Dual mass flywheel

A dual-mass flywheel and flywheel technology, applied in the direction of flywheel, rotation vibration suppression, spring/shock absorber, etc., can solve the problems that the spring cannot be stably and firmly held, and it is impossible to absorb various noises and vibrations, etc., to improve Performance and durability, ensuring competitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, exemplary embodiments of the present invention for achieving the above objects will be described with reference to the accompanying drawings.

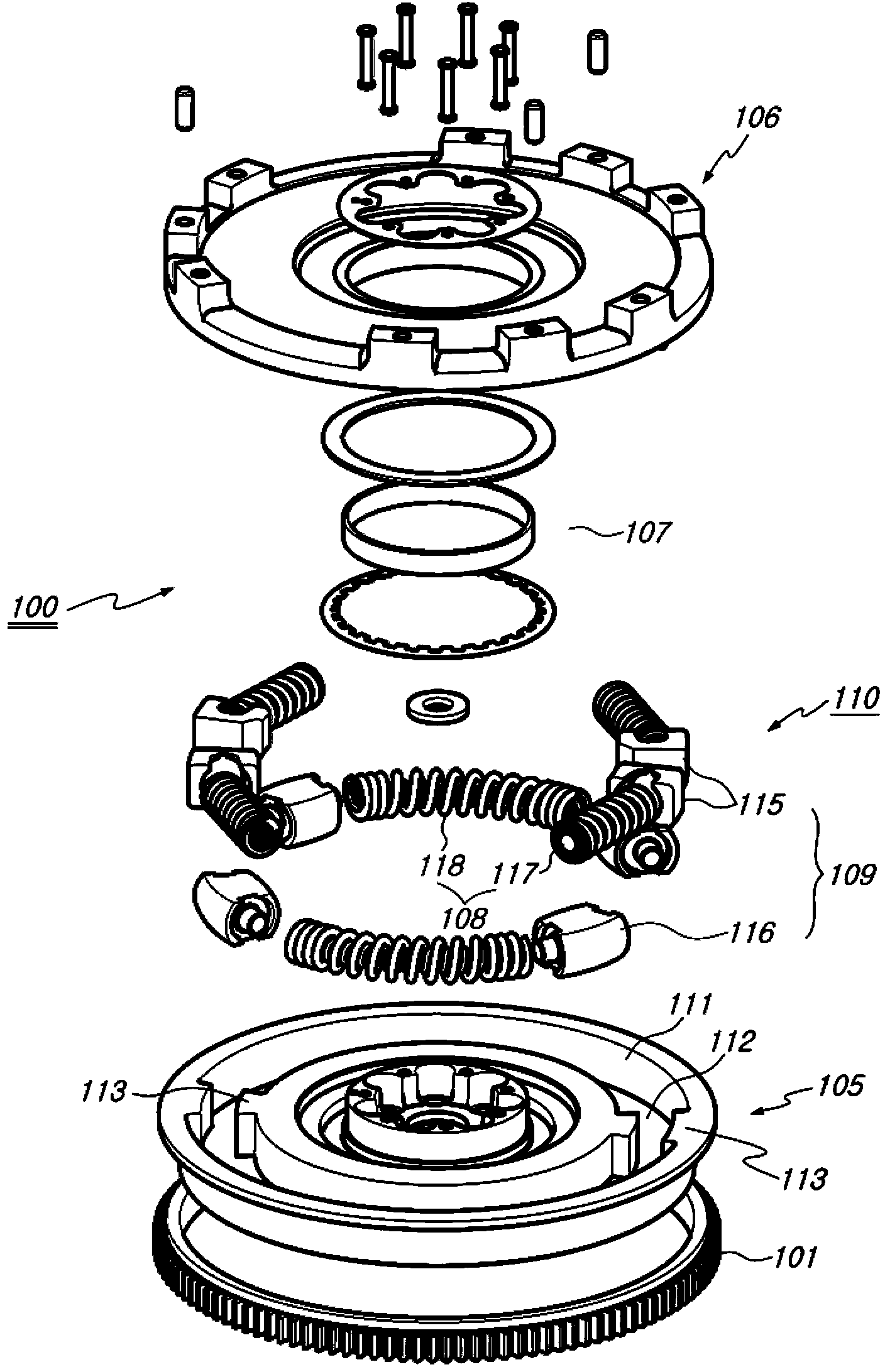

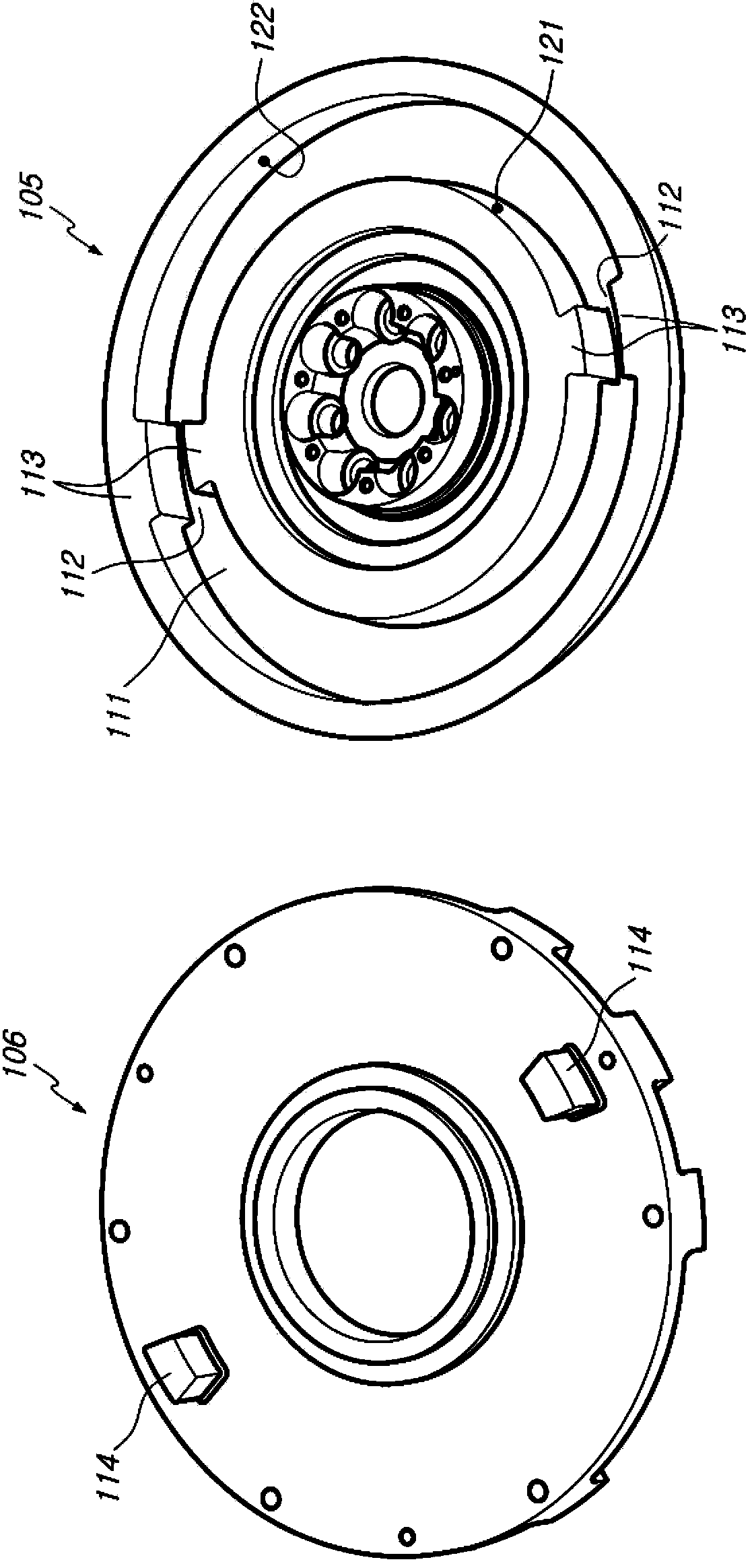

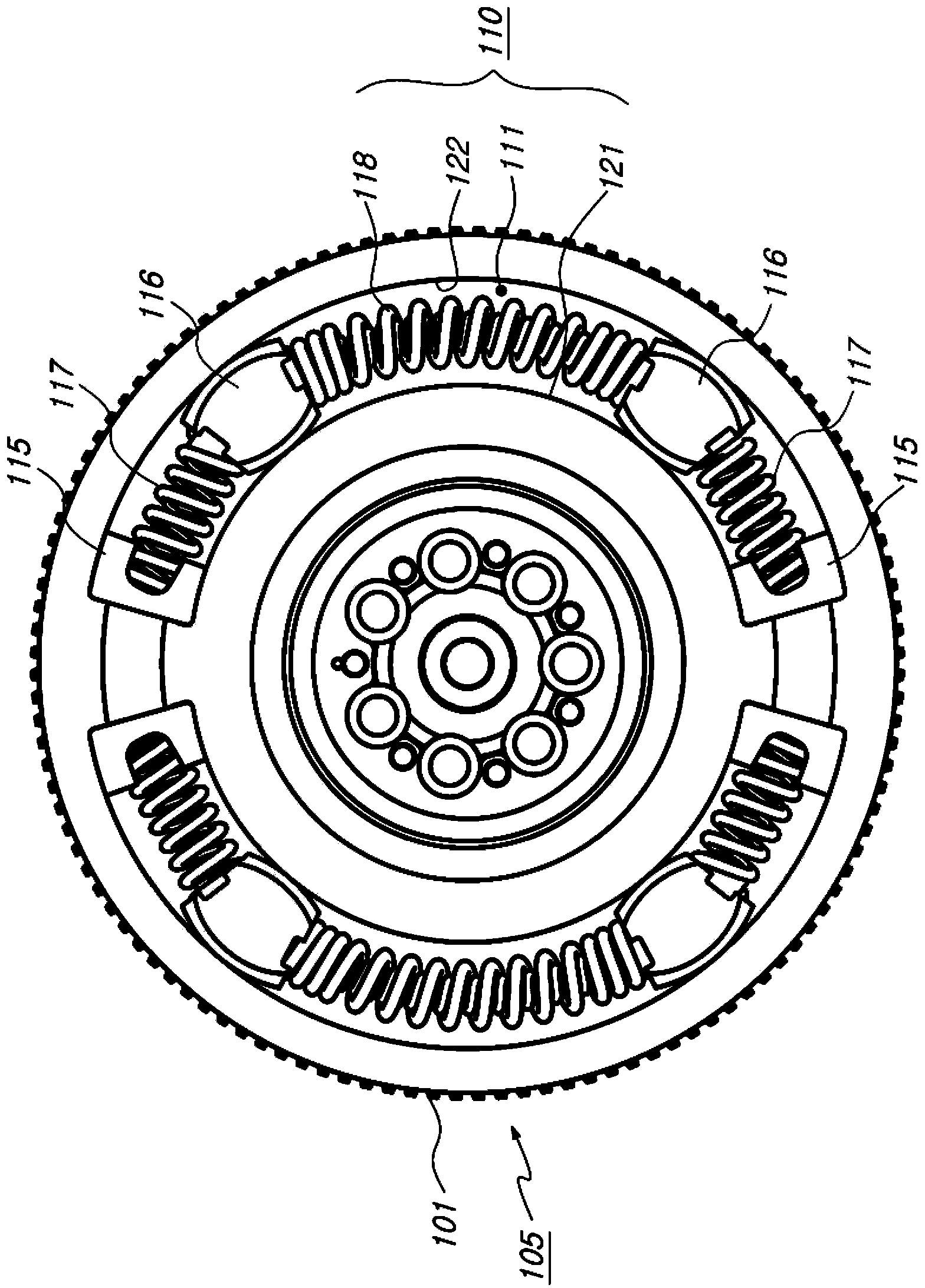

[0027] figure 1 is an exploded perspective view showing a dual mass flywheel according to the present invention. figure 2 is a perspective view showing the top of the dual mass primary flywheel and the bottom of the secondary flywheel according to the present invention. image 3 is a plan view showing a state in which a spring and a spring guide are mounted to the dual mass flywheel according to the present invention. Figure 4 is a perspective view showing a spring guide applied to a dual mass flywheel according to the invention. Figure 5 is a schematic view showing the installation state of the spring guide applied to the dual mass flywheel according to the present invention. Figure 6 is a plan view showing the operating state of the dual mass flywheel according to the present invention.

[0028] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com