In-wheel Motor Assembly

An in-wheel motor and assembly technology, applied in the direction of motion deposition, control devices, power devices, etc., can solve the problems of inability to use wheels in the in-wheel motor system, cost rise, etc., to achieve easy maintenance and management, increase the degree of freedom, and improve The effect of fuel efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the drawings. However, it should be pointed out that the following examples are provided to help understand the present invention, and the scope of the present invention is not limited to the following examples. In addition, the following embodiments are provided to more completely explain the present invention to those skilled in the art, and detailed descriptions of known structures that are judged to unnecessarily obscure the technical gist of the present invention are omitted.

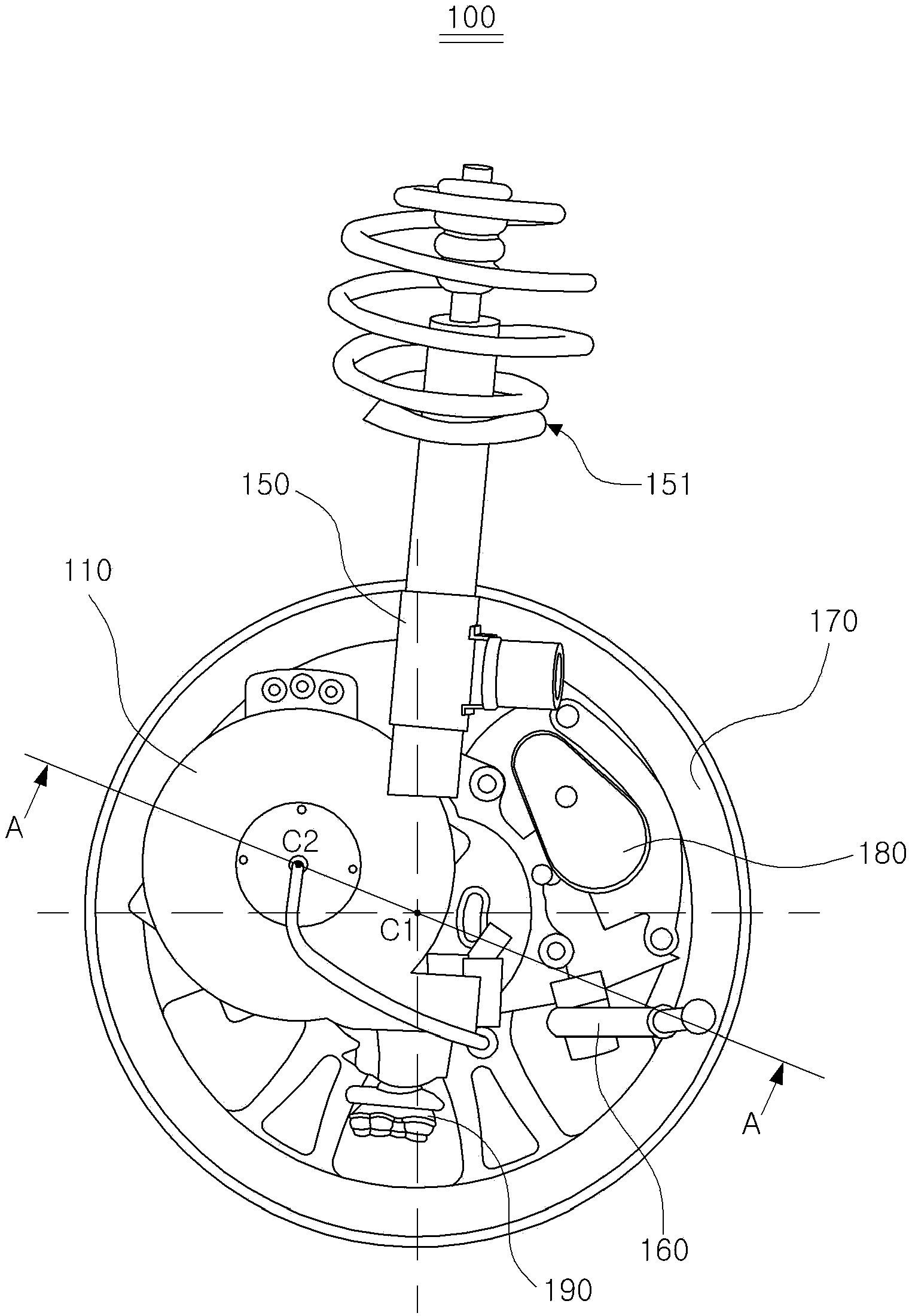

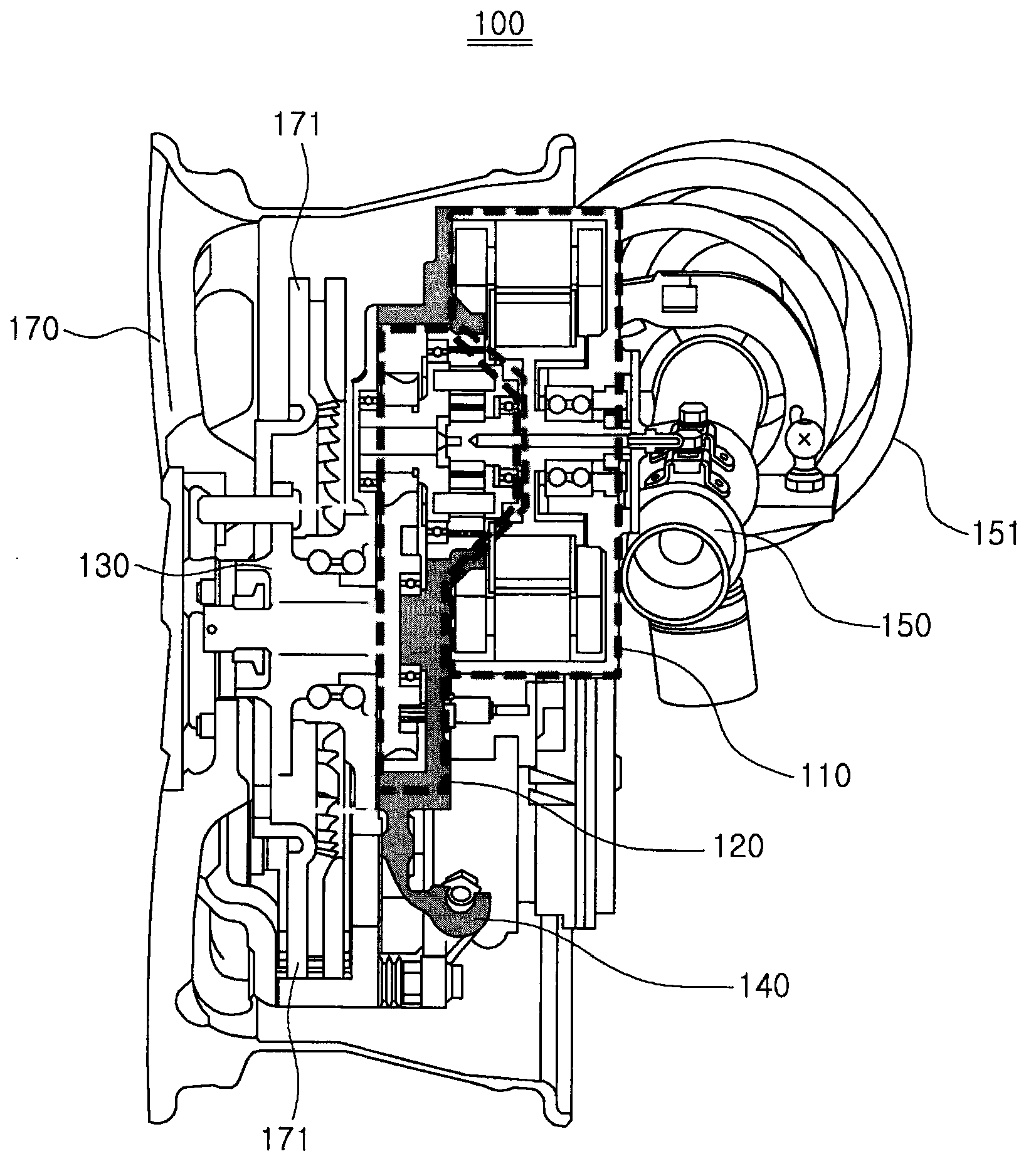

