Laser control circuit and method and laser level provided with control circuit

A technology for controlling circuits and lasers, applied in the field of laser ink line instruments, can solve problems such as damage to the laser tube, large peak interference amplitude, and monotonous function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The advantages of the present invention are further described below with reference to the accompanying drawings and specific embodiments.

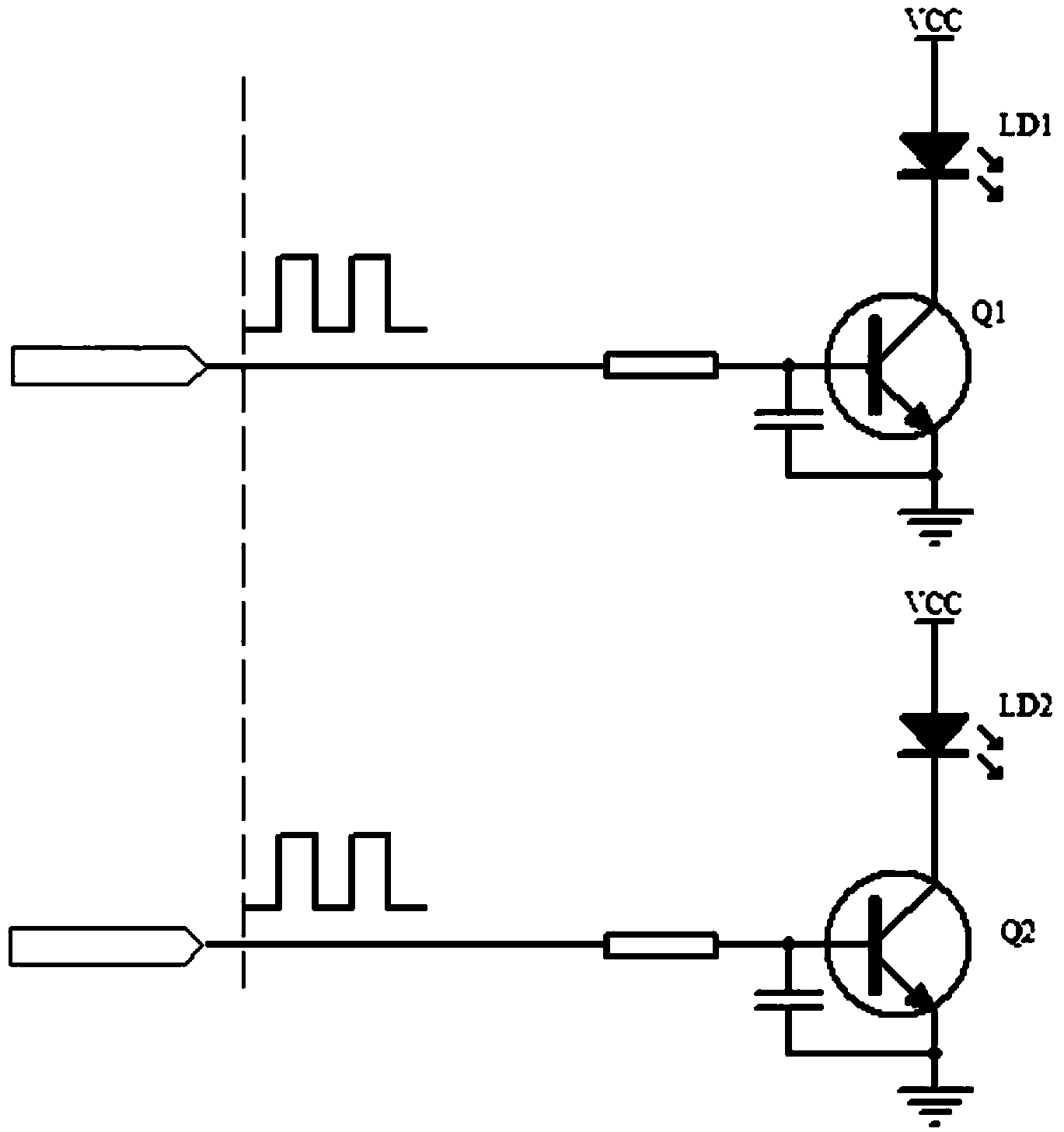

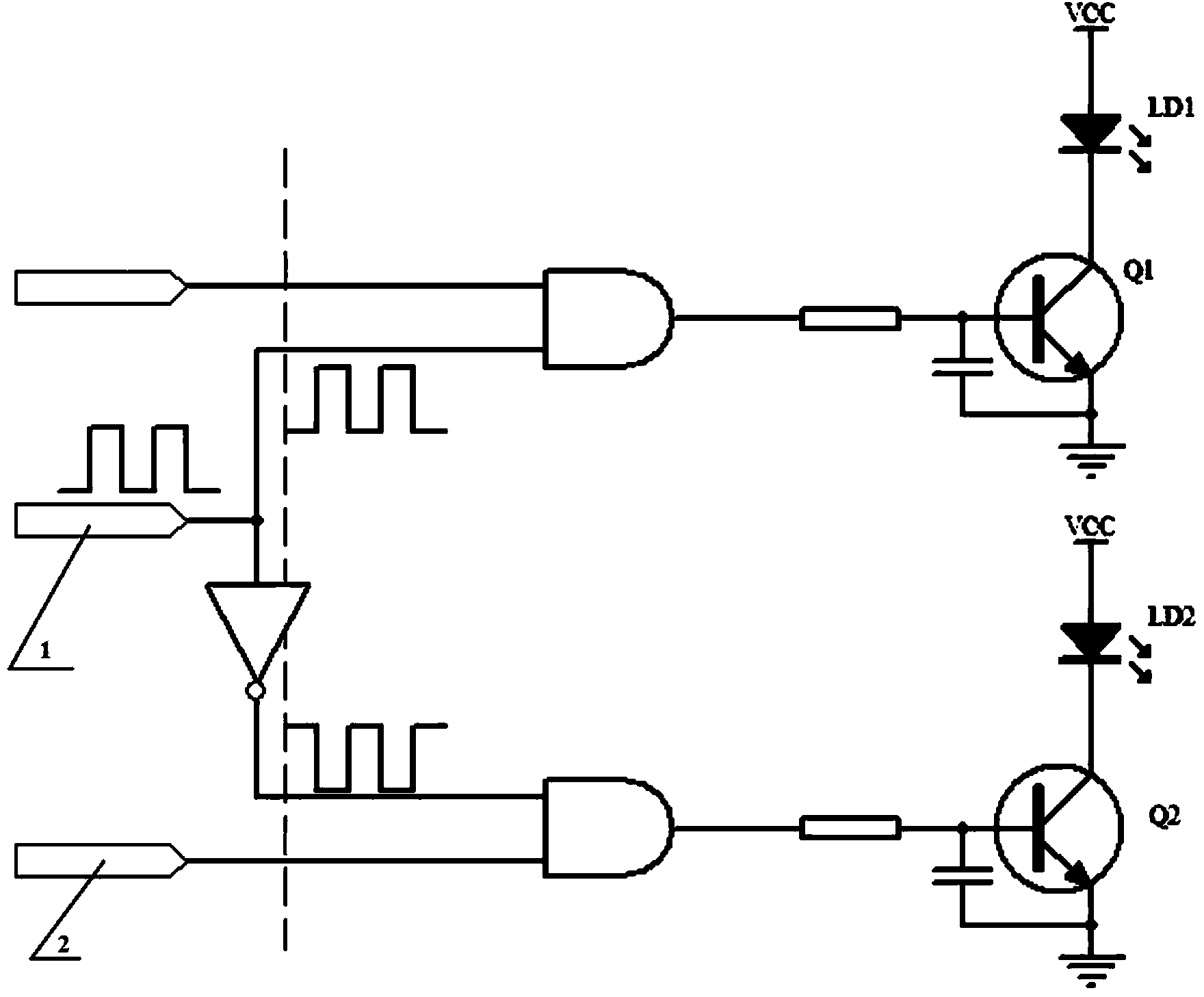

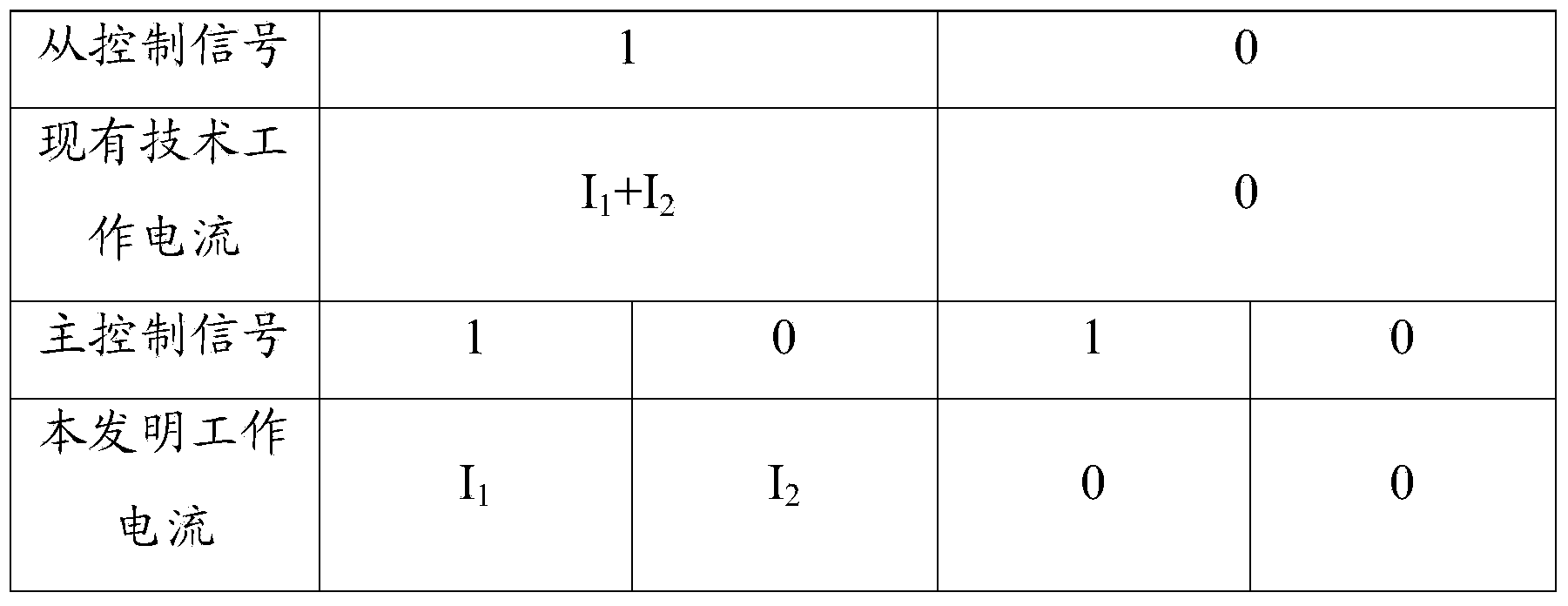

[0020] like figure 2 As shown, it is a schematic diagram of the configuration of the control circuit in a preferred embodiment of the present invention. The laser control circuit includes at least two laser tubes and a control unit for controlling the at least two laser tubes respectively, and the control unit sends a control signal to each laser tube to control the on / off state of the laser tube. In the present invention, in order to solve the above problem, at least two laser tubes are firstly divided into two groups, namely the first laser tube group and the second laser tube group. The grouping method is not limited, and the user can work according to the actual work. It is required to classify the lasers that need to display different states into the first group or the second group. For example, one laser tube is defined as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com