Three-layer antislip bath mat

A bath mat and anti-slip technology, applied in bathtubs, showers, household appliances, etc., can solve the problems of low safety factor, poor water leakage effect, poor comfort, etc., and achieve high glass strength, good water leakage effect, and adhesion. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

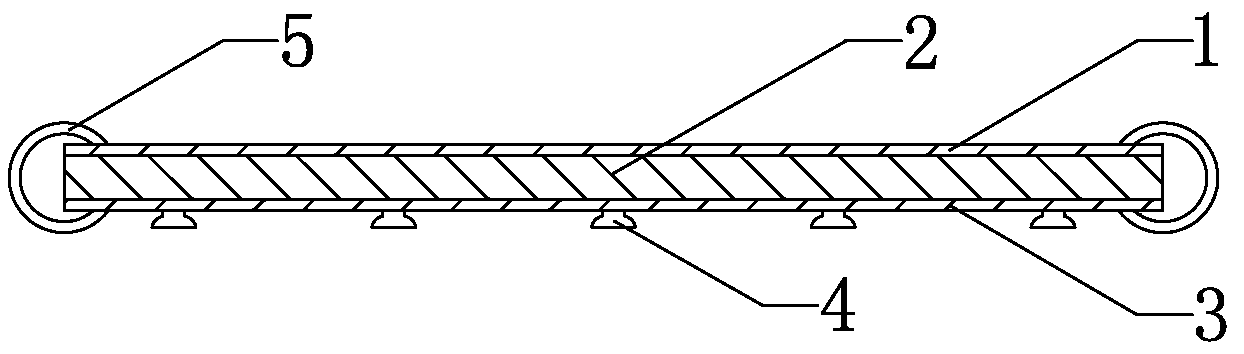

[0051] See Figure 1~3 , a three-layer anti-slip bath mat, the anti-slip bath mat is provided with a surface layer 1, a support layer 2 and a three-layer structure of the bottom layer 3, the support layer 2 is arranged between the surface layer 1 and the bottom layer 3, and the bottom of the bottom layer 3 is fixed with a plurality of Suction cup 4, hemming 5 is sewn on the outside of the non-slip bath mat, surface layer 1 and bottom layer 3 are fiber mesh cloth, and support layer 2 is fish silk mesh cloth.

[0052] In this embodiment, the thickness of the fiber mesh cloth is 1 mm, and the thickness of the fish silk mesh cloth is 6 mm.