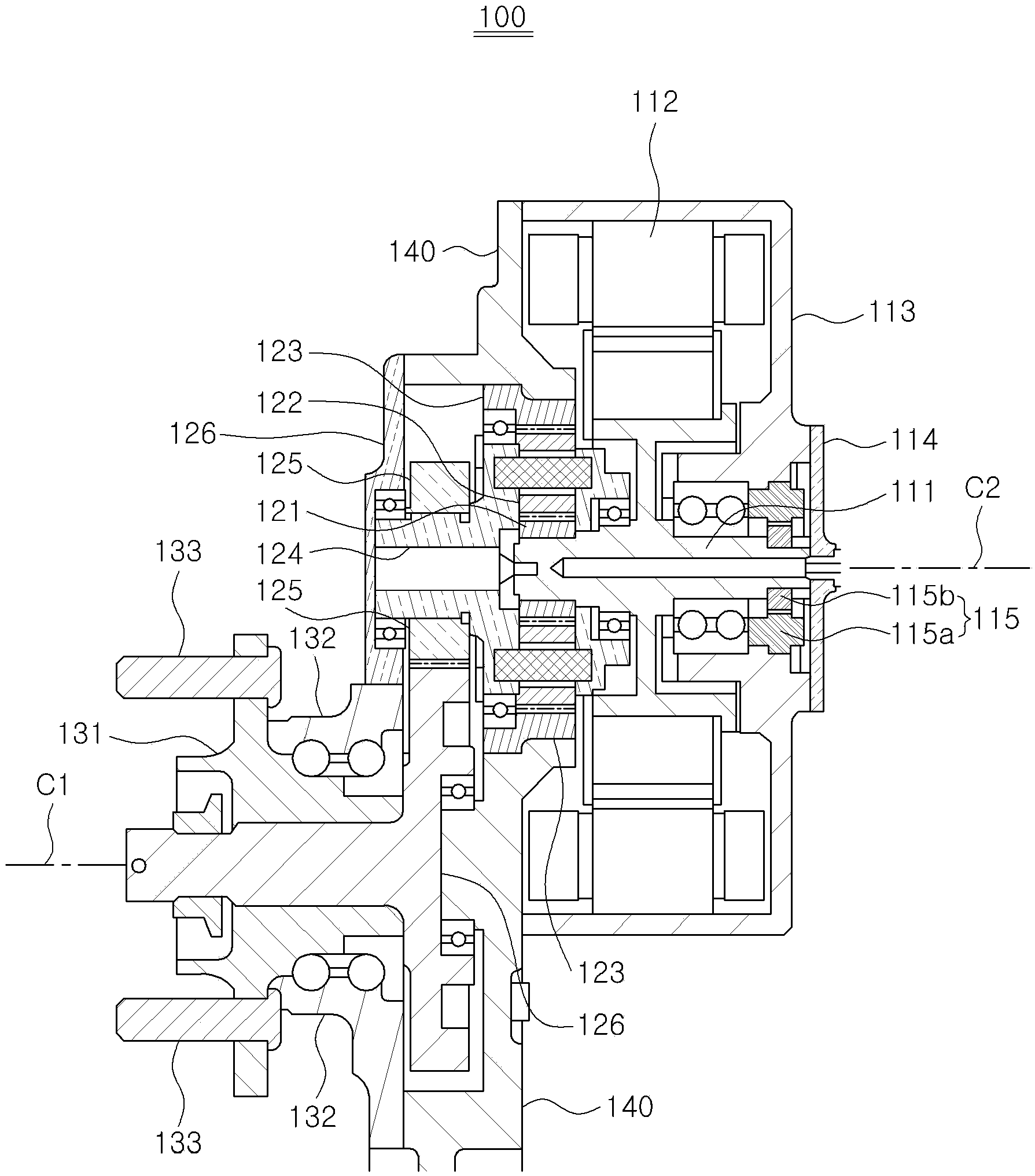

[0021] figure 1 is a configuration diagram of an in-wheel motor assembly according to an embodiment of the present invention.

[0022] Such as figure 1 As shown, in terms of the in-wheel motor assembly 100 of this embodiment, the rotation axis C2 of the motor assembly 110 and the rotation axis C1 of the wheel 170 or axle can be disposed at different positions. That is, the rotation axis C2 of the motor assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com