Explosive welding method for solving problem that explosion points of rare and precious metallic composite plates are not in fit

A composite material plate and explosive welding technology, which is applied in the field of composite material manufacturing, can solve problems such as the non-bonding of the composite layer and the substrate, and achieve the effects of reducing energy, easy operation, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

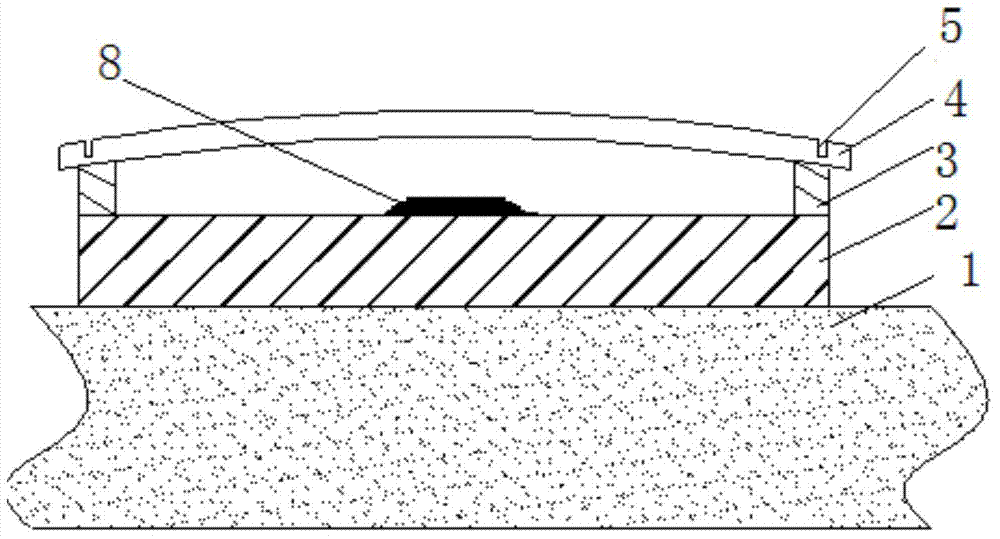

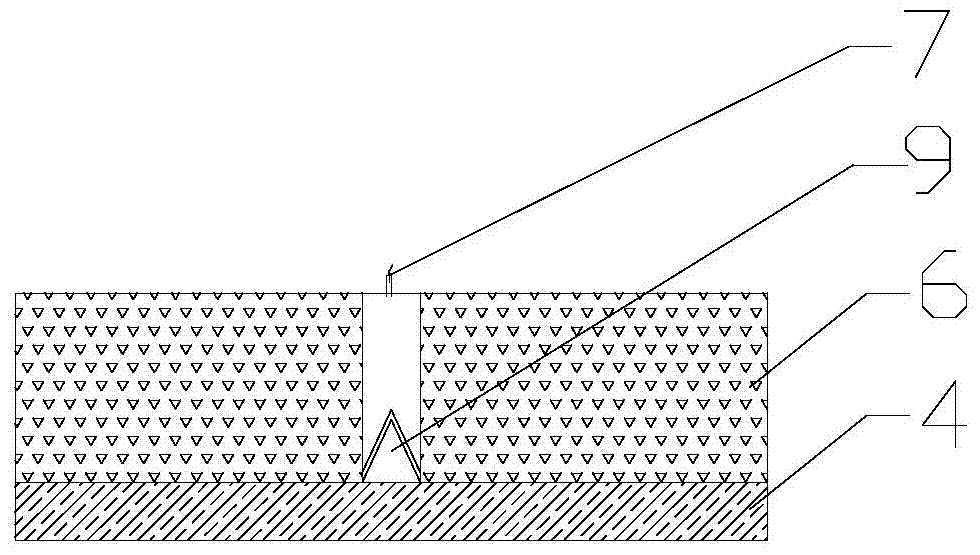

[0023] As shown in the figure, the foundation 1, the base layer 2, the support 3, the second cladding layer 4, the cladding layer slotting 5, the composite layer rejection area P after the first explosion, the explosive 6, the detonator 7, the first cladding layer 8, the detonation Point 9.

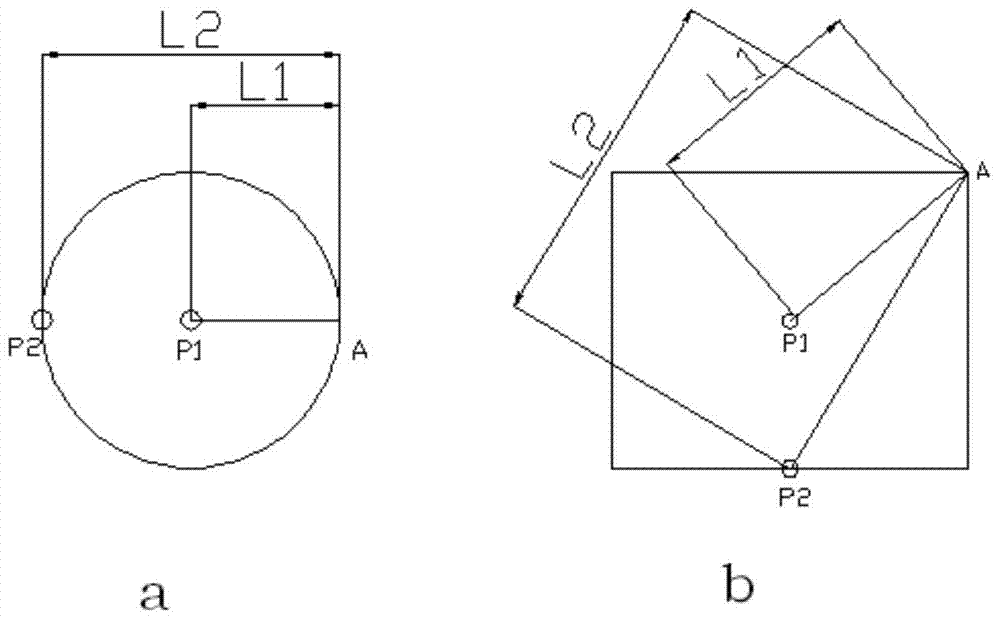

[0024] The method of composite explosion plate is already a conventional method in this field. Generally, the base layer is made of thicker (1-20cm) carbon steel, and the cladding layer is generally a rare and precious metal that cannot be melted and welded with the base metal, including various corrosion-resistant alloy steels, and even It is INCOLOY, Babbitt alloy, Monel alloy steel. Certainly the material of the clad plate of secondary explosion will be the same. The invention also provides a method of weakening the edge effect during the second explosion. Groove the composite layer on the non-bonded surface (such as figure 2 In the upper right corner, the position of the groove co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com