Tempering heat treatment process of high-strength steel

A high-strength steel, high-temperature tempering technology, applied in the field of tempering heat treatment process, can solve the problems of unreachable low-temperature impact, difficulty in balancing strength and toughness, poor repeatability and reproducibility of low-temperature impact toughness, etc. High and low temperature impact toughness, excellent comprehensive mechanical properties at room temperature, and the effect of improving comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

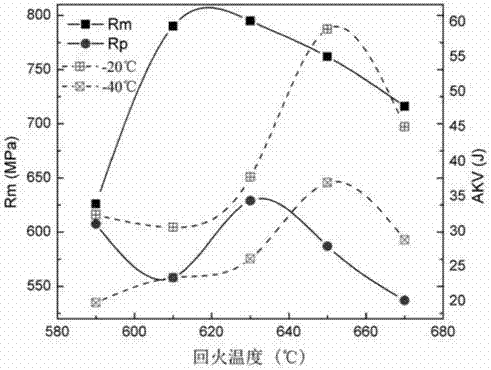

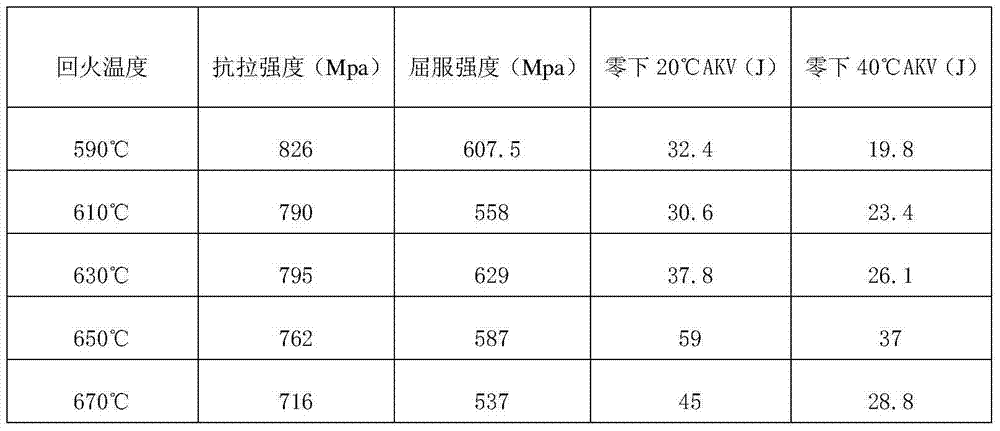

[0020] A tempering heat treatment process for high-strength steel. The process includes the following steps: a. Heating the material to 850°C to 920°C to austenitize it, and after holding it for 3 to 5 hours, cool it to room temperature and anneal it in a furnace to achieve uniform structure b. Heating the material to 850°C-920°C for austenitization, and then water quenching to 200°C-260°C after holding for 3-5 hours; After heat preservation at 630°C, 650°C, and 670°C for 2 to 5 hours, high temperature tempering is carried out. This method achieves the high strength and low temperature impact performance requirements of the material through "annealing + quenching water cooling + high temperature tempering air cooling". The chemical composition of the material is C%: 0.25-0.32, Si%: 0.60-0.90, Mn%: 0.90-1.10, P%≤0.04, S%≤0.045, Cr%: 0.40-0.80, Mo%: 0.15- 0.35, Ni%: 0.4-0.8. The phase transition temperature of the material is 841°C for AC3 and 726°C for AC1. The best temperin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com