Wind turbine generator tower

A technology for wind turbines and machine towers, which is applied to wind turbine components, wind engines, and wind power generation. It can solve the problems of short service life of concrete structure design, high direct and indirect costs, and low life-cycle costs. Achieve the effect of avoiding the difficulty of high-altitude concrete construction, saving the amount of concrete, and clear force form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

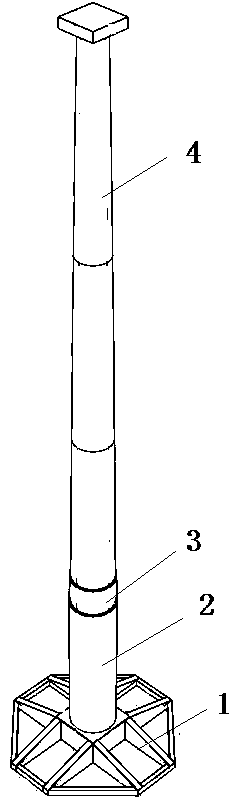

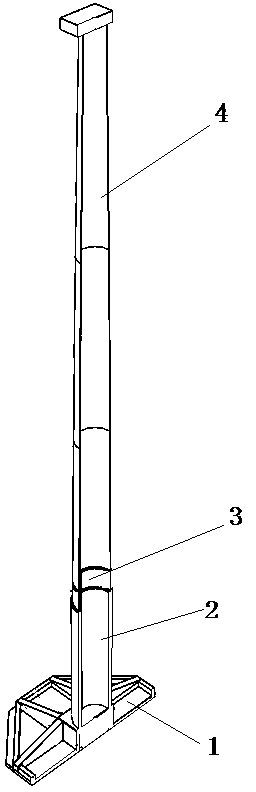

[0036] like figure 1 As shown, a wind power generator tower includes a concrete beam-slab foundation 1, a concrete bottom section tower tube 2, a steel transition tower section 3, and a steel tower section 4 from bottom to top. The concrete beam-slab foundation 1 and the prestressed concrete bottom section tower tube 2 are poured in sections using cast-in-place concrete to form a whole.

[0037] like figure 2 As shown, the concrete bottom section tower tube 2, the steel transition tower section 3, and the steel tower section 4 are all in the shape of hollow cylinders.

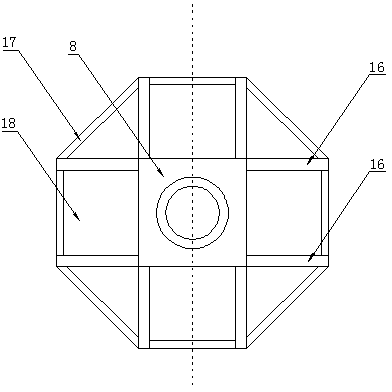

[0038] like image 3 As shown, the concrete beam slab foundation includes a base plate 18, a circular ring wall 8 located at the center of the top surface of the base plate 18, a side beam 17 arranged longitudinally on the outer edge of the base plate, a crossbeam 16 connecting the side beam 17 and the ring wall 8; The central axis of the wall 8 coincides with the vertical centerline of the tower tube 2 at ...

Embodiment 2

[0045] like Figure 9 , Figure 10 As shown, a wind power generator tower includes a concrete beam-slab foundation 1, a concrete bottom section tower tube 2, a steel transition tower section 3, and a steel tower section 4 from bottom to top. The concrete beam-slab foundation 1 and the prestressed concrete bottom section tower tube 2 are poured in sections using cast-in-place concrete to form a whole.

[0046] like Figure 11 , Figure 12 As shown, the concrete beam slab foundation includes a base plate 18, a circular ring wall 8 located at the center of the top surface of the base plate 18, a side beam 17 arranged longitudinally on the outer edge of the base plate, a crossbeam 16 connecting the side beam 17 and the ring wall 8; The central axis of the wall 8 coincides with the vertical centerline of the tower tube 2 at the concrete bottom section;

[0047] All the other structures are consistent with those of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com