Transformer vibration monitoring system based on wireless sensing technology and testing method

A technology of vibration monitoring system and wireless sensing technology, applied in vibration measurement in solids, signal transmission system, measurement of vibration, etc., can solve the problems of heavy wiring workload, poor flexibility, high cable cost, etc., and achieve easy operation and accuracy The effect of high performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

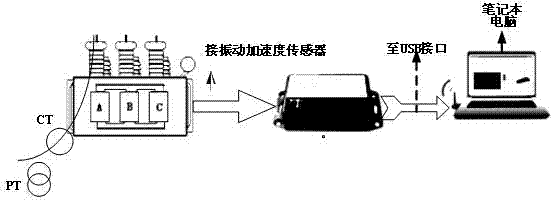

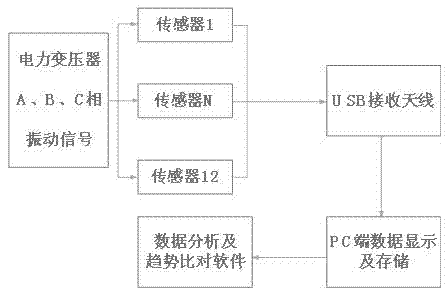

[0034] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0035] Such as Figure 1-5 As shown, a transformer vibration monitoring system based on wireless sensor technology of the present invention includes a transformer vibration monitoring unit, a vibration data receiving device and a computer device connected in sequence with the transformer vibration monitoring unit, and the transformer vibration monitoring unit uses To collect vibration signals and transformer temperature at each measuring point on the surface of the transformer; the transformer vibration monitoring unit includes a single-chip microcomputer and a data sending device connected to the single-chip microcomputer, a digital signal processor, a three-axis acceleration sensor and a temperature sensor.

[0036]The transformer vibration monitoring unit is also connected to a power source and placed in a sealed casing to form a vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com