Device capable of reducing high-frequency rectification power supply ripple factors

A power ripple, high-frequency rectification technology, applied in the output power conversion device, electrical components and other directions, can solve the problems of decreased uniform plating ability, increased defective product rate, poor deep plating ability of the coating layer, etc., to eliminate pulse burrs, The effect of flat waveform and improved performance index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

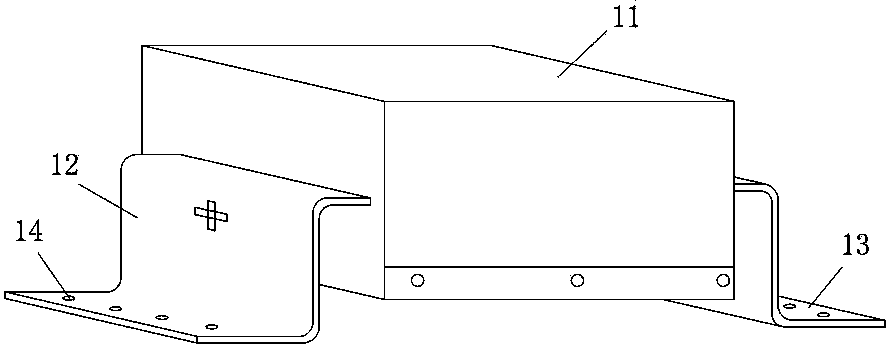

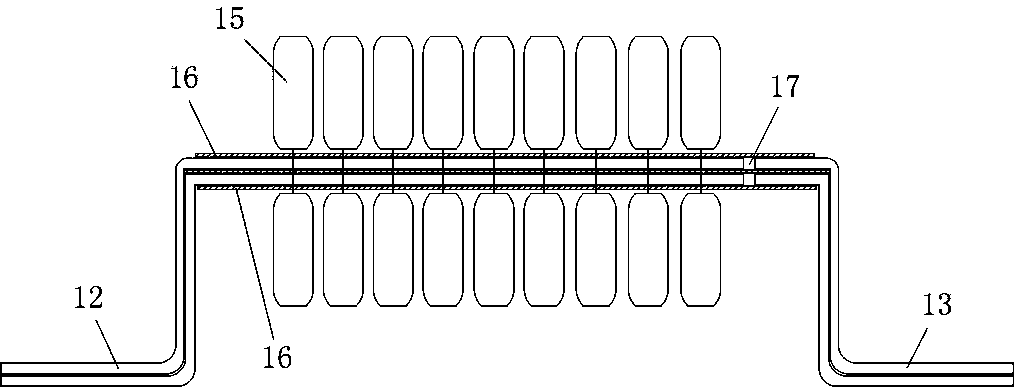

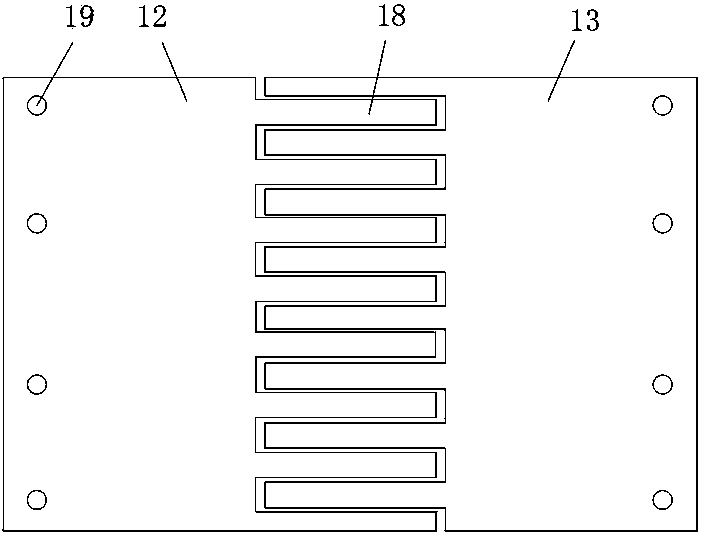

[0024] In this example, refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the device that can reduce the ripple coefficient of the high-frequency rectified power supply includes a capacitor group part 1 and an inductance group part 2, wherein the inductance group part 1 is installed at the positive electrode conductive copper bar 5 in the electroplating tank 3, and the capacitor group part 1 is connected across the Between the positive electrode copper bar 5 and the negative electrode conductive copper bar 4 in the electroplating tank 3, the inductance group part 2 is located closer to the power supply than the capacitor group part 1, and the current first passes through the inductance group part 2, then through the capacitor group part 1, and finally Then to the electroplating tank 3; the capacitor group part 1 includes a shell 11, in which a positive copper plate 12 and a negative copper plate 13 are provided, and the positive copper plate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com