A kind of calcined zinc oxide production process

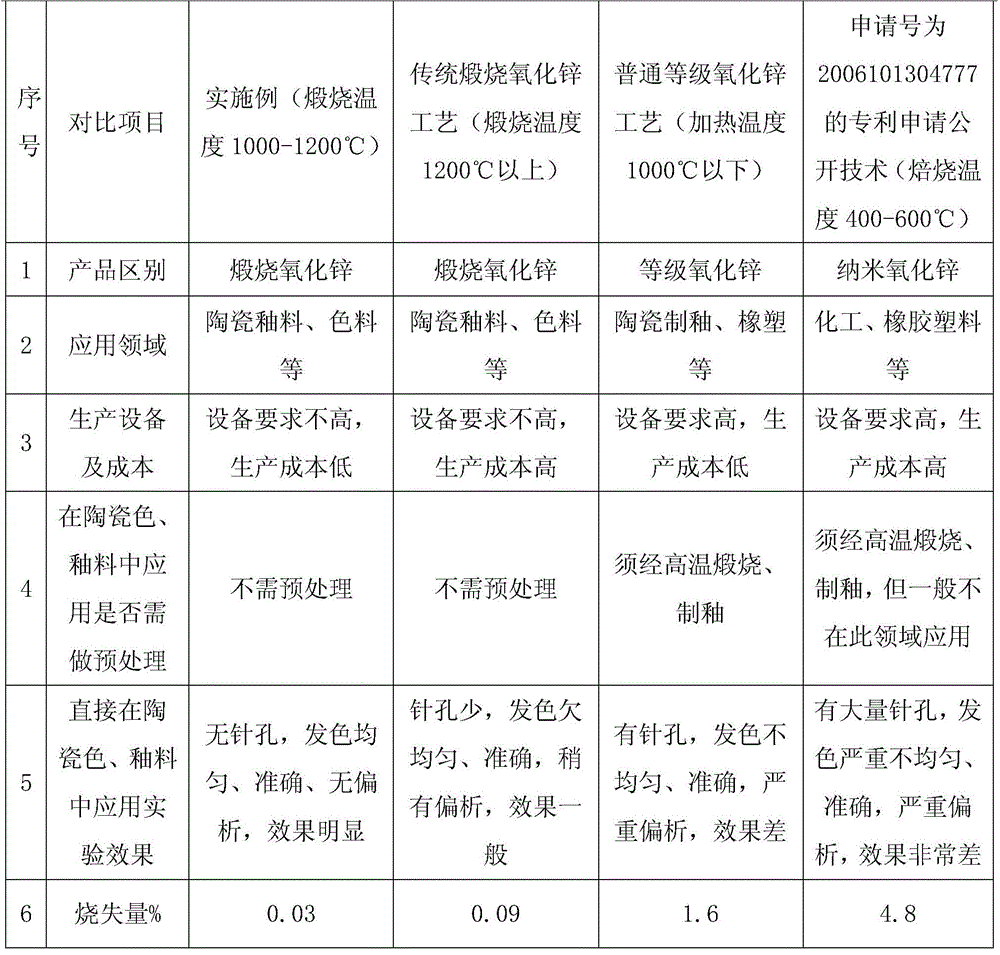

A technology for calcining zinc oxide and production process, applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of high product price, high production cost, high energy consumption, and achieve increased gloss and whiteness, low production cost, and reaction conditions. mild and friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] A production process for calcined zinc oxide, which comprises the following steps:

[0028] 1) Leaching: Using ammonia water and ammonium bicarbonate as the leaching solvent, the zinc in the secondary zinc oxide is leached to make a zinc ammonia complex solution; the main reaction formula of this step is as follows:

[0029] ZnO+3NH 3 ·H 2 O+NH 4 HCO 3 =Zn(NH 3 ) 4 CO 3 +4H 2 o

[0030] Specifically, the leaching is a two-stage type, which is carried out in two leaching tanks respectively. The filter residue after the first stage leaching is added to the second stage leaching tank under stirring and then leached, and the filter residue leached in the second stage is discarded. The secondary immersion solution from the second stage leaching is added to the first stage leaching tank as a leaching solvent, and the secondary zinc oxide is put into the first leaching tank under stirring, and the leaching primary immersion solution enters the next step, and so on. Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com