Fracture sliding sleeve component

A technology for fracturing sliding sleeves and sliding sleeves, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problems of high pressure resistance performance of sliding sleeve materials, increased operation cycle and operating cost, and processing of sliding sleeves. High precision requirements and other issues, to achieve the effect of shortening the operation cycle, simple and convenient construction operation, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing.

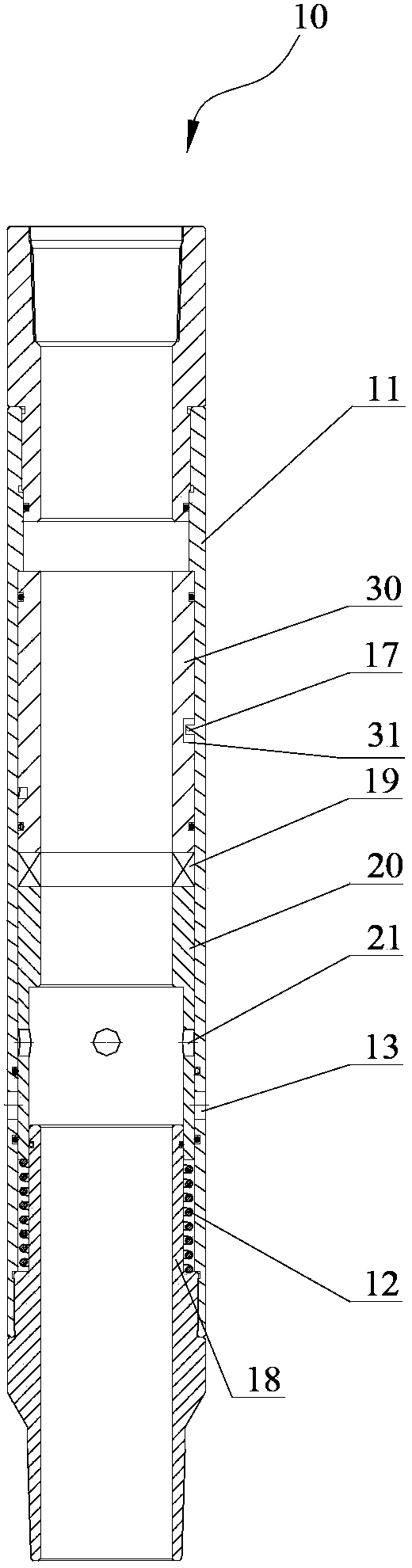

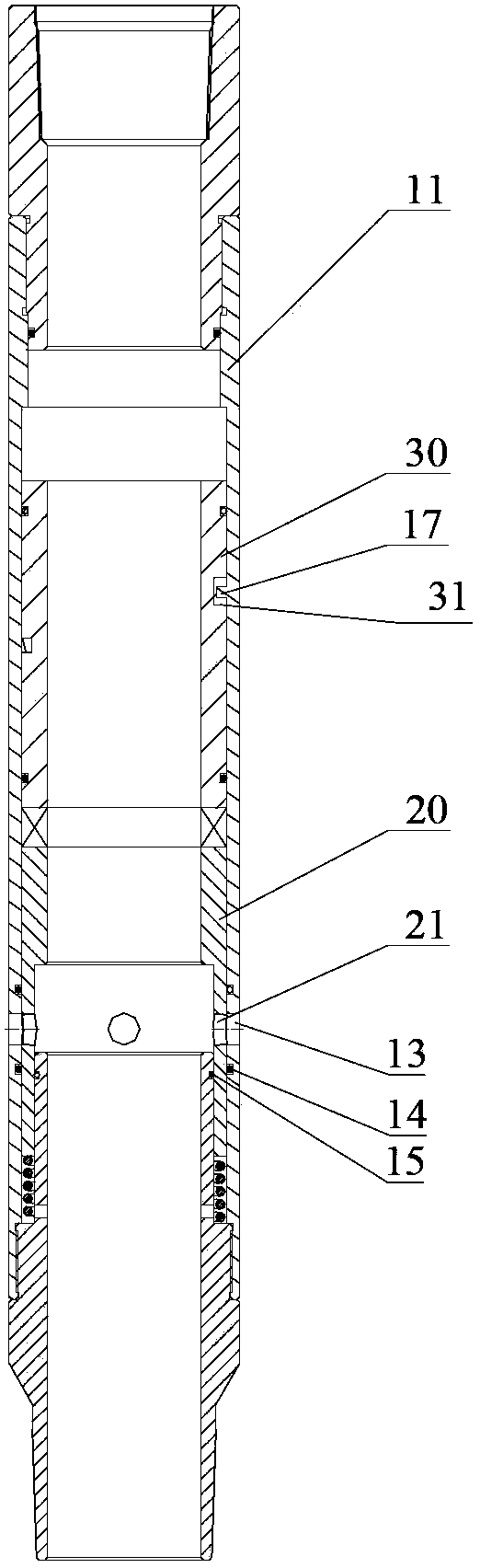

[0034] figure 1 A frac sleeve assembly 10 according to the present invention is shown schematically. The fracturing sliding sleeve assembly 10 includes a housing 11 and a first sliding