clutch

A clutch and clutch hub technology, applied in the field of clutches, can solve the problems of high cost, time-consuming and complicated manufacturing, and achieve the effect of simple cost, reduced structural space and improved liquid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

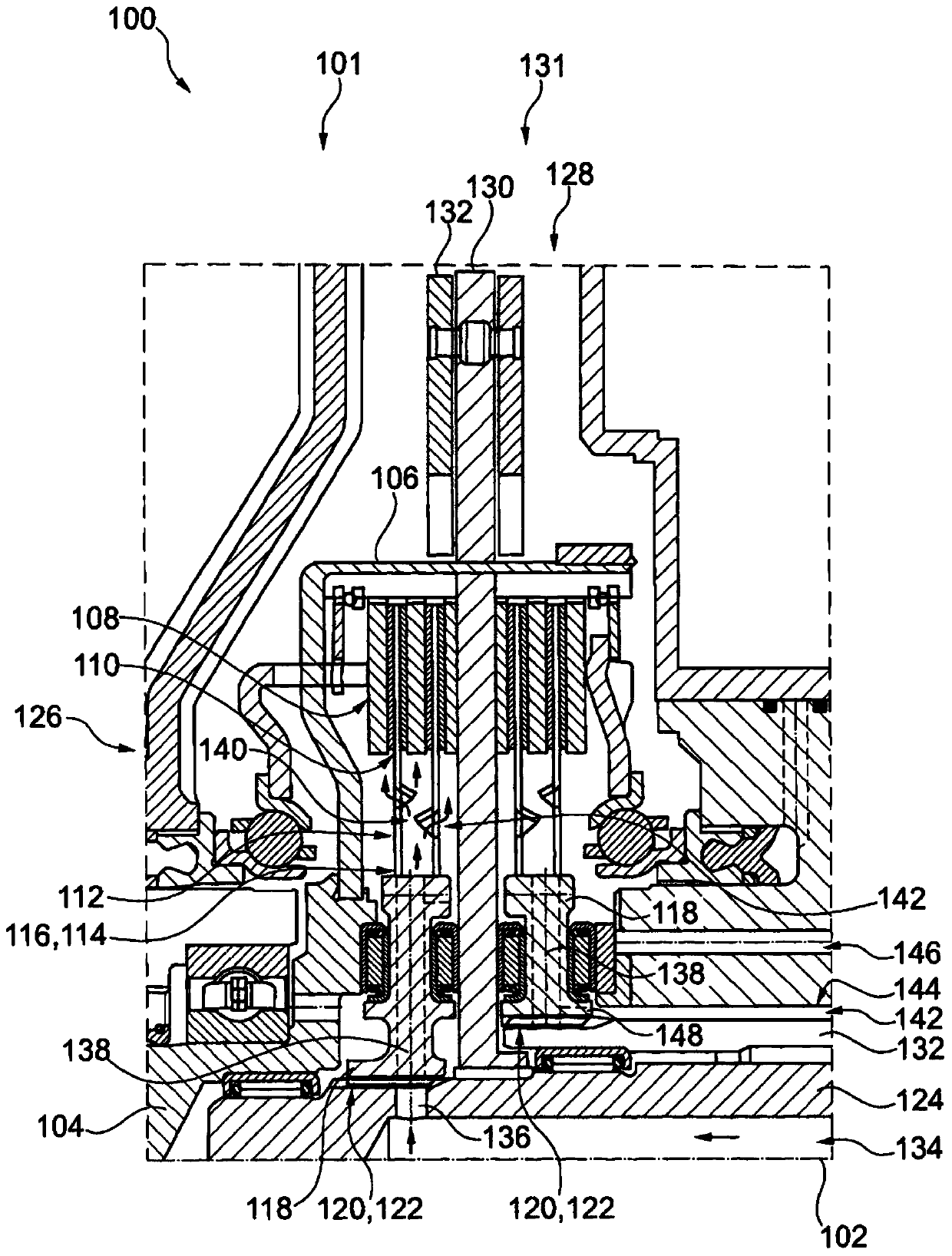

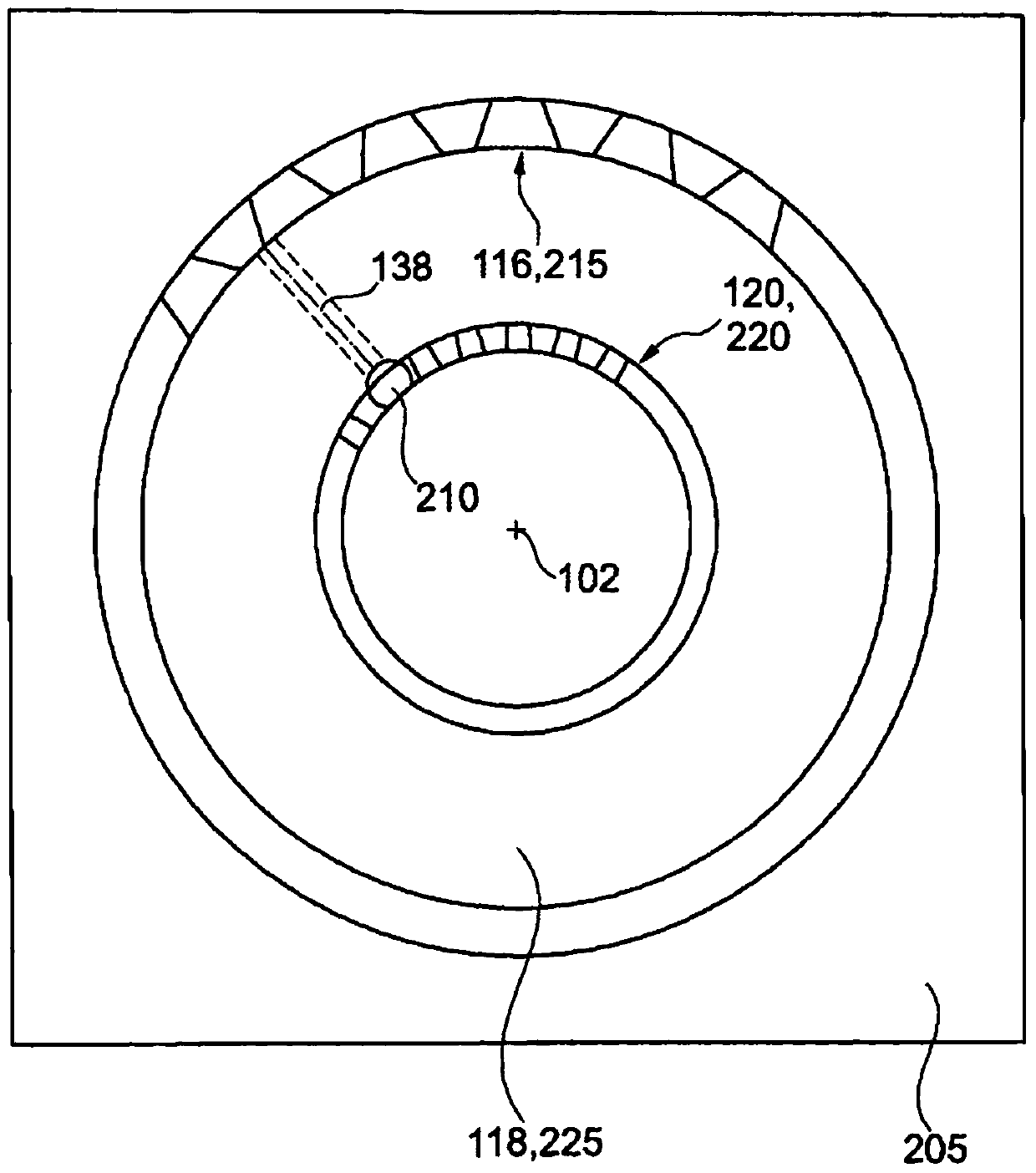

[0023] figure 1 A clutch 100 is shown in half section. The clutch 100 has an axis of rotation 102 , wherein only the elements arranged above the axis of rotation 102 are shown. The illustrated clutch 100 is a double clutch comprising two separate clutches 101 and 131 , which are arranged axially relative to one another here by way of example. In other embodiments, however, the invention can also be provided on a double clutch or a single clutch with a radial configuration.

[0024] A drive shaft 104 is provided for connection with a drive motor. The drive motor may be, for example, part of a drive train in a motor vehicle. The drive shaft 104 is rotationally coupled to a clutch housing 106 , which extends cup-shaped and symmetrical in the axial direction with respect to the axis of rotation 102 . The clutch housing 106 has radial projections or grooves on its radially inwardly directed surface for a form-fitting engagement with the friction elements 108 . The friction ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com