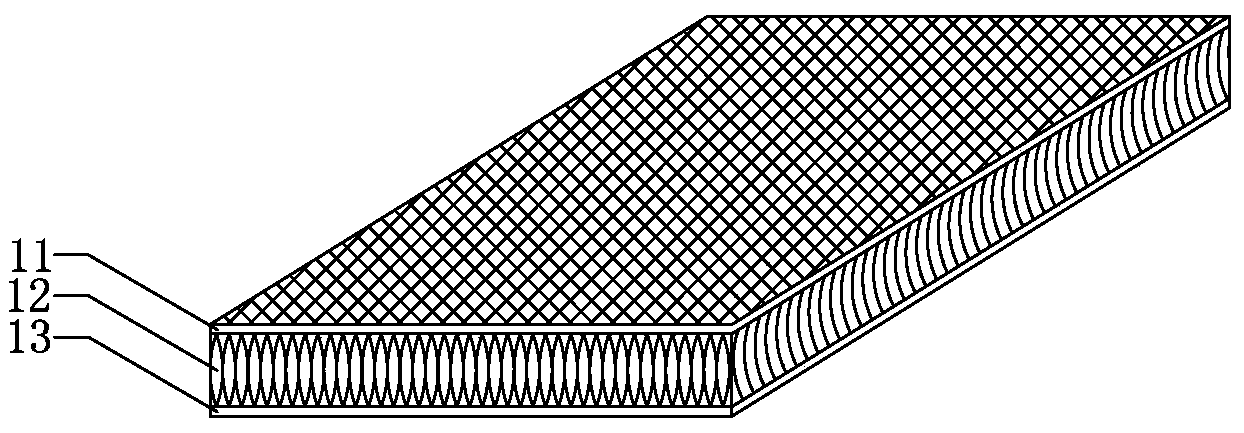

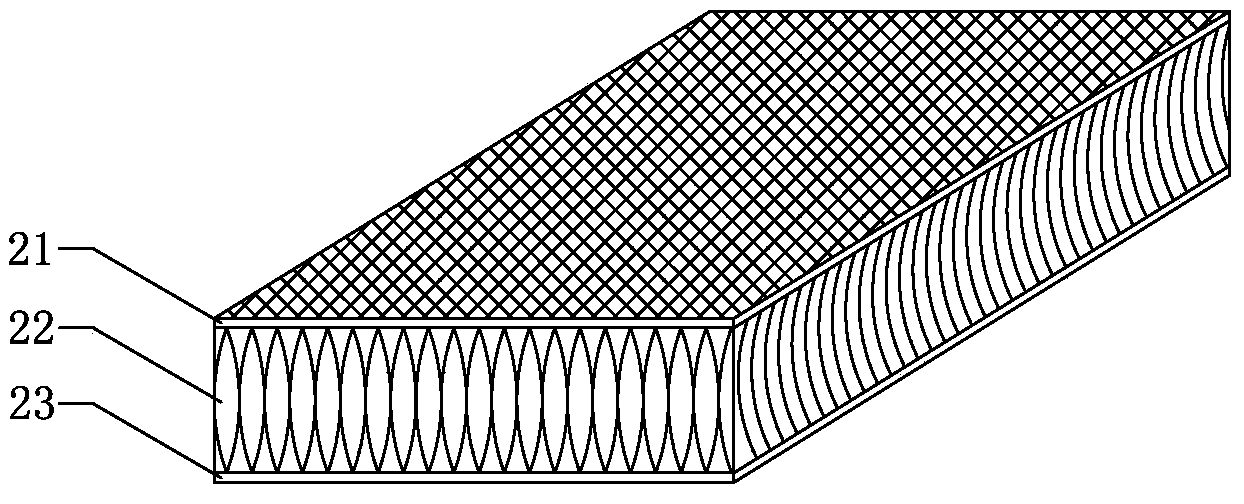

[0053] In this embodiment, the fiber mesh cloth is provided with a three-layer structure of an outer layer 11, an interlayer 12 and an inner layer 13, the interlayer 12 is arranged between the outer layer 11 and the inner layer 13, and the outer layer 11 and the inner layer 13 are all made of polyester single layer. Silk warp knitting, the th...

Embodiment 2

[0069] The difference between this embodiment and the above-mentioned embodiment 1 lies in that the thickness of the fiber mesh cloth is 2 mm, and the thickness of the fish silk mesh cloth is 7 mm.

[0070] In this embodiment, the fiber mesh cloth is provided with a three-layer structure of an outer layer 11, an interlayer 12 and an inner layer 13, the interlayer 12 is arranged between the outer layer 11 and the inner layer 13, and the outer layer 11 and the inner layer 13 are all made of polyester single layer. Silk warp knitting, the thickness of the outer layer 11 and the inner layer 13 is 0.2mm, interlayer 12 is woven by nylon monofilament and forms X cross structure or mutual parallel structure or IXI alternate structure, the thickness of interlayer 12 is 1.6mm, The outer layer 11, the interlayer 12 and the inner layer 13 are integrally knitted into a fiber mesh cloth.

[0071] In this embodiment, the woven fiber mesh is treated with a dipping solution, and the dipping so...

Embodiment 3

[0086] The difference between this embodiment and the above-mentioned embodiment 1 lies in that the thickness of the fiber mesh cloth is 2 mm, and the thickness of the fish silk mesh cloth is 8 mm.

[0087] In this embodiment, the fiber mesh cloth is provided with a three-layer structure of an outer layer 11, an interlayer 12 and an inner layer 13, the interlayer 12 is arranged between the outer layer 11 and the inner layer 13, and the outer layer 11 and the inner layer 13 are all made of polyester single layer. Silk warp knitting, the thickness of the outer layer 11 and the inner layer 13 is 0.2mm, interlayer 12 is woven by nylon monofilament and forms X cross structure or mutual parallel structure or IXI alternate structure, the thickness of interlayer 12 is 1.6mm, The outer layer 11, the interlayer 12 and the inner layer 13 are integrally knitted into a fiber mesh cloth.

[0088] In this embodiment, the woven fiber mesh is treated with a dipping solution, and the dipping so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com