efficiency, repetitive work, etc., and achieve the effects of reducing scrap rate, improving accuracy, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

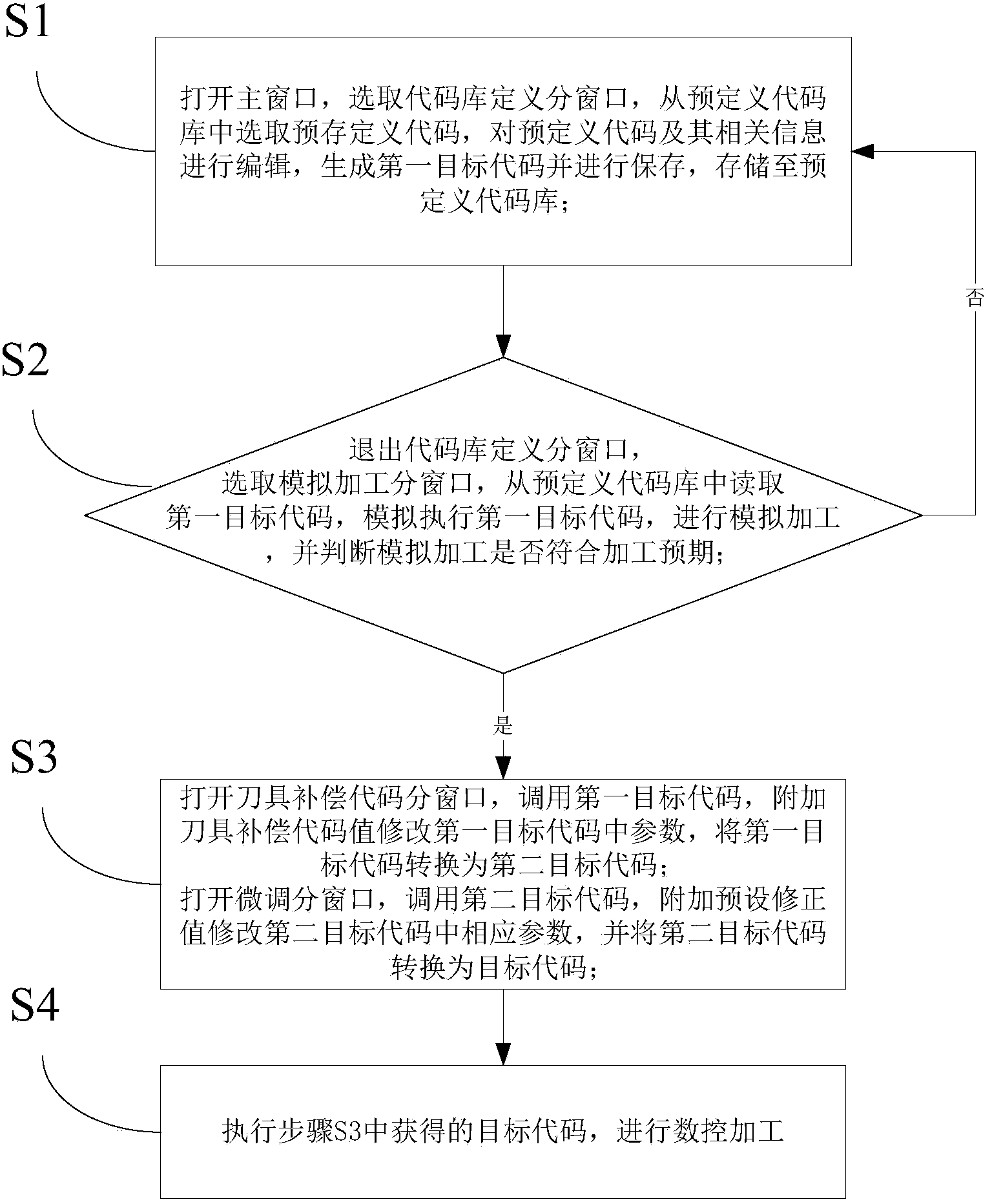

[0014] The embodiment of the present invention provides a kind of numerical control machining method, such as figure 1 shown, including the following steps:

[0015] S1. Open the main window, select the code library definition sub-window, select the pre-stored definition code from the predefined code library, edit the predefined code and its related information, generate the first object code and save it, and store it in the predefined code library ;

[0016] S2. Exit the code base definition sub-window, select the simulation processing sub-window, read the first target code from the predefined code base, simulate the execution of the first target code, perform simulated processing, and judge whether the simulated processing meets the processing expectations; if the simulation If the processing meets the processing expectations, go to step S3. If the simulated processing does not meet the processing expectations, return to step S1, and proceed to step S2 in sequence until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com