Unpowered stripping magnetic strip scalding mechanism of automatic film laminating point welding machine

A spot welding machine and hot-hot technology, which is applied in the fields of pasting and decorative arts, can solve the problems that hinder the development of the card making industry, the position of the film is not accurate, and the quality of the card making is unstable, so as to reduce the labor intensity of workers and save the workshop Space and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

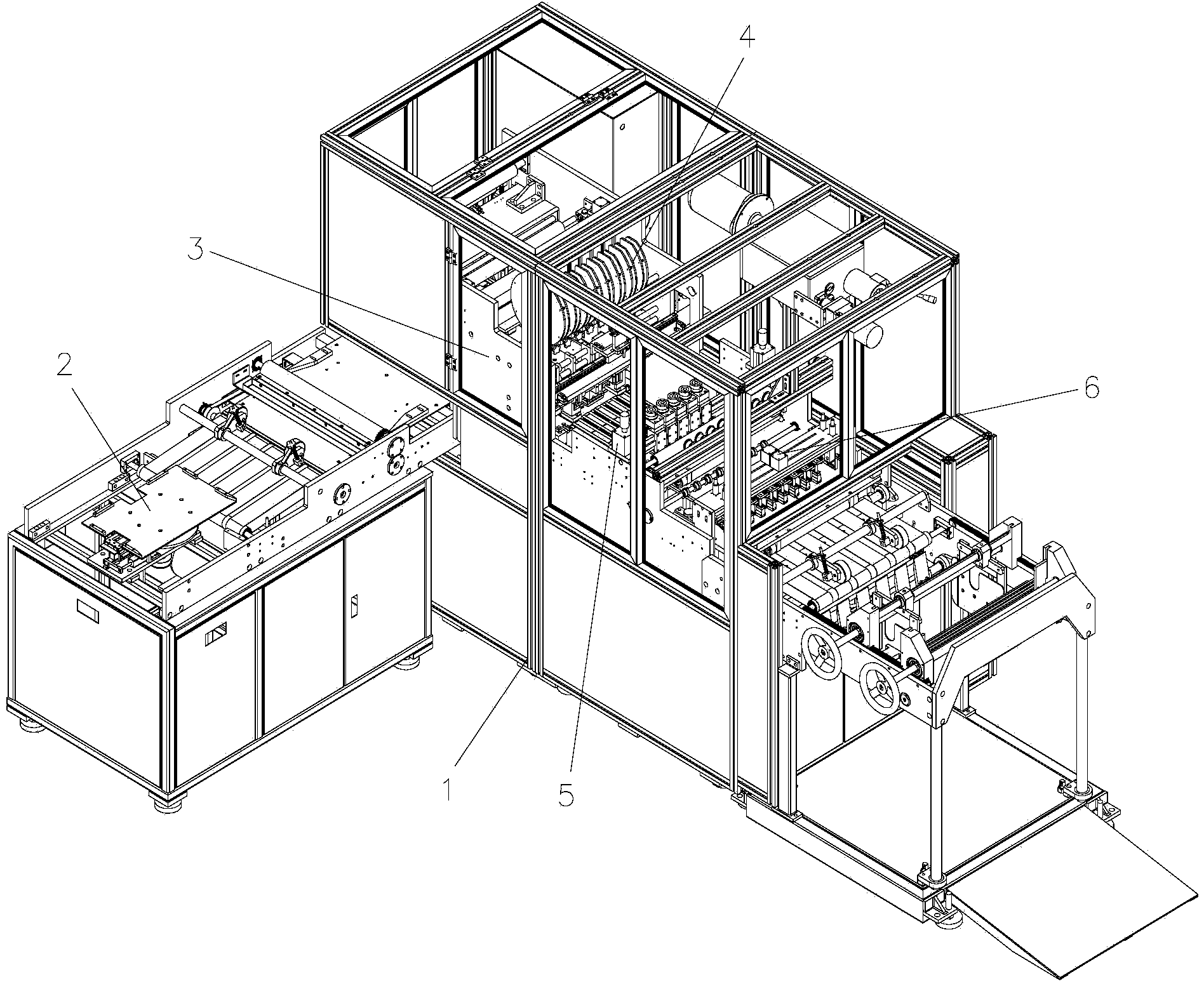

[0036] see Figure 1 to Figure 5 , an automatic lamination film spot welding machine, which includes a frame 1, a feed mechanism 2, an automatic film-on mechanism 3, a disk mechanism 4, a non-powered stripping magnetic strip scalding mechanism 5, a one-point cutting magnetic strip mechanism 6.

