A fully automatic strong cooling single-arm stone multi-piece processing combined circular sawing machine

A circular sawing machine and strong cooling technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of affecting tool life, large starting current, energy waste, etc., to reduce additional energy consumption and improve work efficiency , Fragmentation quality is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

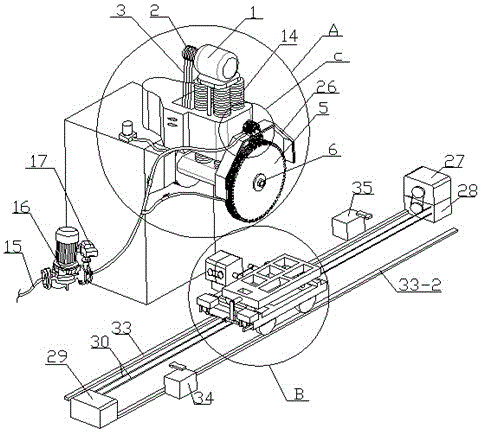

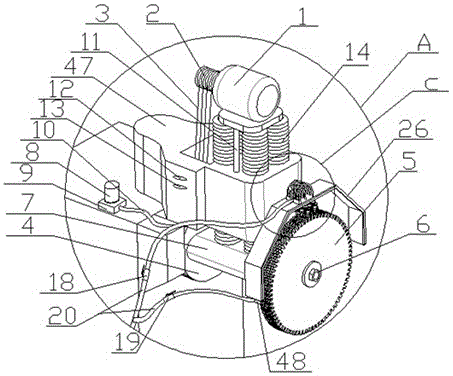

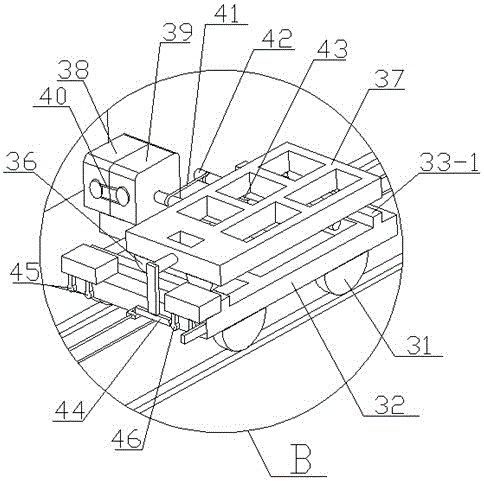

[0019] The present invention is a fully automatic strong cooling single-arm stone multi-piece processing combined circular sawing machine, which includes a hydraulic mechanism that automatically lowers and raises the spindle box to realize tool feeding and retracting, and a hydraulic mechanism that automatically adjusts the position of the stone material to realize non-stop operation. The displacement feeding mechanism that can realize continuous cutting of the same piece of stone is characterized in that: a strong cooling and flushing mechanism, the strong cooling and flushing mechanism has a booster pump 16, and an electric switch valve 17 connected with the booster pump 16 , the electric on-off valve 17 is connected with the water pressure gauge 21 and the diverter water tank 22 in turn through the high-pressure pipe I20, the electric on-off valve 17 is connected with the horizontal spray pipe 48 through the high-pressure pipe I20, and the electric on-off valve 17 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com