Detection method and detection device for anesthesia machine controlled leakage and compliance test pipelines

A technology for testing pipelines and detection methods, which is applied in the field of anesthesia machines, and can solve problems such as unconnected pipelines, test errors, leakage, etc., and achieve the effects of simple operation, cost saving, and avoiding test errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below through specific embodiments.

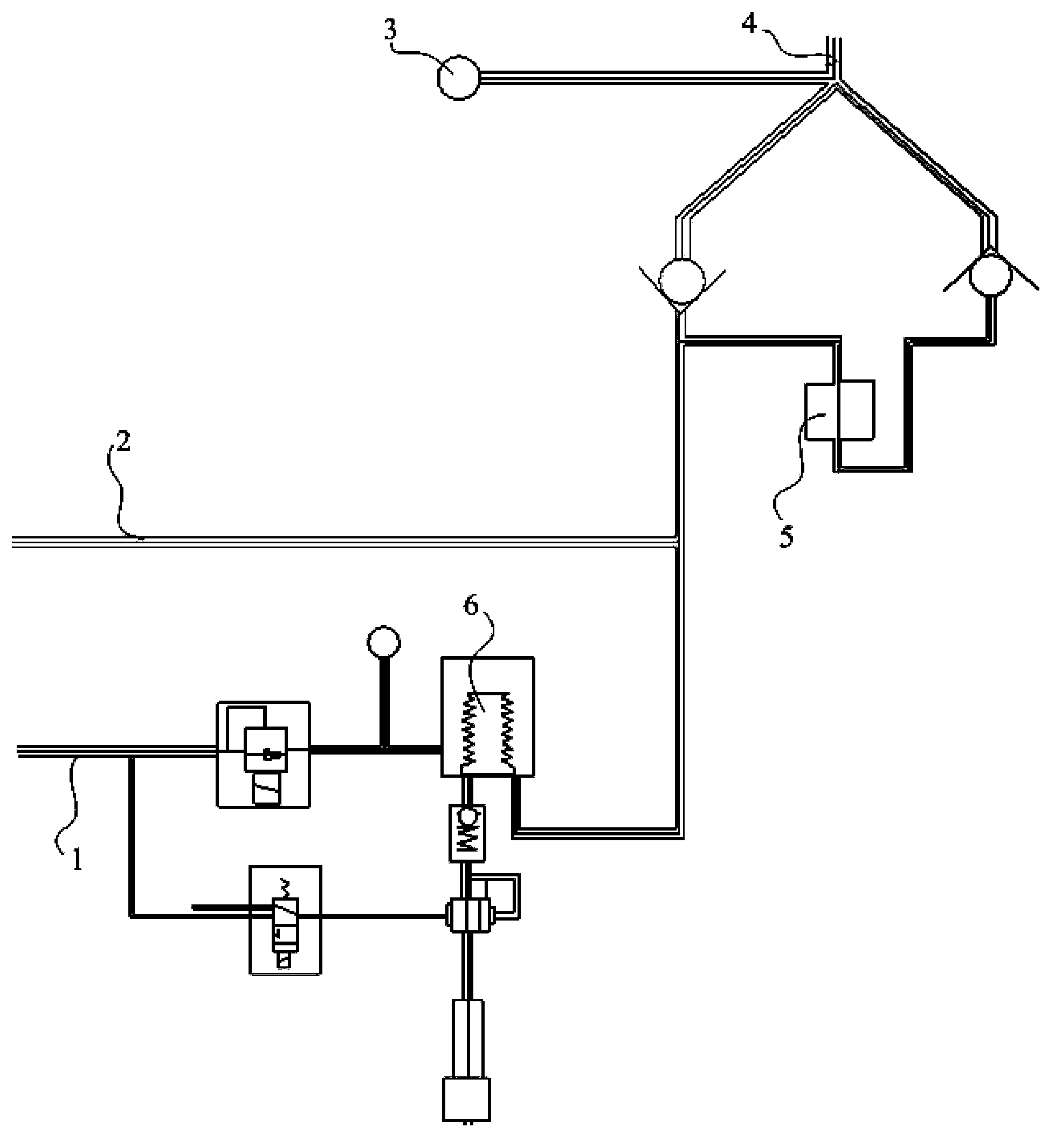

