Novel stacker crane

A palletizer, a new type of technology, is applied in the direction of object stacking, object destacking, transportation and packaging, etc. It can solve the problems of unfavorable mechanized production, need for manual handling, and high labor intensity, etc., and achieve low cost and low cost. The effect of maintaining synchronization and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

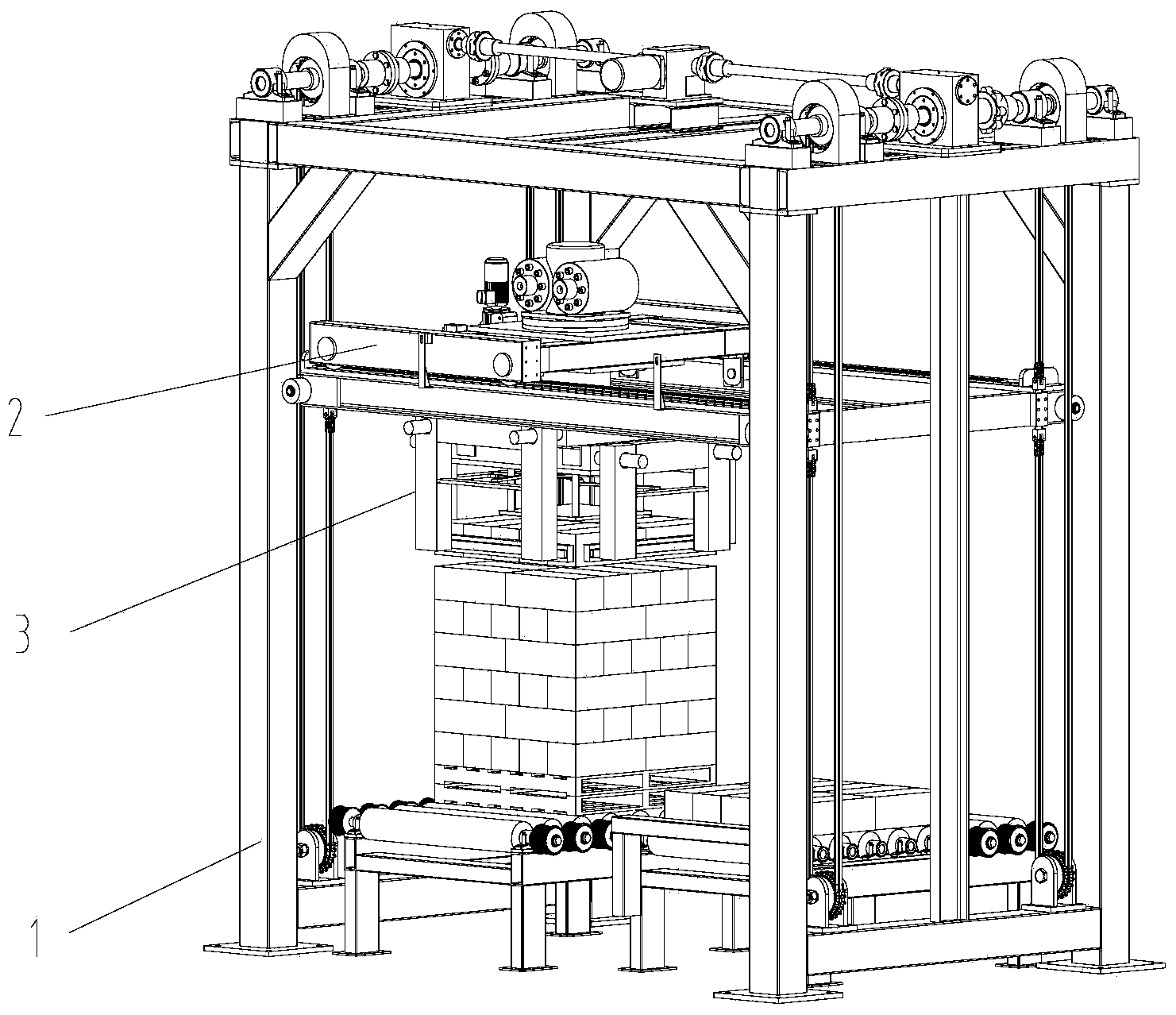

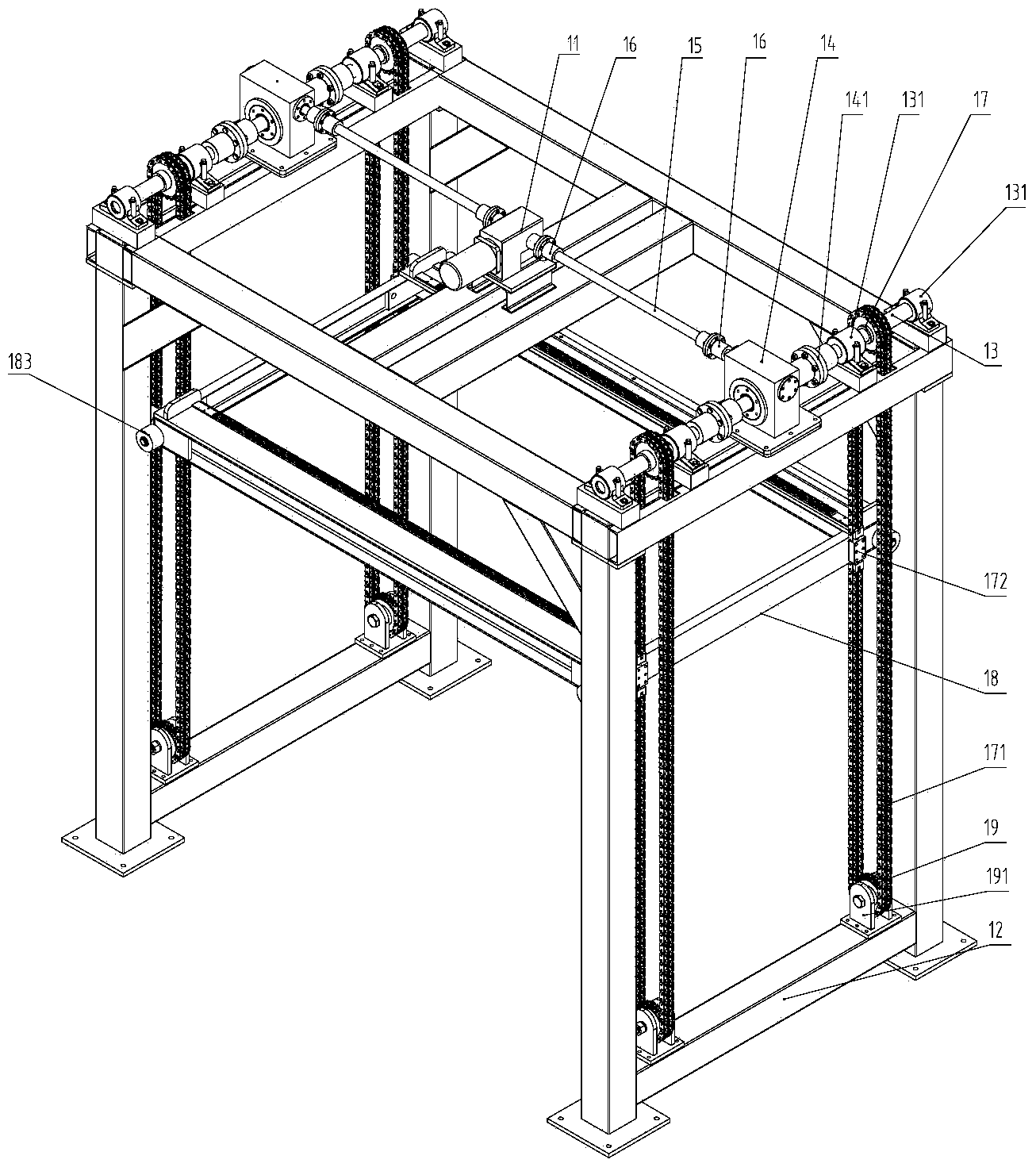

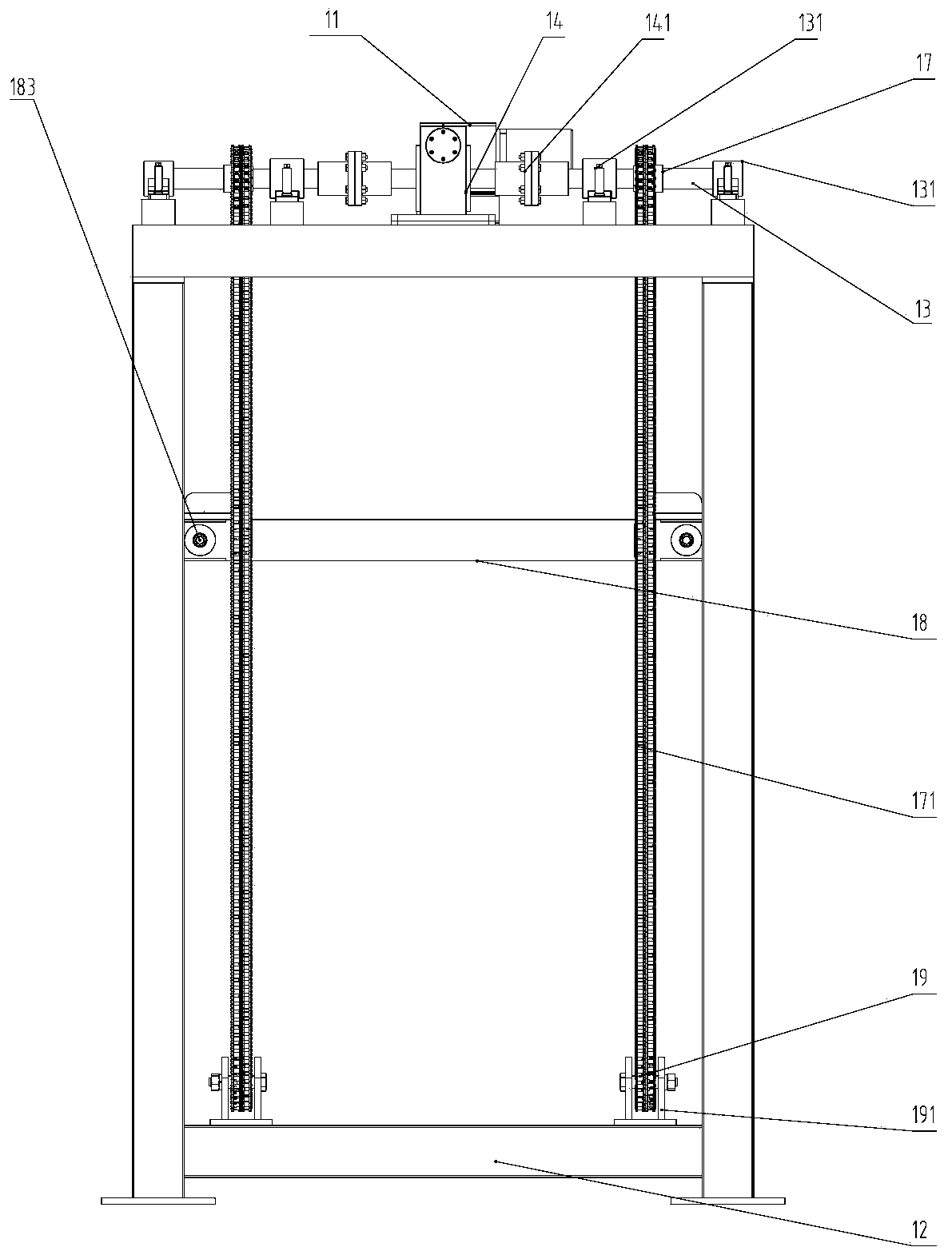

[0028] Embodiment 1 A new type of palletizer according to the present invention includes a lifting traction device 1, a horizontal traction device 2 and a clamping claw mechanism 3, and the lifting traction device 1 pulls the lifting frame 18 to move up and down; the horizontal traction device 1 moves up and down; The traction device 2 is installed on the lifting frame 18, and moves horizontally along the lifting frame 18; the clamping claw mechanism 3 is connected to the rotating device of the horizontal traction device 2, and moves together with the horizontal traction device 2;

[0029] The lifting traction device 1 includes a reduction motor 11, a frame 12, a driving sprocket shaft 13, a worm gear reduction device 14, a reduction motor output connection shaft 15, a motor output connection shaft coupling 16, a lifting driving sprocket 17, a lifting Frame 18, tensioning sprocket 19, described deceleration motor 11 is fixed in the middle of frame 12, and described deceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com