[0037] The rack 1 is placed on the ground.

[0038] The feeding mechanism 2 is placed on the left side of the frame 1 .

[0039] The automatic film loading mechanism 3 is installed on the frame 1 near the rear end.

[0040] The disk mechanism 4 is installed on the frame 1 near the middle, and is located at the front side of the automatic film loading mechanism 3 .

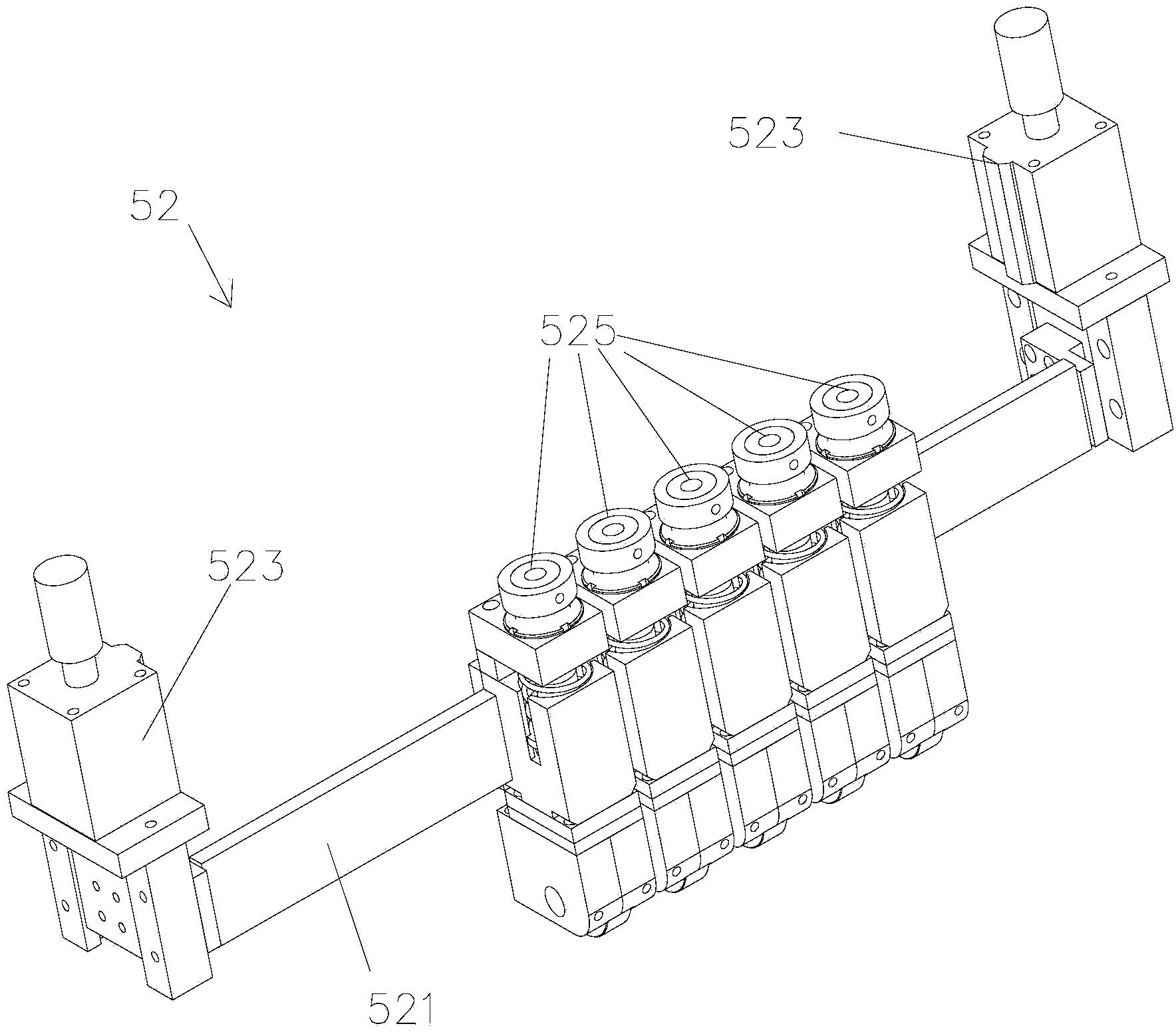

