Double-screw pelletizer based on inorganic powder

An inorganic powder, twin-screw technology, applied in the field of raw material processing equipment, can solve the problems of limited single-screw pressure, slow down processing speed, reduce production efficiency, etc., and achieve the effects of fast pelletizing, prolonging service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] For the convenience of description, the "left" and "right" referred to below are consistent with the left and right directions of the drawings themselves, but they do not limit the structure of the present invention.

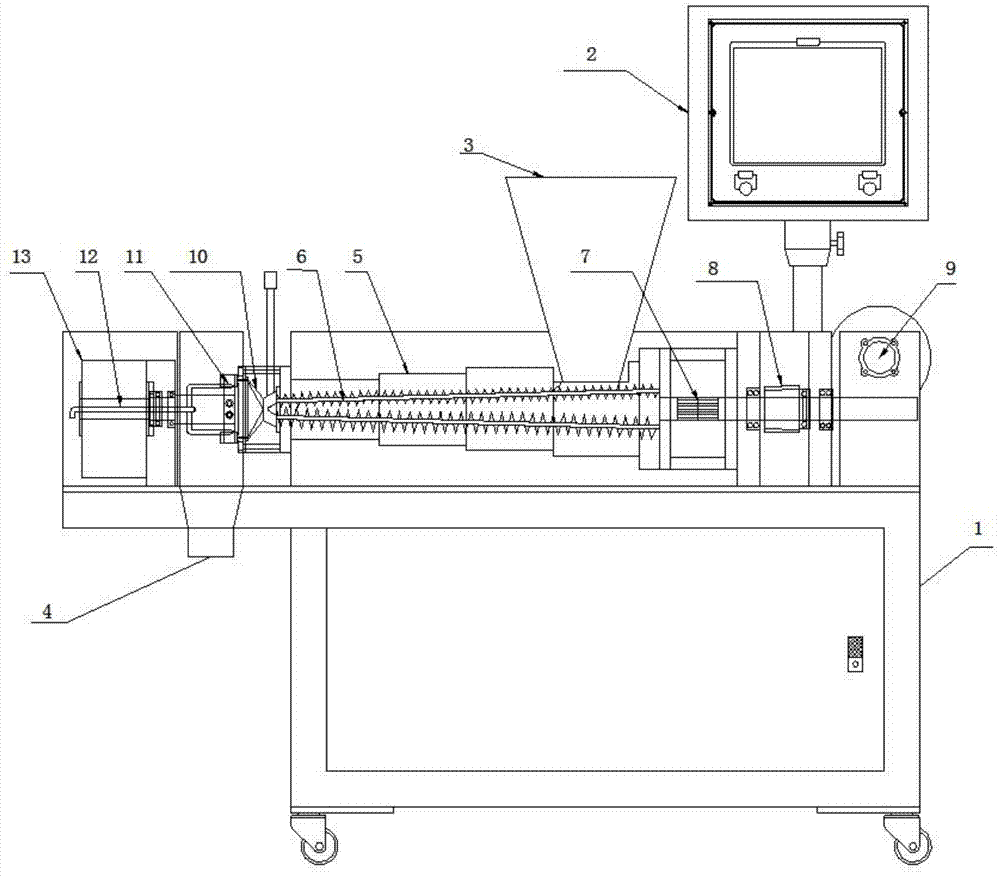

[0014] Such as figure 1 As shown, the bed 1 is provided with an operation panel 2 upright on the right side of the bed 1, and the operation panel 2 is equipped with a machine tool switch. A twin-screw extrusion device is provided in the middle of the bed 1, which consists of a material chamber 5 fixed above the bed, a twin-screw 6 horizontally installed in the material chamber 5, a motor 9 that drives the twin-screw 6, and a connection The motor 9 is composed of the twin-shaft distribution gearbox 8 of the twin-screw 6; wherein, the distance between the twin-screw 6 gradually becomes smaller along the processing direction, and when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com