sleeve 30 and a second sliding sleeve 20 installed inside the housing 11 . The first sliding sleeve 30 is located upstream of the second sliding sleeve 20 , and a bearing 19 is arranged between the first sliding sleeve 30 and the second sliding sleeve 20 . The bearing 19 can only transmit the axial movement of the first sliding sleeve 30 to the second sliding sleeve 20, but cannot transmit the rotation of the first sliding sleeve 30 to the second sliding sleeve 20. This bearing 19 is known to those skilled in the art. Well-known, for the sake of brevity, will not repeat them here.

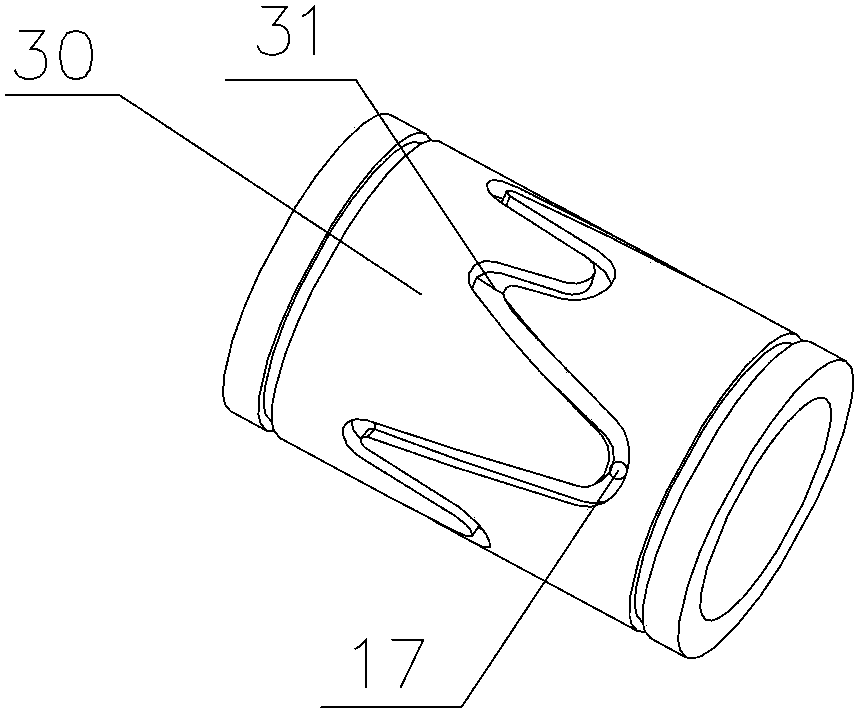

[0035] A cylindrical guide rod 17 protruding radially inward is fixedly arranged on the upstream part of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com