Medium dielectric coefficient measuring probe with coaxial line structure under high-temperature condition and system

A high temperature state, dielectric coefficient technology, applied in the measurement device, measurement of electrical variables, measurement of resistance / reactance / impedance and other directions, can solve the problem of inability to use measurement, filling medium can not withstand high temperature and other issues, to achieve easy testing, preparation process The effect of simple, high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

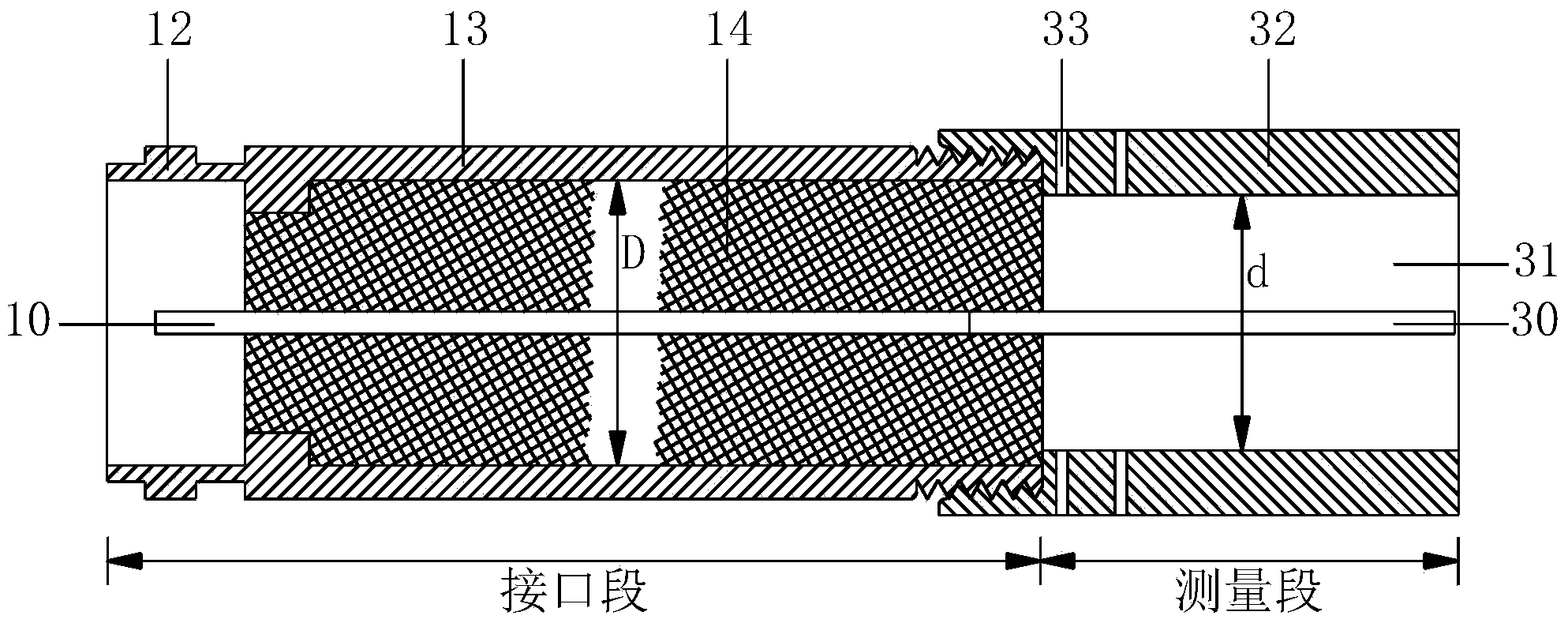

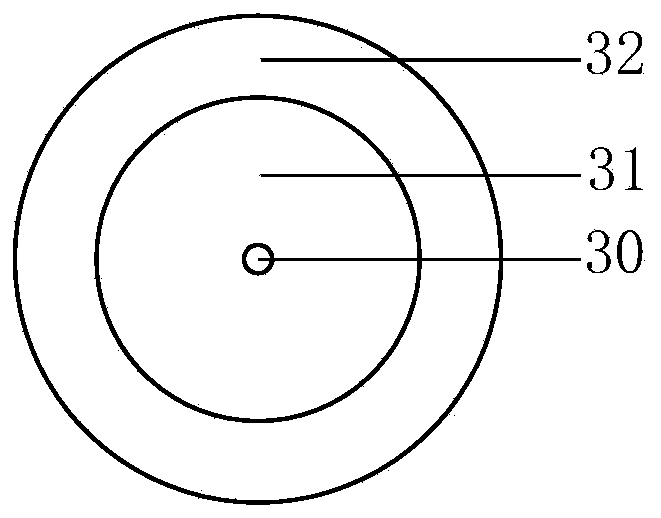

[0034] In this example, the structure of the measuring probe is as follows: figure 1 and figure 2 As shown, including the measurement section and the interface section. One end of the interface section is connected to the measurement section, and the other end is an N-type coaxial joint structure. The inner conductor 10 of the interface section and the outer conductor 13 are filled with a high-temperature-resistant and heat-insulating solid medium 14. The inner diameter of the outer conductor 32 of the measuring section is slightly smaller than the inner diameter of the outer conductor 13 of the interface section. The solid medium 14 falls off. Since the inner diameter D of the outer conductor of the interface section is not much different from the inner diameter d of the outer conductor of the measurement section, the microwave reflection caused by the boss is very low and does not affect the measurement of the dielectric constant of the medium. In this example, D-d=0.5mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com