Curved surface laser beam heat treatment device and method for controlling position of laser spot

A technology of laser heat treatment and curved surface, applied in the field of laser heat treatment, to achieve the effect of sensitive motion, improve accuracy and sensitivity, and realize real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

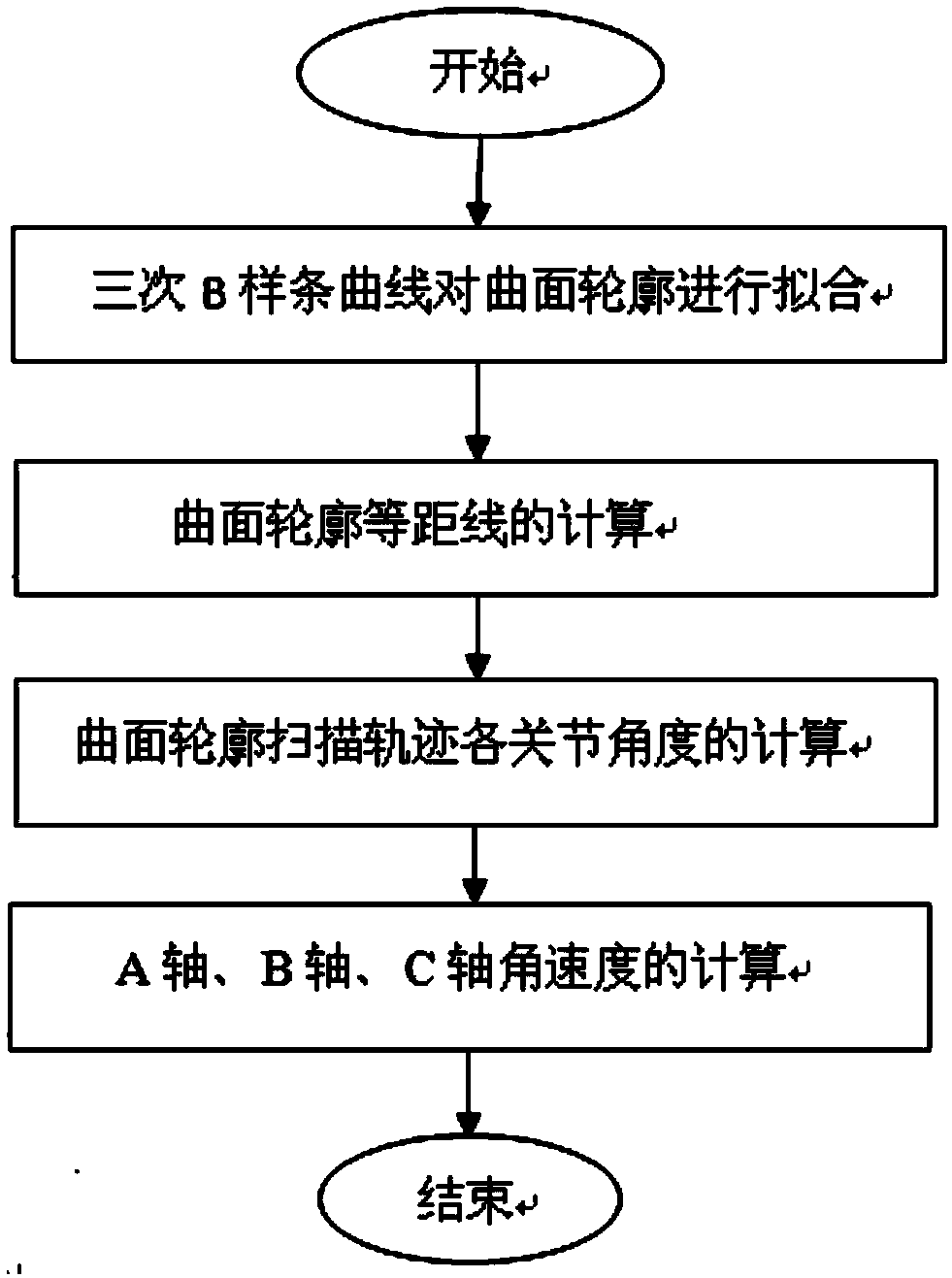

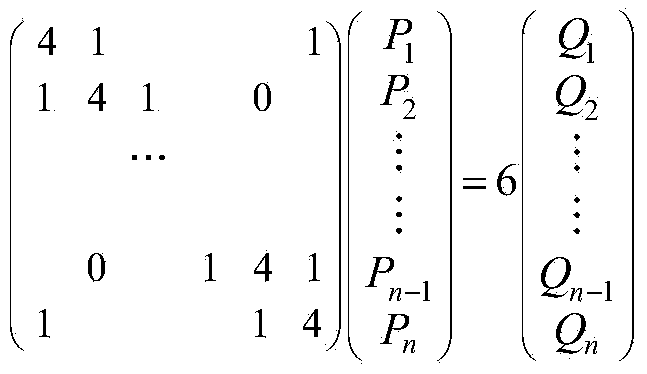

Method used

Image

Examples

Embodiment Construction

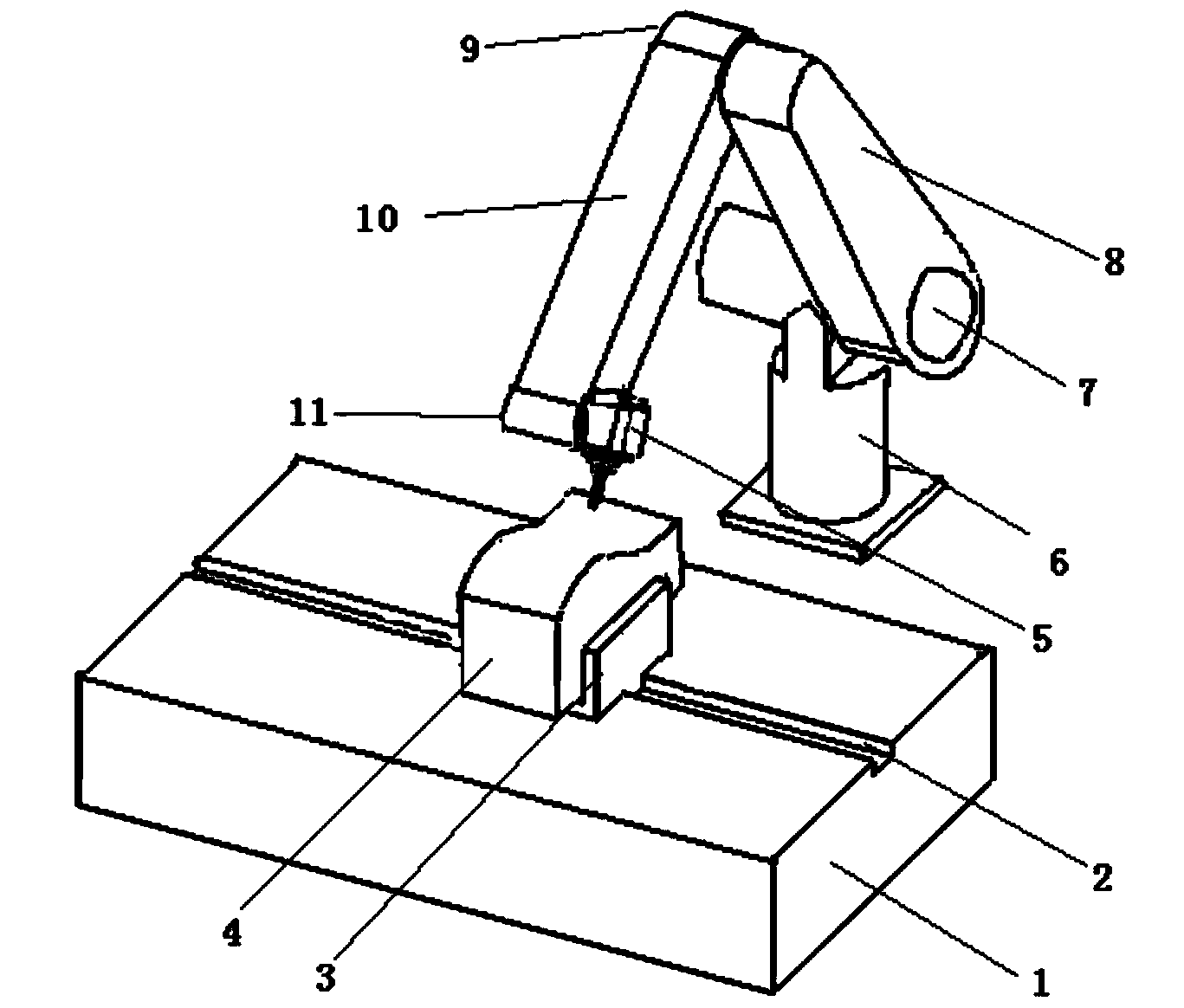

[0014] In order to realize the quenching of the laser on the curved surface, the present invention provides a laser heat treatment device, which includes a machine tool main body installed on the worktable 1, a laser device 5 installed on the machine tool main body, and a servo drive device for driving the movement of each rotating axis of the machine tool main body. , a computer numerical control system for controlling the servo drive device; the machine tool main body includes a base 6, an A rotating shaft 7 installed on the base, a first rotating arm 8 and a second rotating arm 10, one end of the first rotating arm 8 and the A rotating shaft 7 Connected, the other end is connected with one end of the second rotating arm 10 through the B rotating shaft 9, the other end of the second rotating arm 10 is connected with the laser emitting device 5 through the C rotating axis 11, and the laser emitting device 5 is kept perpendicular to the surface of the workpiece 4 The worktable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com