Eccentric swing impeller engine air intake pressurizer

An engine and supercharger technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve problems such as increased engine output power, large cooling installation space, and unstable intake pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

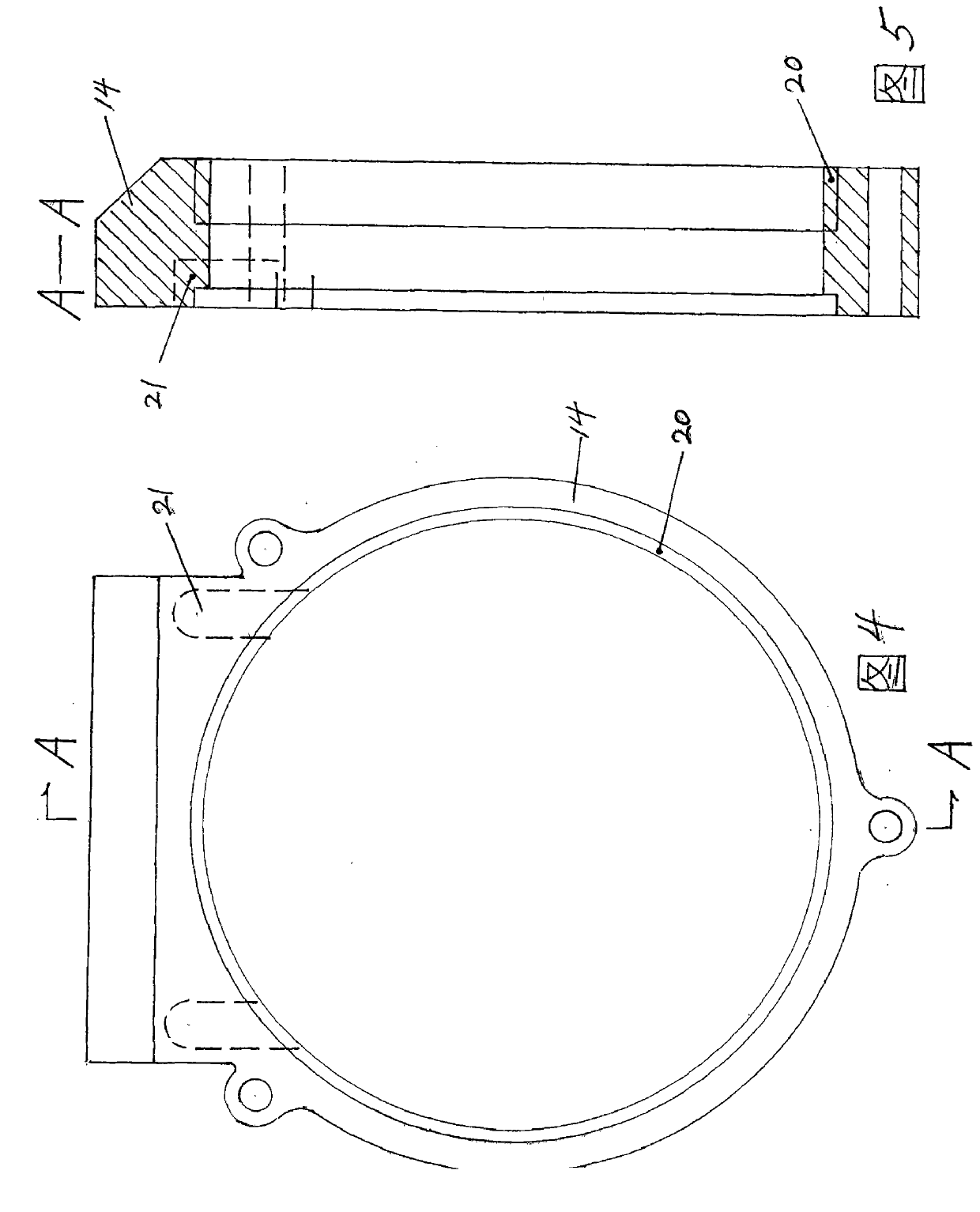

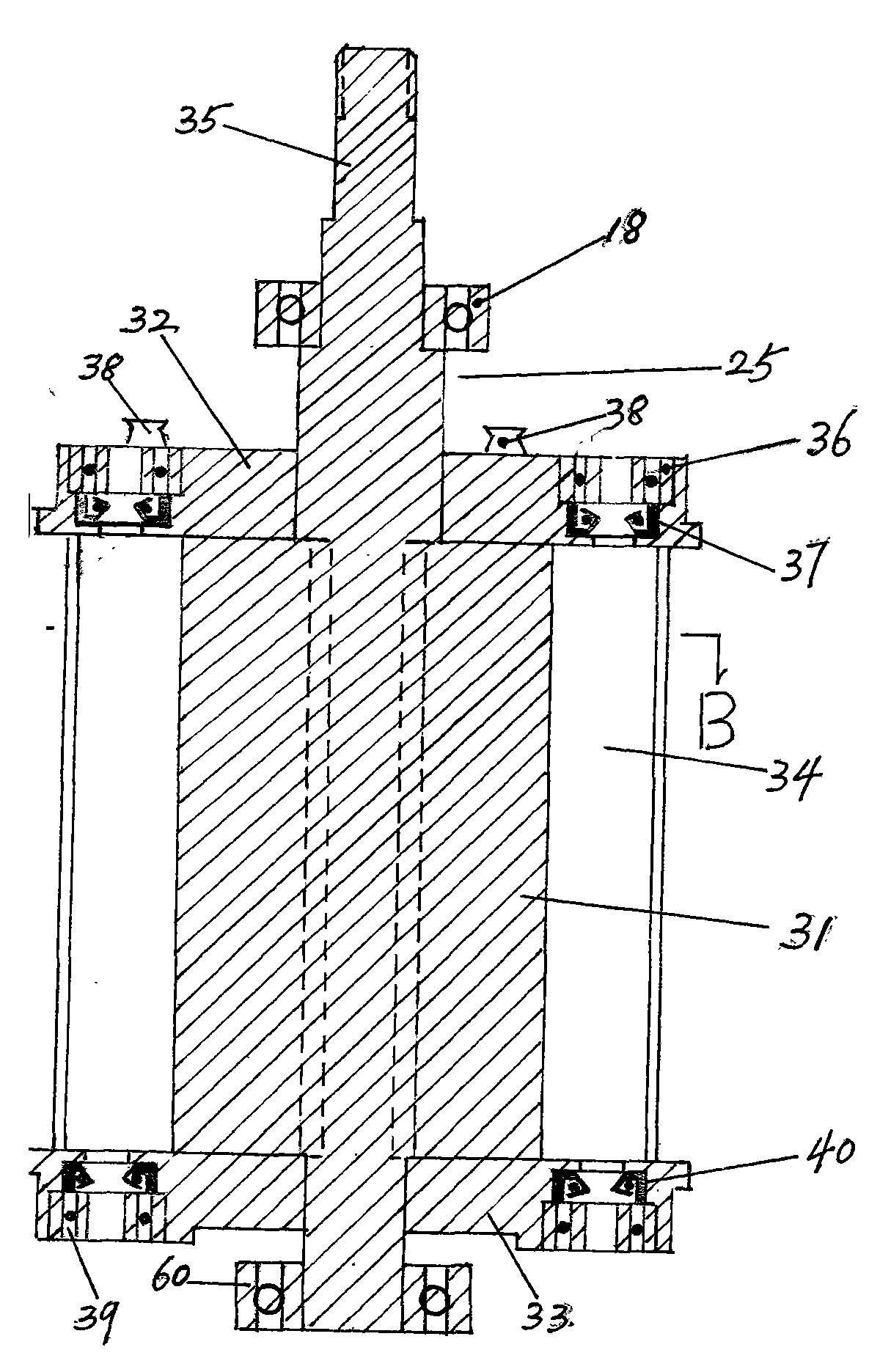

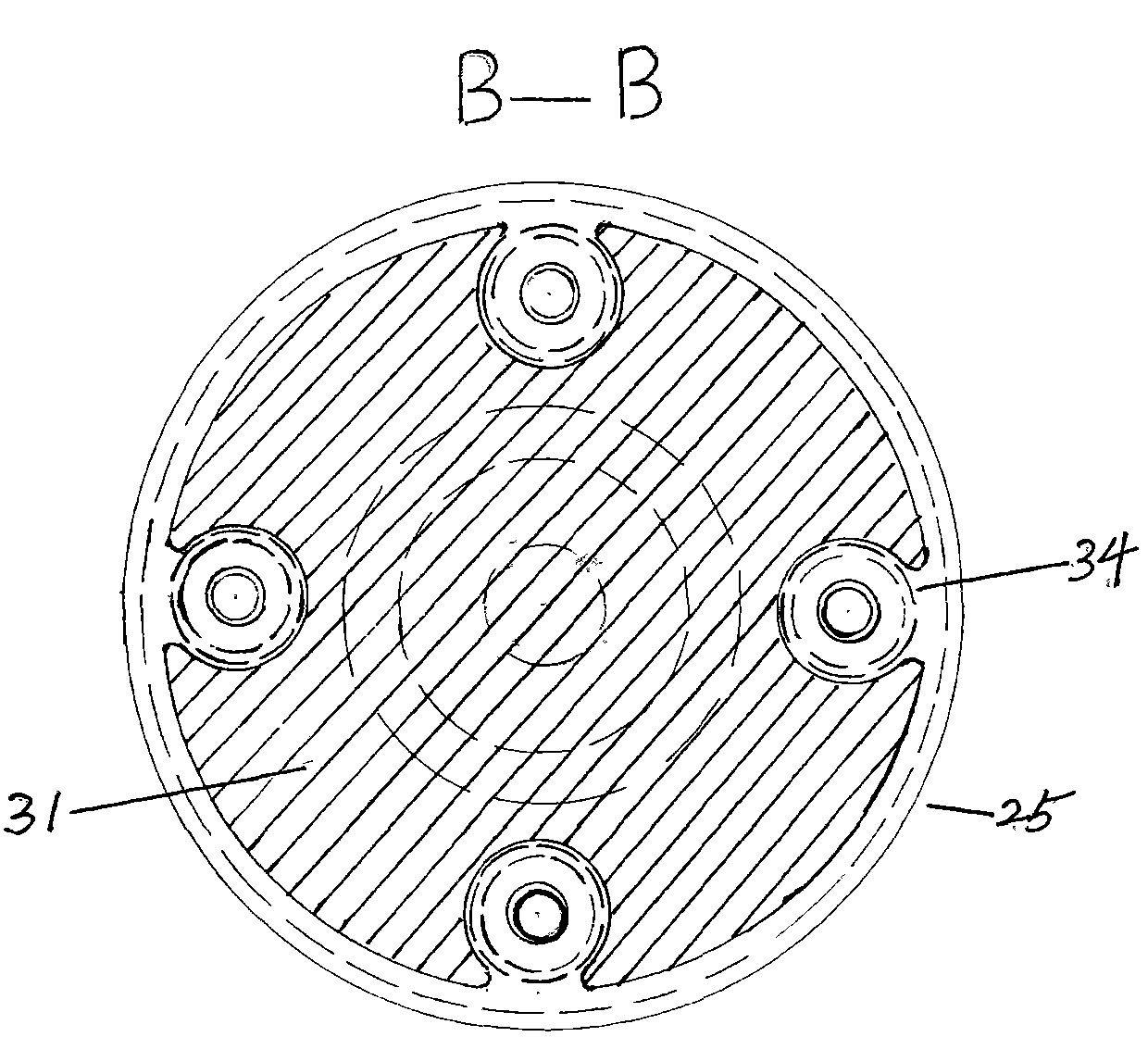

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. as attached figure 1 The shown eccentric swing vane engine air intake supercharger is mainly composed of a driving mechanism 1, a swing vane rail chamber 2, an eccentric swing vane squeeze pressurization chamber 3 and a pressure relief valve 4, a base 30, a lower chamber cover 29, a chamber Body 28, upper cavity cover 27, swing leaf rail chamber cover 14, swing leaf rail chamber cover plate 13 and drive mechanism casing 9 are superimposed sequentially and fastened together with bolts, and drive mechanism 1 is located in drive mechanism casing 9, and swing leaf rail chamber 2 is located between the swing vane rail chamber cover plate 13 and the upper chamber cover 27, and the eccentric swing vane squeeze pressurization chamber 3 is located between the upper chamber cover 27 and the base 30. The driving mechanism 1 is composed of a pulley 5, a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com