Guardrail device synchronously opened and closed along with cover plate of hoisting hole

A technology of hanging object holes and synchronous start, which is applied in the field of floor hanging object holes, can solve the problems of taking a long time and labor, and achieve the effects of reducing labor and time, reducing quantity, and saving design and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

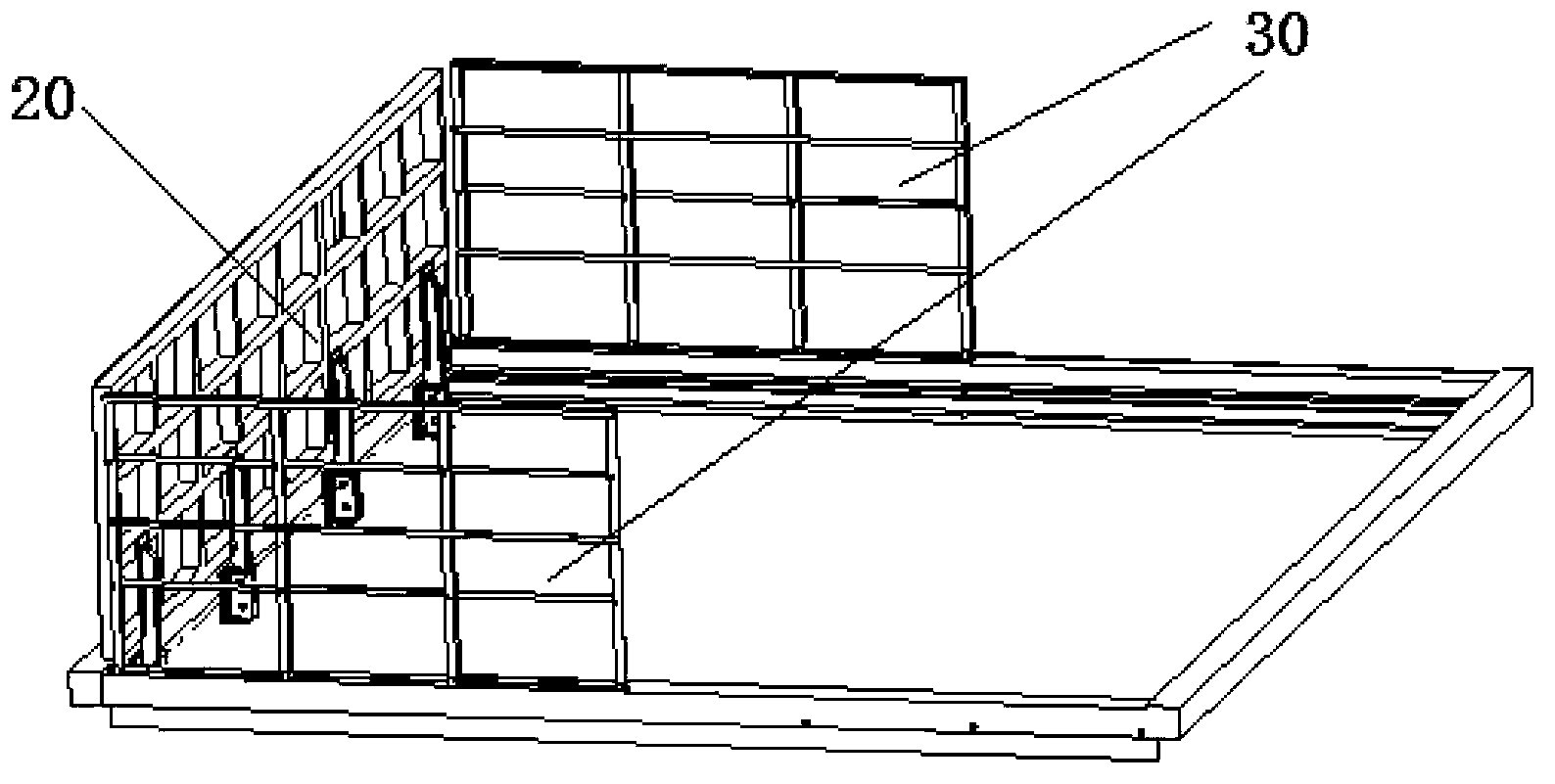

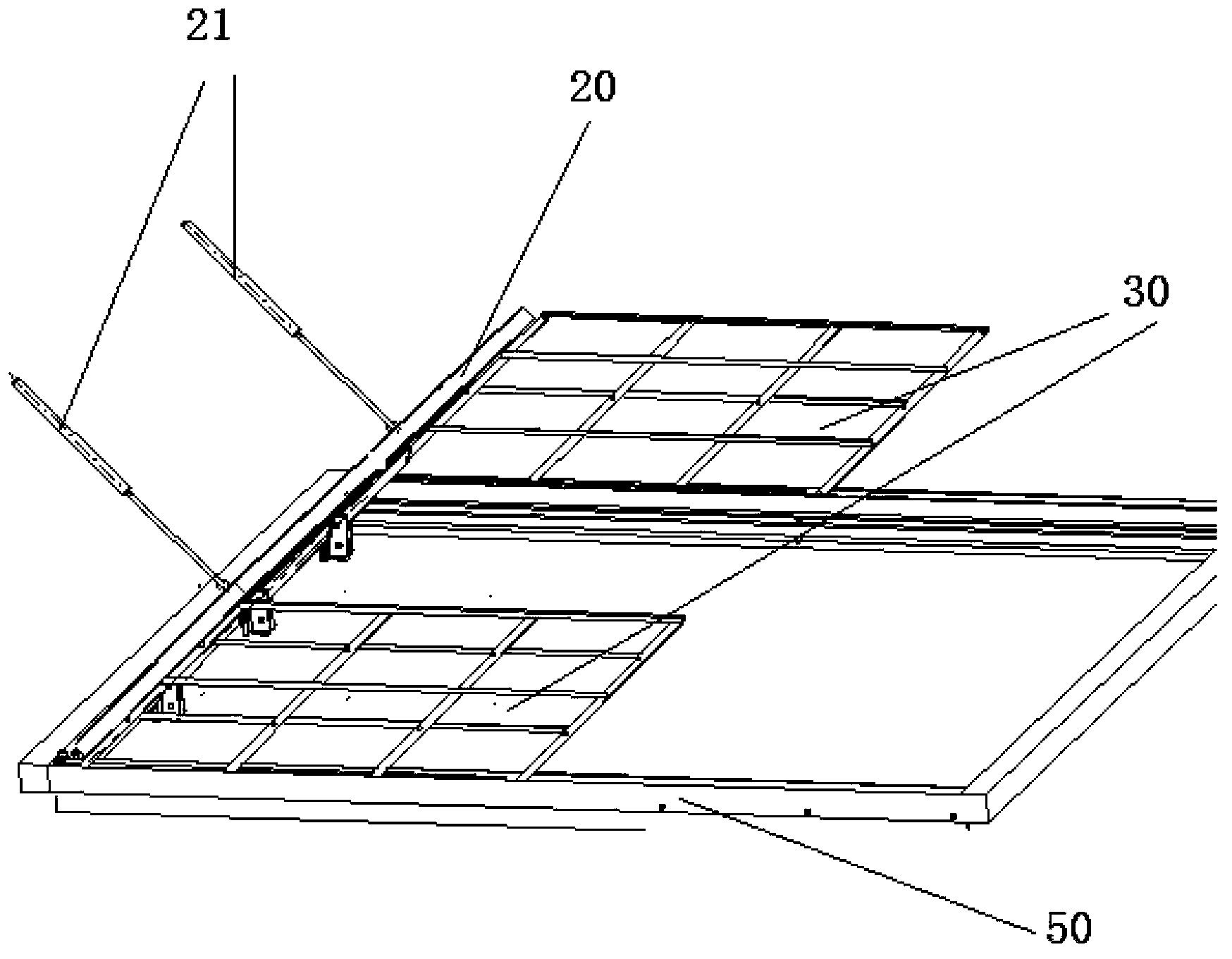