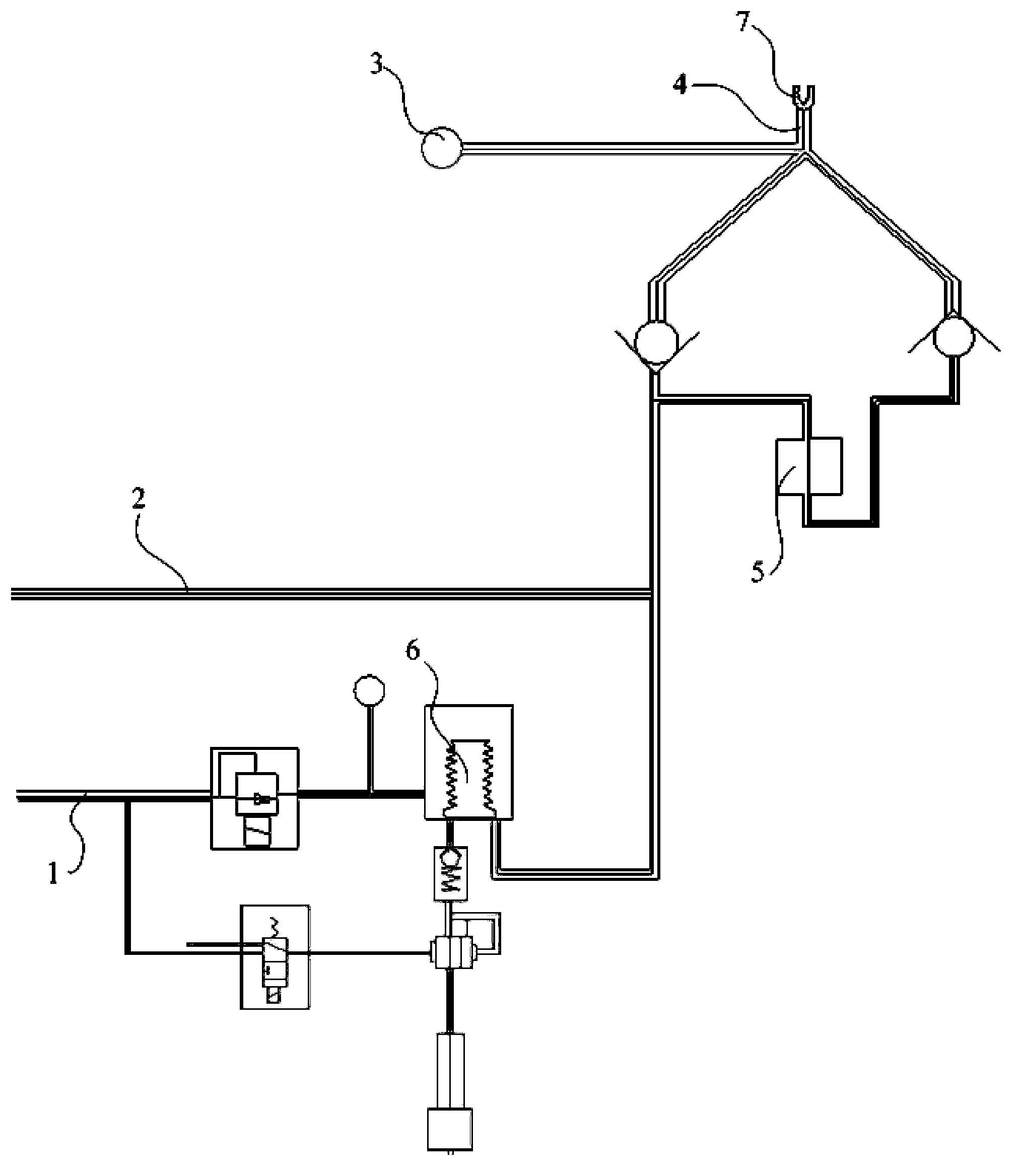

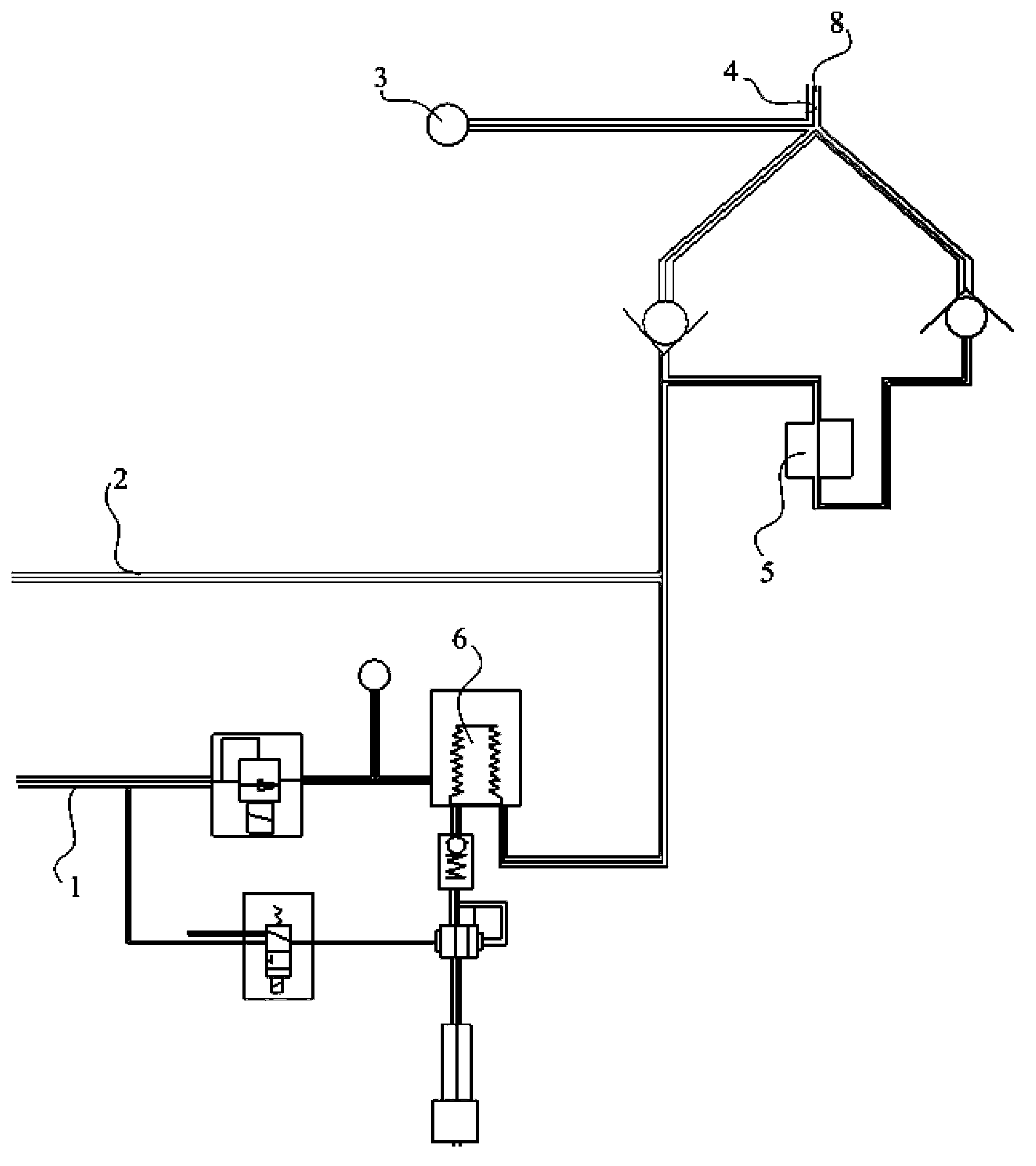

[0038] Such as Figures 1 to 3 As shown, the internal connection structure of the anesthesia machine: the driving gas inlet pipe 1 is connected to the external airway of the folding bag 6, the fresh gas inlet pipe 2 is connected to the folding bag 6, and passes through the fresh gas inlet pipe 2 to the folding bag 6 Into the fresh gas for the lungs to breathe, and at the same time, pass the driving gas into the external airway of the folding bag 6 through the driving gas inlet pipe 1. The specific working process is that the driving gas in the external airway of the foldable bag 6 drives the fresh gas in the foldable bag 6 to flow into the lungs, and the exhaust gas exhaled from the lungs enters the Nashville canal 5, which has a device for absorbing waste gas. Object, the gas exhaled from the lungs passes through the Nashville filling 5, then flows into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com