Warm deformation process for improving strength and damage resistance of erbium-containing aluminum-magnesium alloy

An aluminum-magnesium alloy, damage-resistant technology, applied in the field of warm deformation process, can solve the problems of reducing dislocation density, reducing damage resistance, and strength, achieving great guiding significance, solving contradictions, and improving strength and damage resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

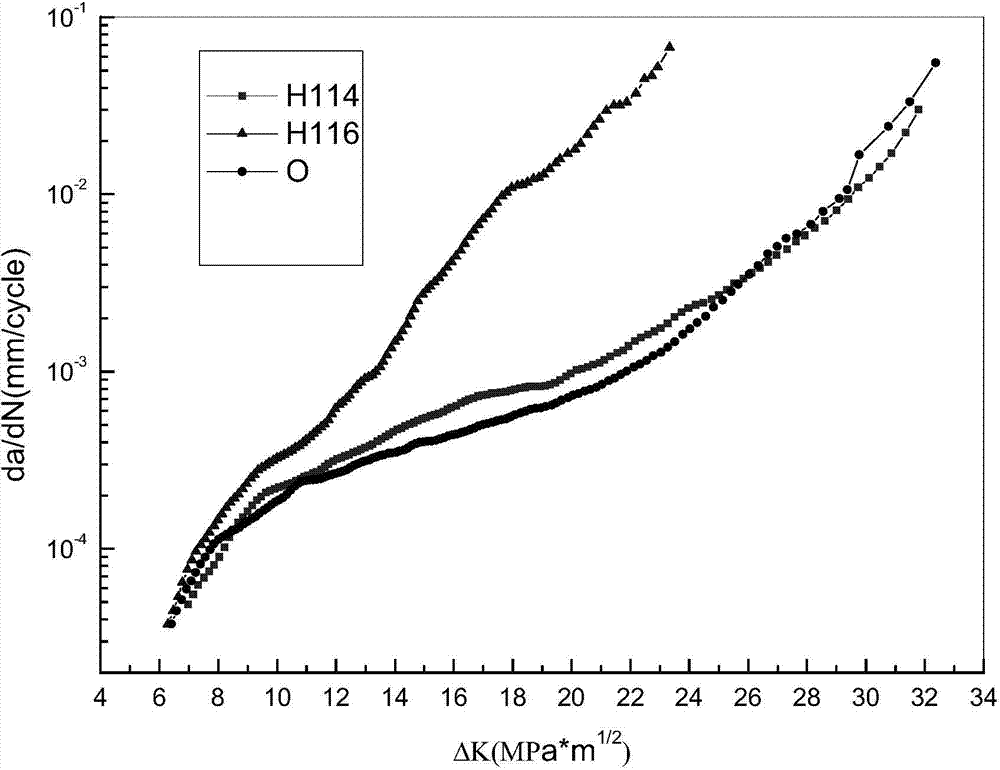

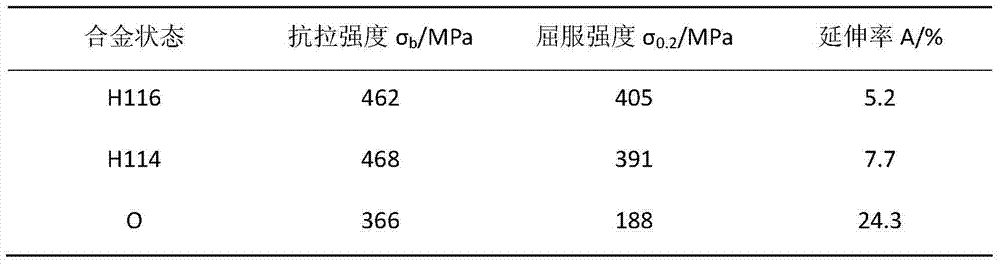

[0013] For a mass percentage content: Mg, 6.0%; Mn, 0.5%; Zn0.8%; Zr, 0.2%; Er, 0.2%, unavoidable impurities ≤ 0.5%, the balance is Al-containing aluminum magnesium The alloy material is hot-rolled at 410±20°C with a deformation of 90%, then air-cooled to room temperature, with a thickness of 10mm, and then kept at 230°C for 1 hour, and then warm-formed at the holding temperature, with a deformation of 60%, and a state of 4mm thickness, recorded as H114 . Tensile tests were carried out on the deformed materials, and the data are listed in Table 1. The fatigue crack growth rate test was carried out on the deformed material, and the data are shown in figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com