Novel vertical needle

A new type of vertical needle technology, used in textiles, textiles, papermaking, jacquard machines, etc., can solve the problems of low reliability, troublesome disassembly and assembly of vertical needles, short service life, etc., achieve sensitive movement, solve easy deformation, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

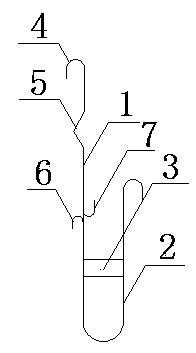

[0010] Such as figure 1 It is a schematic diagram of the structure of the present invention, a new type of vertical needle, including a long needle bar 1, a short needle bar 2, a fixed piece 3, a curved hook 4, a convex turn 5, a needle stop hook 6 and an off-thread hook 7, and the long needle bar 1 A fixed piece 3 is arranged between the short needle bar 2, a curved hook 4 is provided at the top of the long needle bar 1 and the short needle bar 2, and a protruding turn 5 is arranged below the crotch 4 of the long needle bar 1, and the upper part of the long needle bar 1 Needle-stop hook 6 and thread-off hook 7 are provided.

[0011] During use, a fixed piece 3 is installed between the long needle bar 1 and the short needle bar 2, and the tops of the long needle bar 1 and the short needle bar 2 are provided with a crotch 4, and there is a convex turn 5 below the crotch 4 of the long needle bar 1. , On the long needle bar 1 below the protruding turn 5, a needle stop hook 6 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com