A grinding method and device for thermoplastics

A technology of thermoplastics and grinding methods, which is applied in the direction of grain processing, etc., which can solve the problems of affecting the quality of plastics, failure to grind, high temperature, etc., and achieve the effect of preventing sticking and ensuring change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

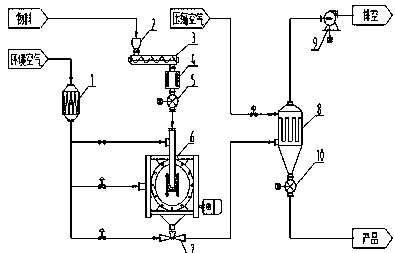

[0029] The equipment that the present invention adopts except grinder 6, other equipments: air filter 1, feeding buffer bin 2, screw conveyor 3, electromagnetic separator 4, rotary unloader 5, Venturi conveyor 7, bag filter 8 , induced draft fan 9, and rotary unloader 10 are conventional equipment, which can be used in conjunction with standard selection and process.

[0030] Attached below figure 1 , the process flow of a grinding method for thermoplastics is described as follows:

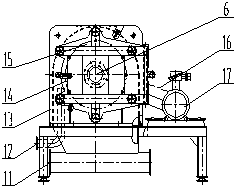

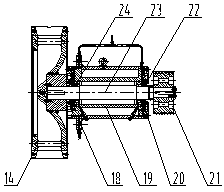

[0031] After drying, the plastic powder that needs to be ground at a temperature of ~60°C enters the feeding buffer bin 2, and is transported to the electromagnetic separator 4 by the screw conveyor 3 to prevent the iron filings in the plastic powder from damaging the grinder 6. After iron filings are removed, it enters the rotary unloader 5 and sends the plastic powder into the rotor cavity of the grinder 6 continuously and evenly. Grinder 6 is mainly composed of transmission system, housing 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com