Novel high-speed carding machine

A high-speed, new type of technology, used in fiber processing, deburring devices, textiles and papermaking, etc., can solve the problems of reduced production quality, affecting the stability and speed of carding machine operation, etc., to ensure production quality, stability and stability. high speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

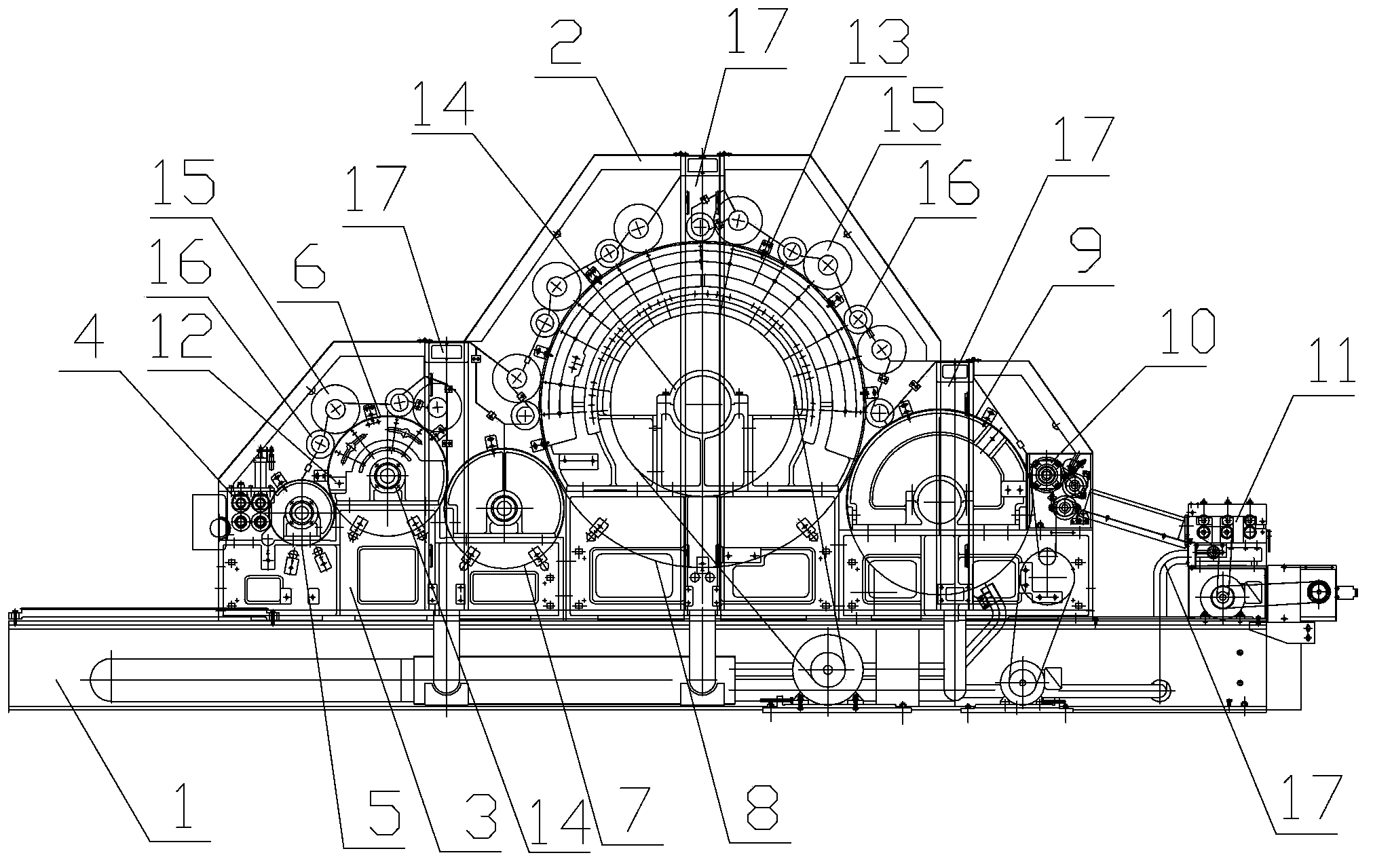

[0007] Novel high-speed carding machine of the present invention, as figure 1 As shown, it includes a base 1 and a protective cover 2 installed on the base 1. The base 1 in the protective cover 2 is symmetrically installed with a substrate 3, and the protective cover 2 is sequentially installed with a feeding roller 4, an opening Loose roller 5, breast cylinder 6, transfer roller 7, large cylinder 8, doffer 9, three-roller hair stripping device 10, top drafting device 11 is also installed on the base 1 behind the protective cover 2, breast cylinder 6 and two large cylinder wall panels 12 and two large cylinder wall panels 13 are arranged symmetrically in the protective housing 2 on both sides of the large cylinder 8, and both the breast cylinder wall panels 12 and the large cylinder wall panels 13 are installed On the substrate 1, both the breast cylinder wallboard 12 and the large cylinder wallboard 13 are provided with shaft seats 14, and the two ends of the breast cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com