Loosening-preventing and automatic-fastening device of connection bolts for combination and fixation of storage batteries

A fixed bolt and self-tightening technology, which is applied to threaded fasteners, battery pack components, bolts, etc., can solve the problems of increasing environmental pollution control costs, increasing network operating costs, and heat accumulation at connecting parts, and achieves reduction in advance The effect of scrapping phenomenon, eliminating poor contact, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

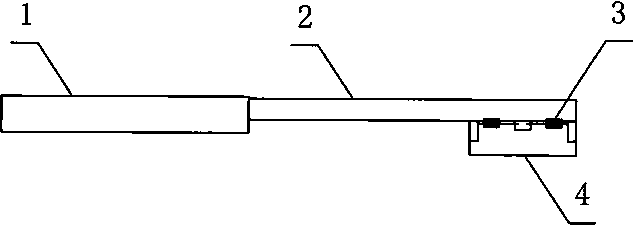

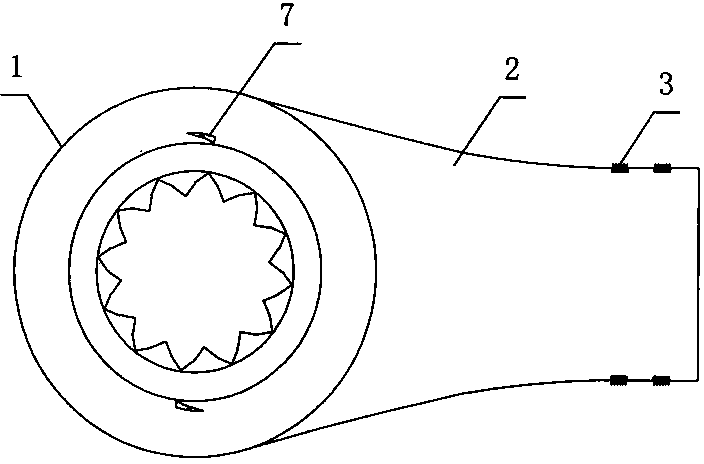

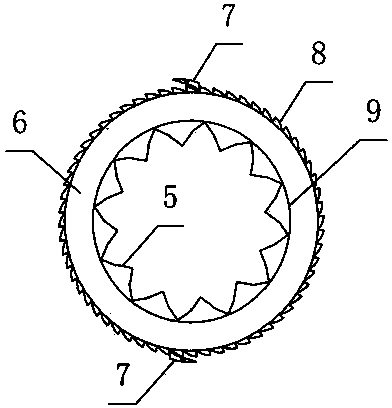

[0039] Figure 1-3 The front end of the fixed connection handle 2 shown in the figure is provided with a ratchet sleeve 1, and the ratchet sleeve is provided with a ratchet 6, the inside of the ratchet is provided with fixed internal teeth 5, the outer circumference of the ratchet is provided with ratchets 8, and the middle of the ratchet is provided with Slide track 9, the middle part of ratchet cover is provided with slide rail groove, and ratchet is installed in the ratchet cover, and the inboard of ratchet cover is provided with anti-retreat groove, is provided with anti-retreat spring in the anti-retreat groove, and the front side of anti-retreat spring is equipped with anti-retraction groove. Return pin 7, the rear side of fixed connection handle is provided with fixed deck 4, and the upper end of fixed deck is provided with tension spring 3.

[0040] Figure 4-5 The upper end of the battery pack 12 shown in the figure is provided with a connecting copper bar 11, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com