Safeguard system of rubber wheel vehicle

A technology for safety protection and rubber-tyred vehicles, which is applied in the field of safety protection systems for mining vehicles, can solve problems such as brake oil pollution, increase the inertia of vehicle motion, and failure to shift gears, so as to reduce casualties and achieve good real-time control performance , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

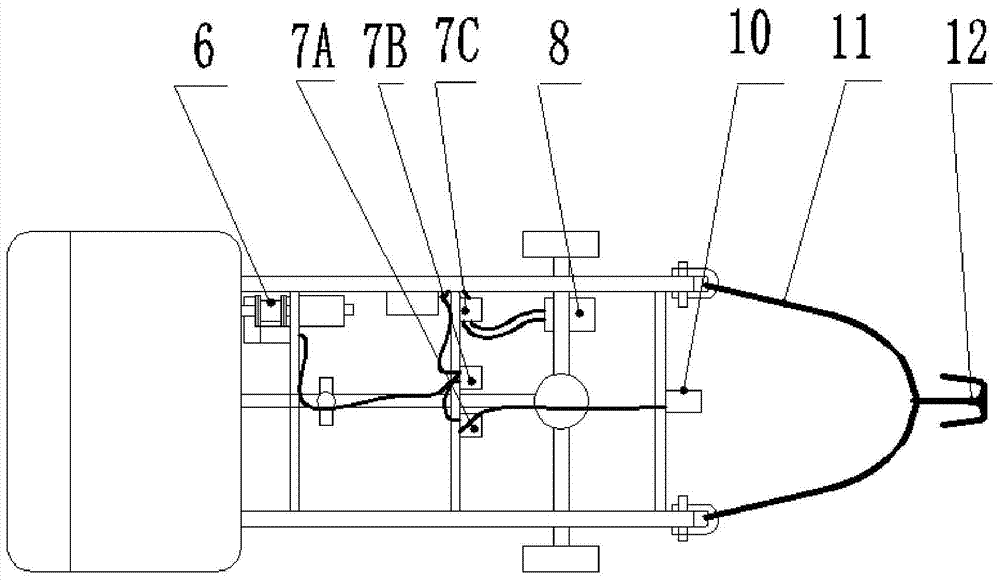

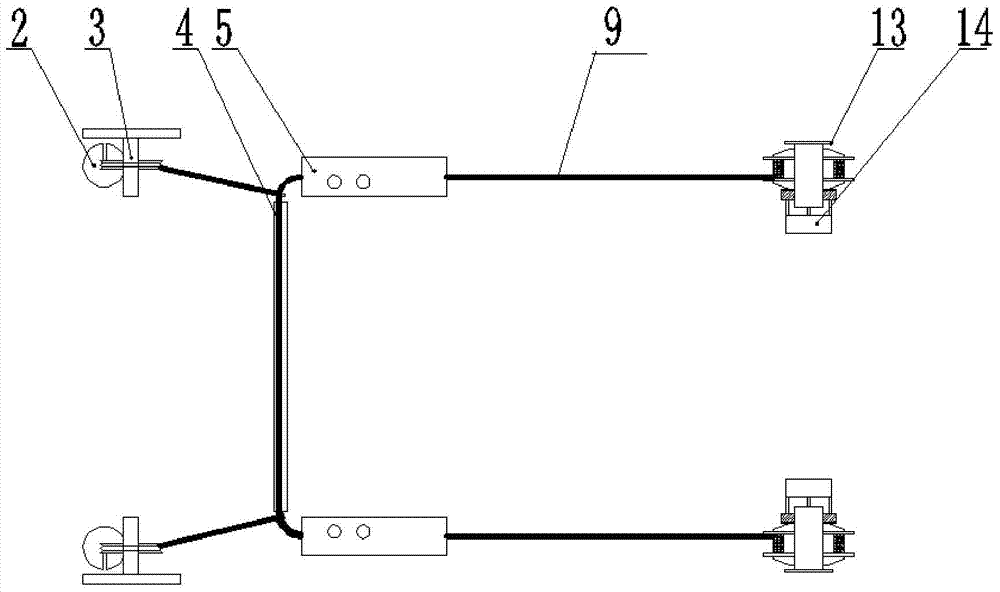

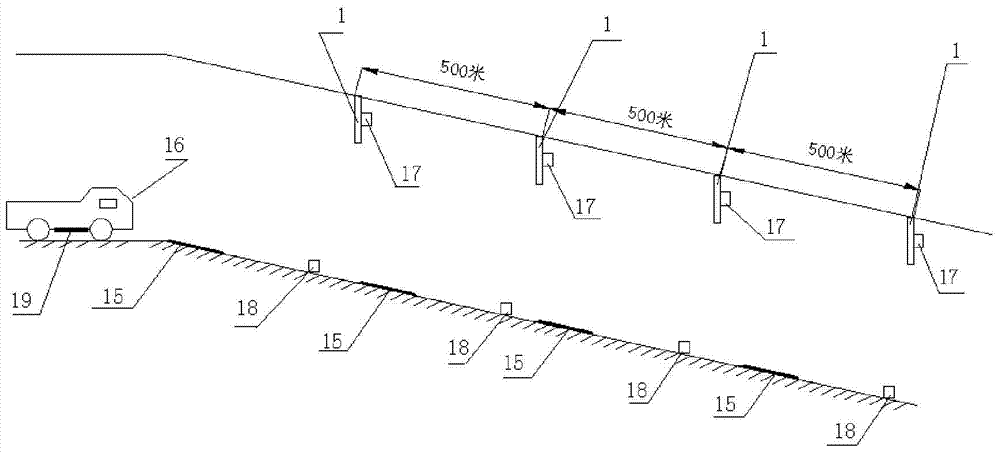

[0024] Such as figure 1 and figure 2 As shown, the exhaust brake (6) is installed on the exhaust pipe of the vehicle, and fixed on the longitudinal beam of the vehicle with a fixed frame, and the disc of the exhaust brake (6) is released by the air cylinder installed on the fixed frame. Control its opening and closing, the air circuit control valve (7B) controls the expansion and contraction of the pneumatic cylinder, and the vehicle-mounted ECU controls the air circuit control valve; connect the air circuit control valve (7A), the air circuit control valve (7B), and the air circuit control valve (7C) and the corresponding pipelines are fixed on the vehicle crossbeam; connect the steel wire rope I (11) to the vehicle through a U-shaped clip on the longitudinal beam of the vehicle, and the anchor hook (12) is passed on the steel wire rope I (11), and the steel wire rope Ⅰ (11) is mounted on the rear end of the vehicle. During normal operation, the anchor hook (12) is locked o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com