Hinge type air preheating sealing device

A technology of air preheating and sealing device, which is applied to the sealing of engines, lighting and heating equipment, and combustion methods, etc. It can solve the problems of insufficient combustion-supporting air in the furnace, increased heat loss of exhaust smoke, and increased ventilation power consumption, etc., to achieve Effects of light weight, increased reliability, and low metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

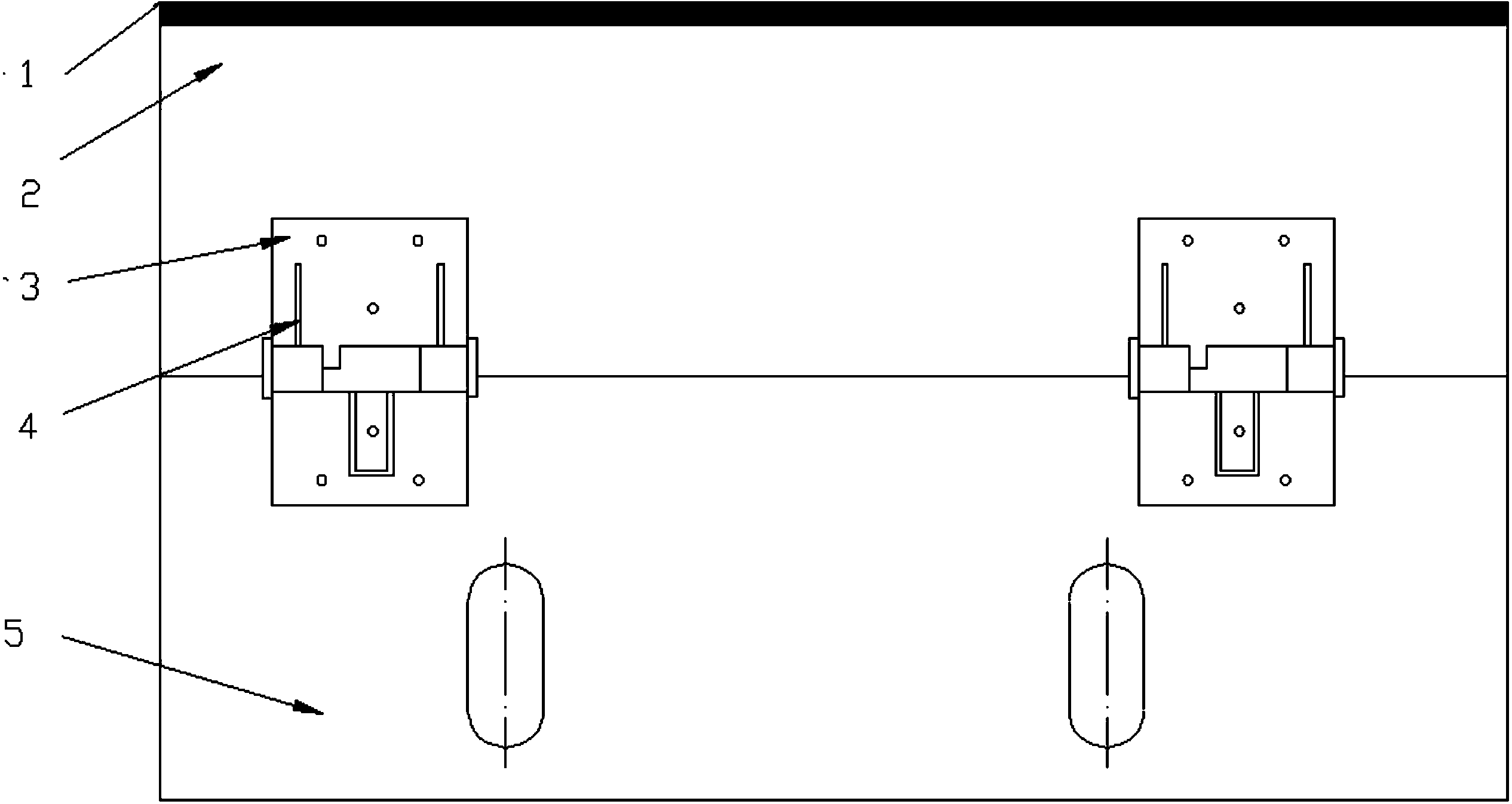

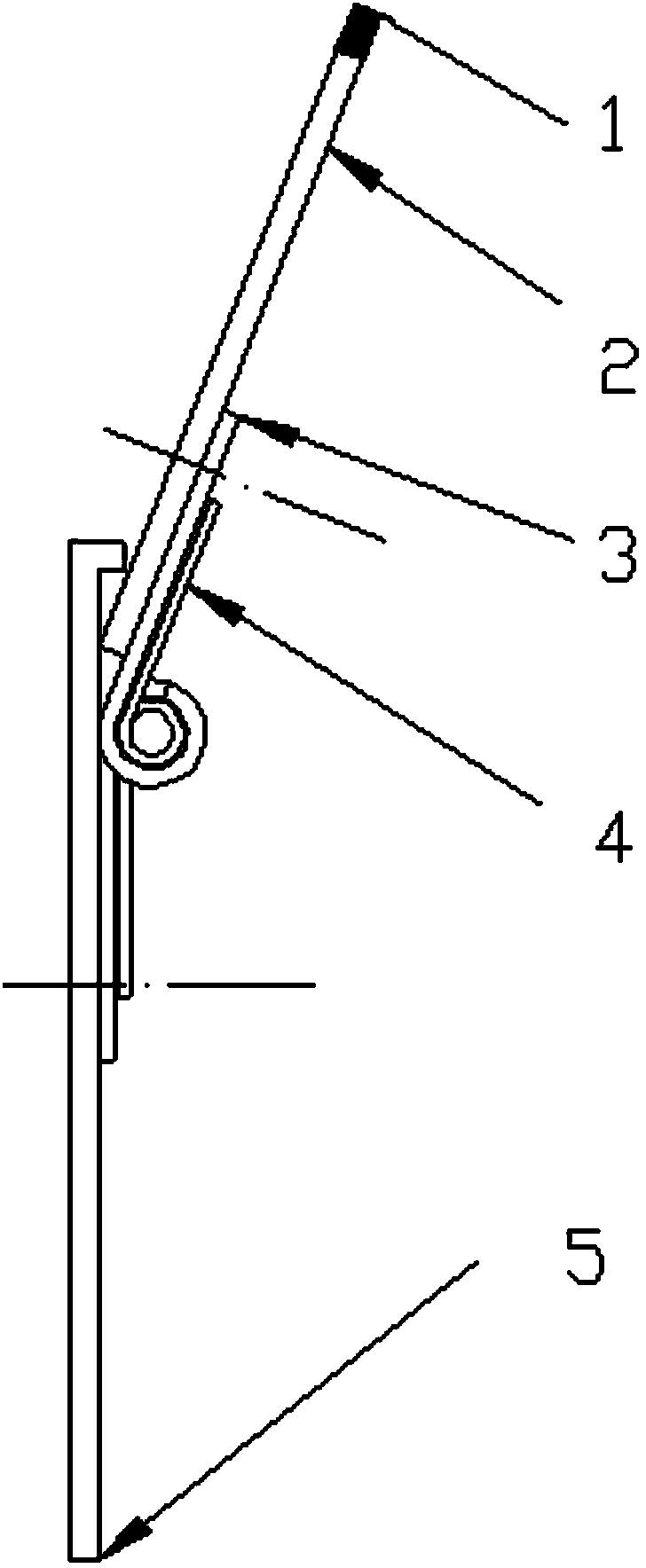

[0038] like figure 1 , figure 2 , is a cold end sealing device, the length of the end of the fixing plate 5 close to the contact baffle 2 exceeds the contact baffle 2, and is bent toward the contact baffle 2.

