Automatic small regular workpiece feeding device for numerically controlled milling machine

A technology of automatic feeding and CNC milling machine, which is applied in metal processing and other fields, and can solve problems such as longer processing time, increased product cost, and unfavorable market competition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

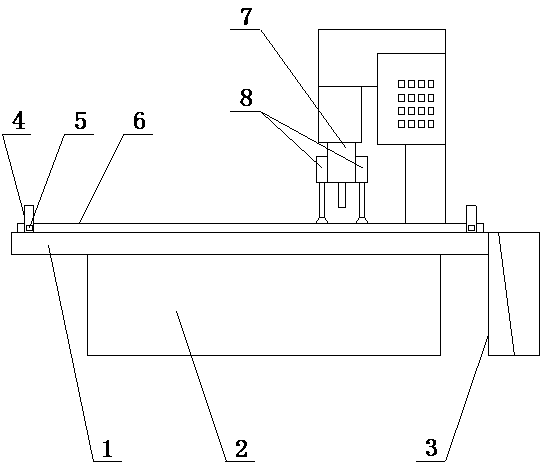

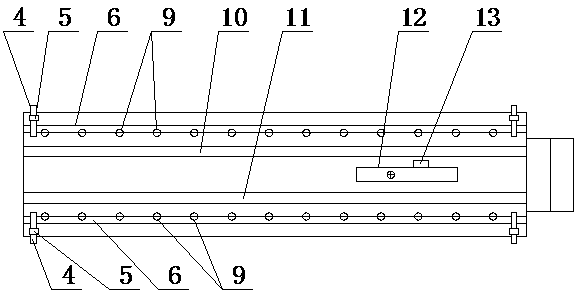

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] Such as figure 1 , figure 2 As shown, a kind of automatic feeding device for CNC milling machine with small regular workpieces according to the present invention includes an automatic feeding device body, and the automatic feeding device body includes a support rod 5 arranged at the four corners of the workbench 1, The four support rods 5 are movable respectively with connecting rods 4; a horizontal baffle 6 is respectively pierced between the two connecting rods 4 on the same side of the workbench 1; The horizontal belt A10 and the horizontal belt B11 parallel to each other; a strip-shaped groove 12 is arranged on the right side of the workbench 1, and an induction contact switch 13 is arranged on the right side of the strip-shaped groove 12; the workbench 1 A telescopic cylinder 8 is respectively arranged on the left and right sides of the knife rest 7 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com