Temperature rise test method for large transformer

A temperature rise test and transformer technology, applied in instruments, measuring electrical variables, components of electrical measuring instruments, etc., can solve the problems of high rated voltage, low load factor, low impedance voltage, etc., to achieve high accuracy, Reasonable structure and easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

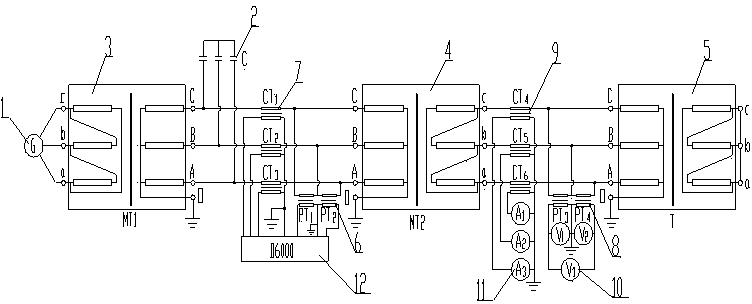

[0020] The drawings show specific embodiments of the invention. Such as figure 1 As shown, the test circuit of this large transformer temperature rise test method is connected as follows:

[0021] ⑴Firstly, connect the output terminal of the power frequency generator set 1 to the reactive power compensation capacitor 2 through the intermediate transformer 3; select the standard voltage transformer 6 for power analyzer and the standard current transformer for power analyzer based on the output voltage and current of the power supply The tap position of the power analyzer 7 is connected in series with the tap position of the standard current transformer 7 to the output terminals of the intermediate transformer 3 and the reactive power compensation capacitor 2, and then through the bus bar, isolation switch, cable and temporary intermediate transformer The high-voltage side of 4 is connected, and the tap position of the standard voltage transformer 6 for the power analyzer is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com