Embodiment 2

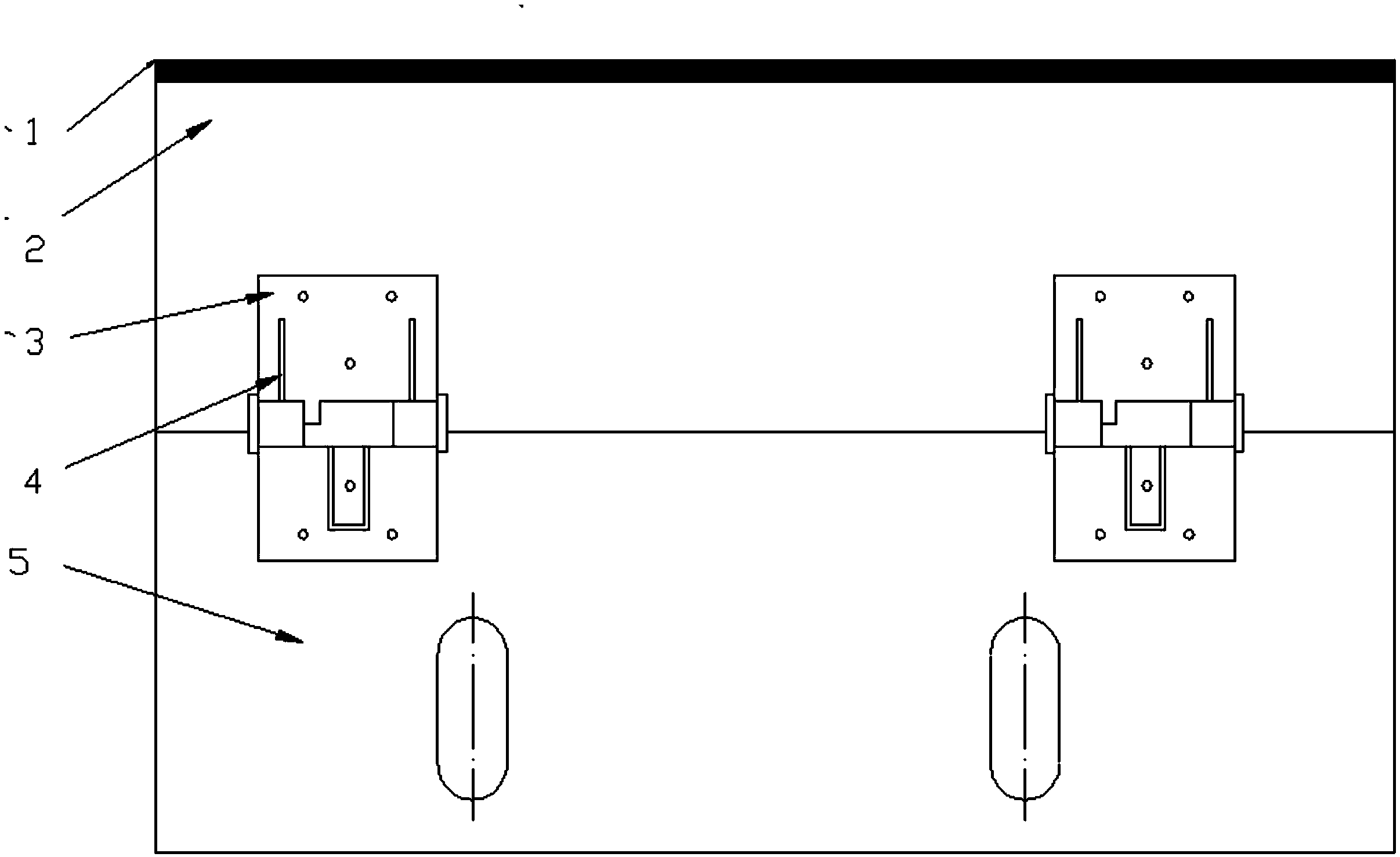

[0040] like image 3 , Figure 4 , is the hot end sealing device, the length of the end of the contact baffle 2 close to the fixed plate 5 exceeds the fixed plate 5, and bends toward the fixed plate 5.

[0041] The upper part of the support part is designed to bend out to prevent the reverse rotation of the upper baffle and at the same time play a sealing role. The design angle of the upper baffle is 15-20 degrees. The upper part of the baffle is in contact with the fan-shaped plate of the air preheater, so a composite ceramic material wear-resistant plate is installed on the top, and weathering steel is used as a whole. The baffle and the bracket are partially perforated and connected by a hinge device.

[0042] Picture of hinge and spring Figure 5-8 shown.

[0043] In the spring hinge device, the length of the spring 2 should be controlled to a reasonable length otherwise it cannot be installed, and the lower half plate 5 sleeve positions of the hinge have a gap 4 to fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com