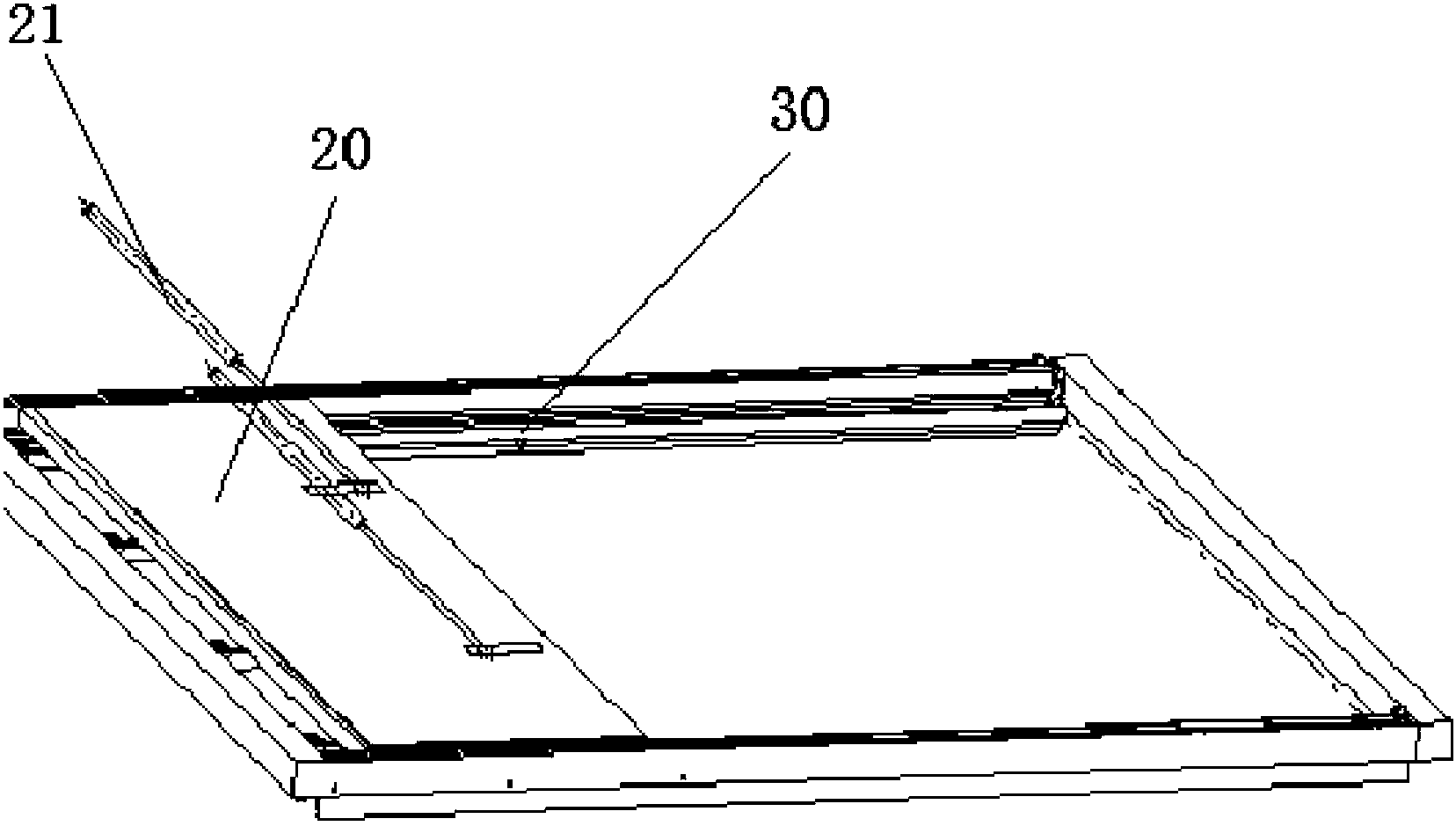

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings. see Figure 1 to Figure 9 .

[0032] like Figure 1 to Figure 3 As shown, a hanging object opening and closing simultaneously with a cover plate and a guardrail includes a cover plate 20 and a guardrail 30 . The cover plate 20 and the guardrail 30 are opened to form a fence around the object hanging hole, and the cover plate 20 and the guardrail 30 are connected in a linkage manner.

[0033] Described guardrail 30 is made up of several modules 300, as Figure 4 As shown, each module 300 includes a base 31 , several columns 32 and several beams 33 . The bottom of each column 32 is pivotally connected to the base 31 , that is, the column 32 can rotate around the base 31 , and the beam 33 and the column 32 are cross-connected to form the main body of the guardrail module 300 . Column 32 plays a main supporting role, prevents guardrail 30 from toppling along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com