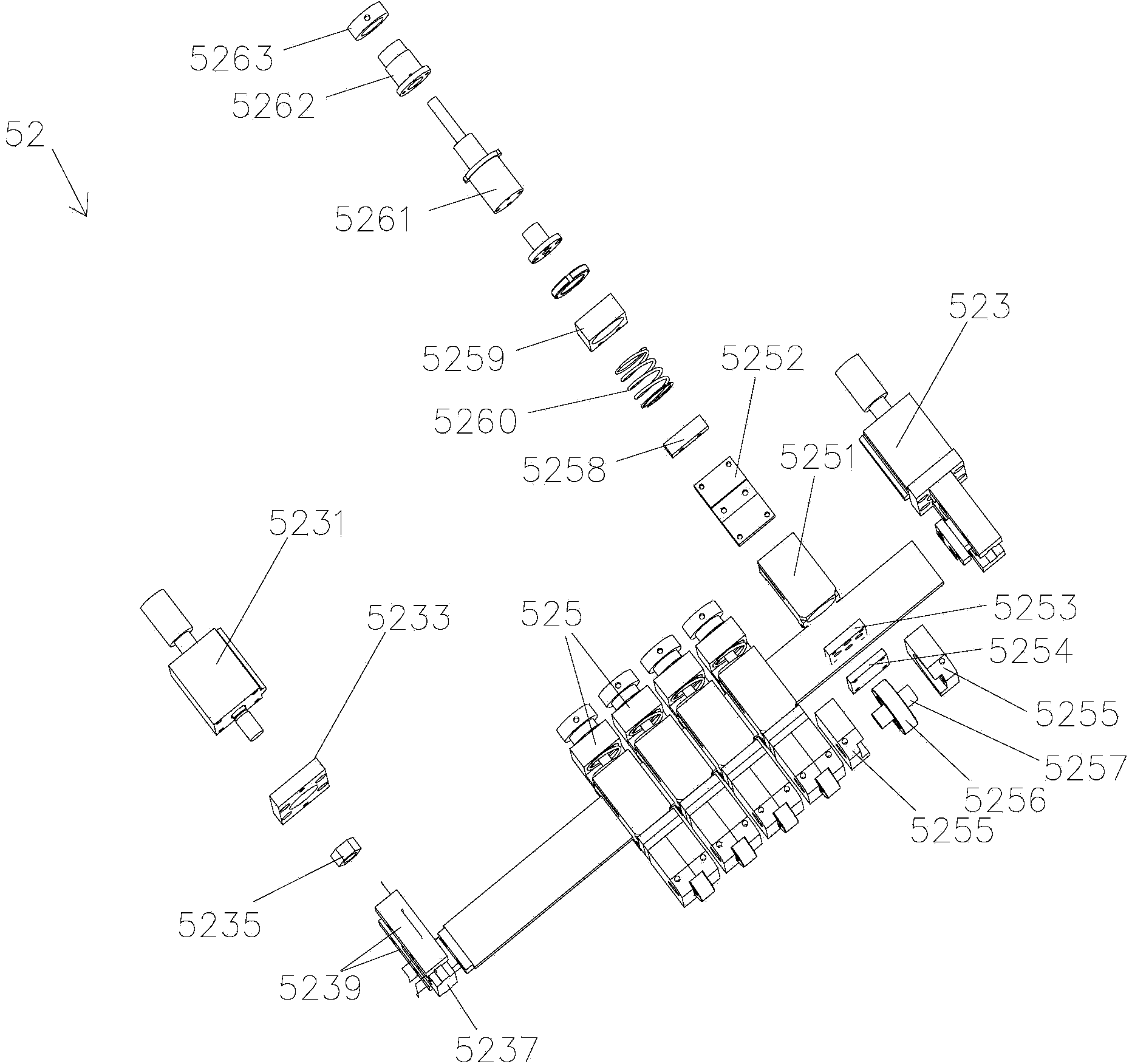

[0041] This unpowered stripping magnetic strip scalding mechanism 5 is installed on this frame 1, is positioned at the front side of this magnetic disk mechanism 4.

[0042] The point-cutting magnetic strip mechanism 6 is installed on the frame 1 and is positioned at the front side of the unpowered stripping magnetic st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap