Demonstration-free laser three-dimensional measurement method based on reverse engineering technology and device

A reverse engineering, laser three-dimensional technology, applied in the direction of program control, instrument, computer control, etc., can solve the problems of difficult and accurate control, time-consuming and labor-intensive, and accuracy cannot be effectively guaranteed, so as to improve processing efficiency, reduce technical requirements, and save processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

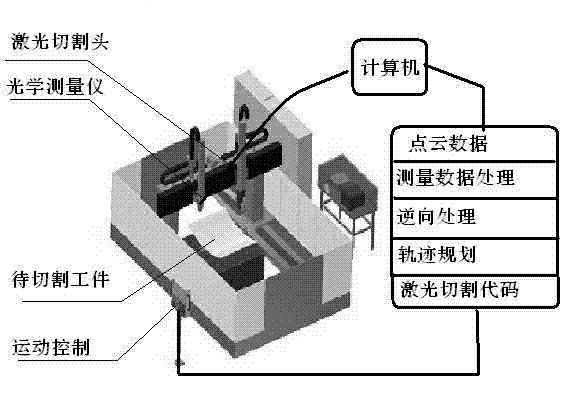

[0018] A teaching-free laser automatic cutting device based on reverse engineering technology, its composition includes: a five-axis linkage laser cutting machine, the five-axis linkage laser cutting machine is connected to digital acquisition hardware and a computer, and together constitute a three-dimensional system for obtaining point cloud data of the workpiece As for the measurement system, the optical measuring instrument of the digital acquisition hardware is fixed with the laser cutting head as a measuring device for the spatial point coordinates of the workpiece.

Embodiment 2

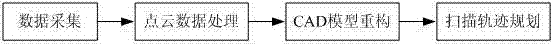

[0020] A teaching-free laser three-dimensional measurement method based on reverse engineering technology. An optical measuring instrument is fixed on the laser cutting head, and the motion control system of the cutting machine drives the optical measuring instrument to move together. The optical measuring instrument and the five-axis linkage laser cutting are used. The numerical control system of the machine constitutes an opportunity measurement system to complete the measurement of the coordinates of the workpiece space point, obtain its point cloud data, and then use the reverse engineering software to reconstruct the CAD model of the workpiece, and then realize the laser cutting attitude and trajectory according to the CAD model. Online planning.

Embodiment 3

[0022] In the teaching-free laser three-dimensional measurement method based on reverse engineering technology described in Example 2, the optical measuring instrument and the laser cutting head are fixed together, and the numerical control system of the five-axis linkage laser cutting machine is used to form an opportunity measurement system. It is completed on the same equipment, and the workpiece is measured and processed in one clamping, eliminating the error of secondary clamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com