Integrated handcart with phase testing function and bus grounding function for high-voltage switch cabinet

A high-voltage switchgear, busbar grounding technology, applied in the grounding device of switchgear, pull-out switchgear, switchgear, etc. Realize problems such as mutual comparison of voltages, and achieve the effect of improving test efficiency, wide adaptability, and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

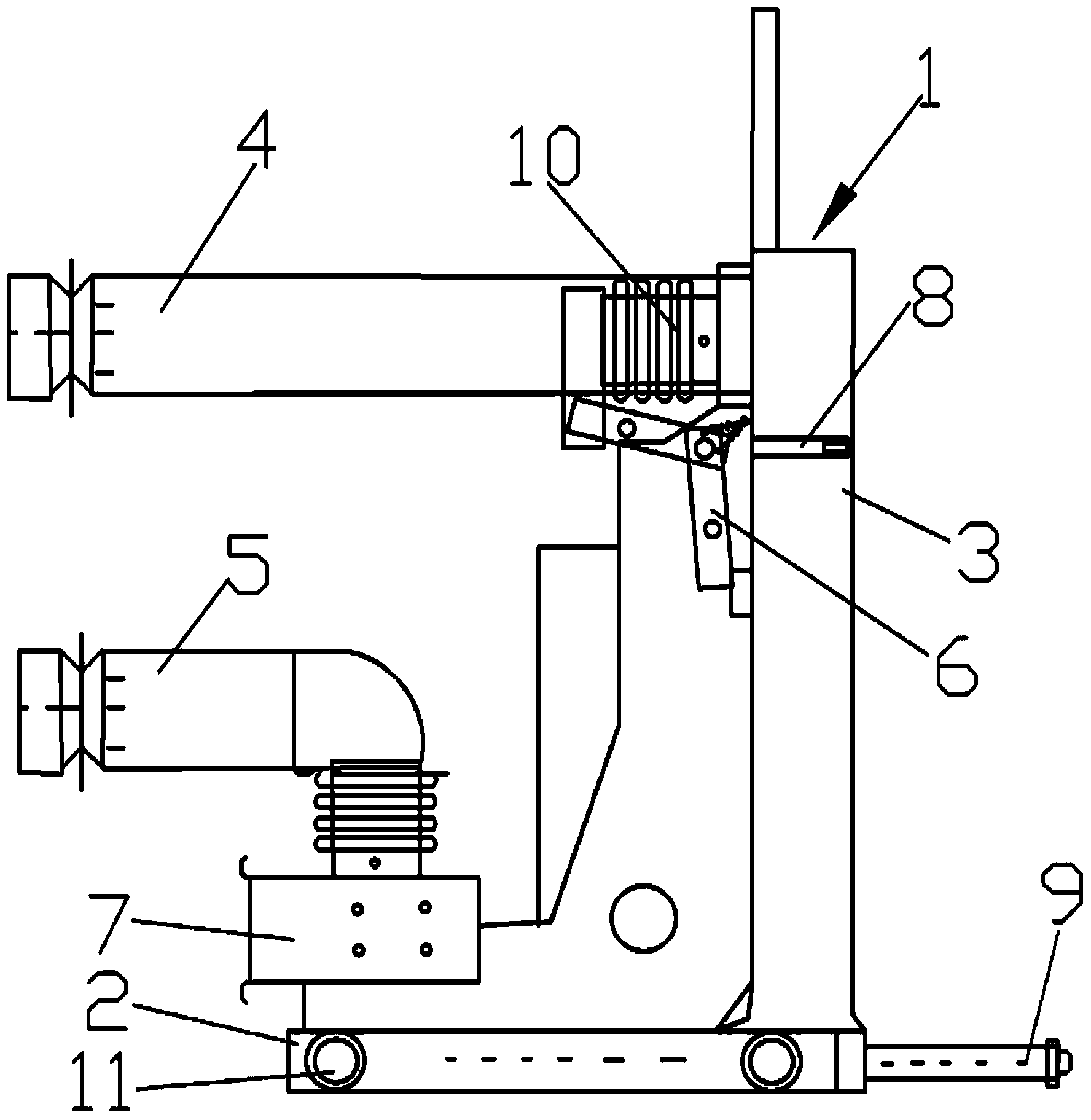

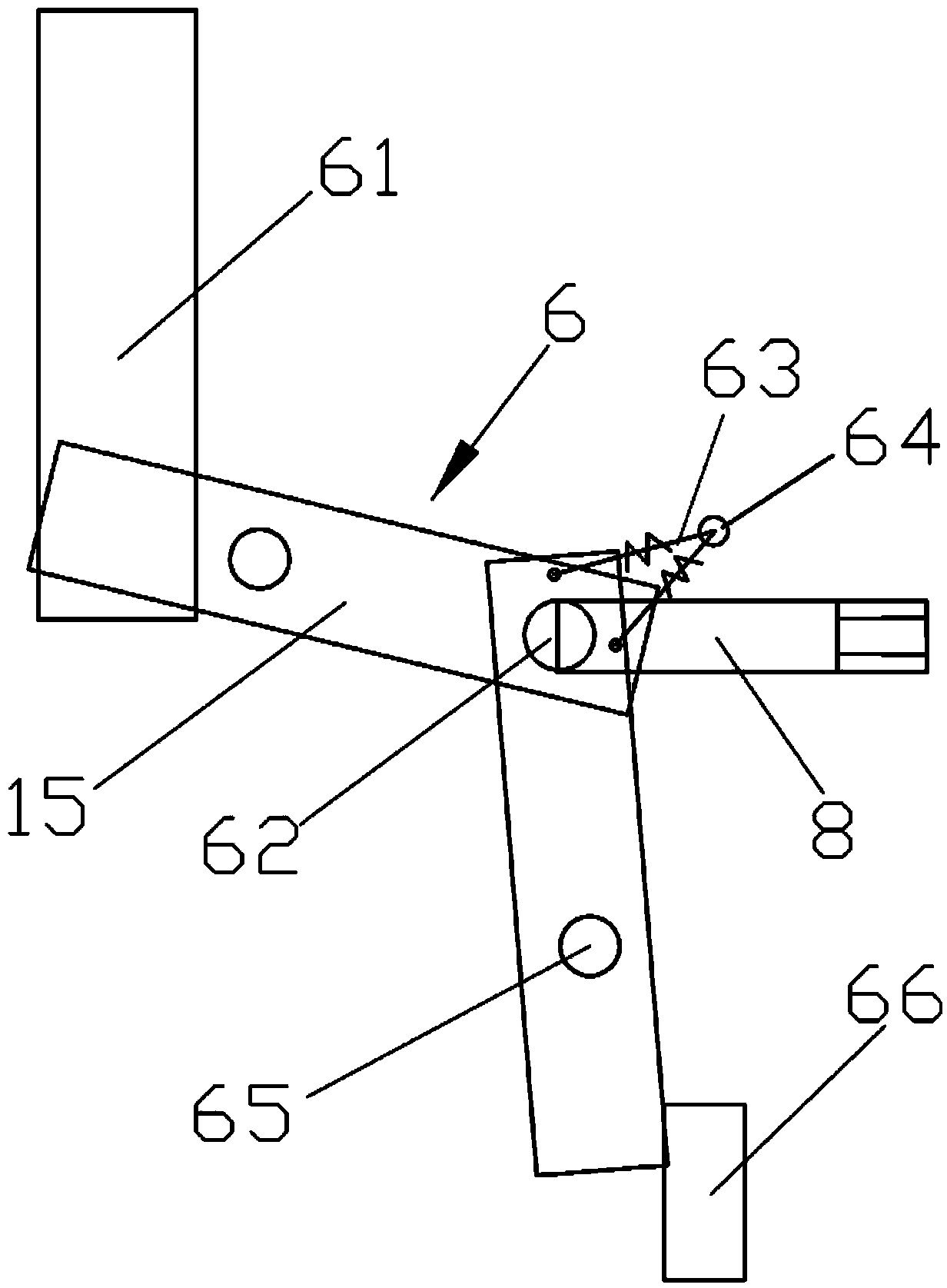

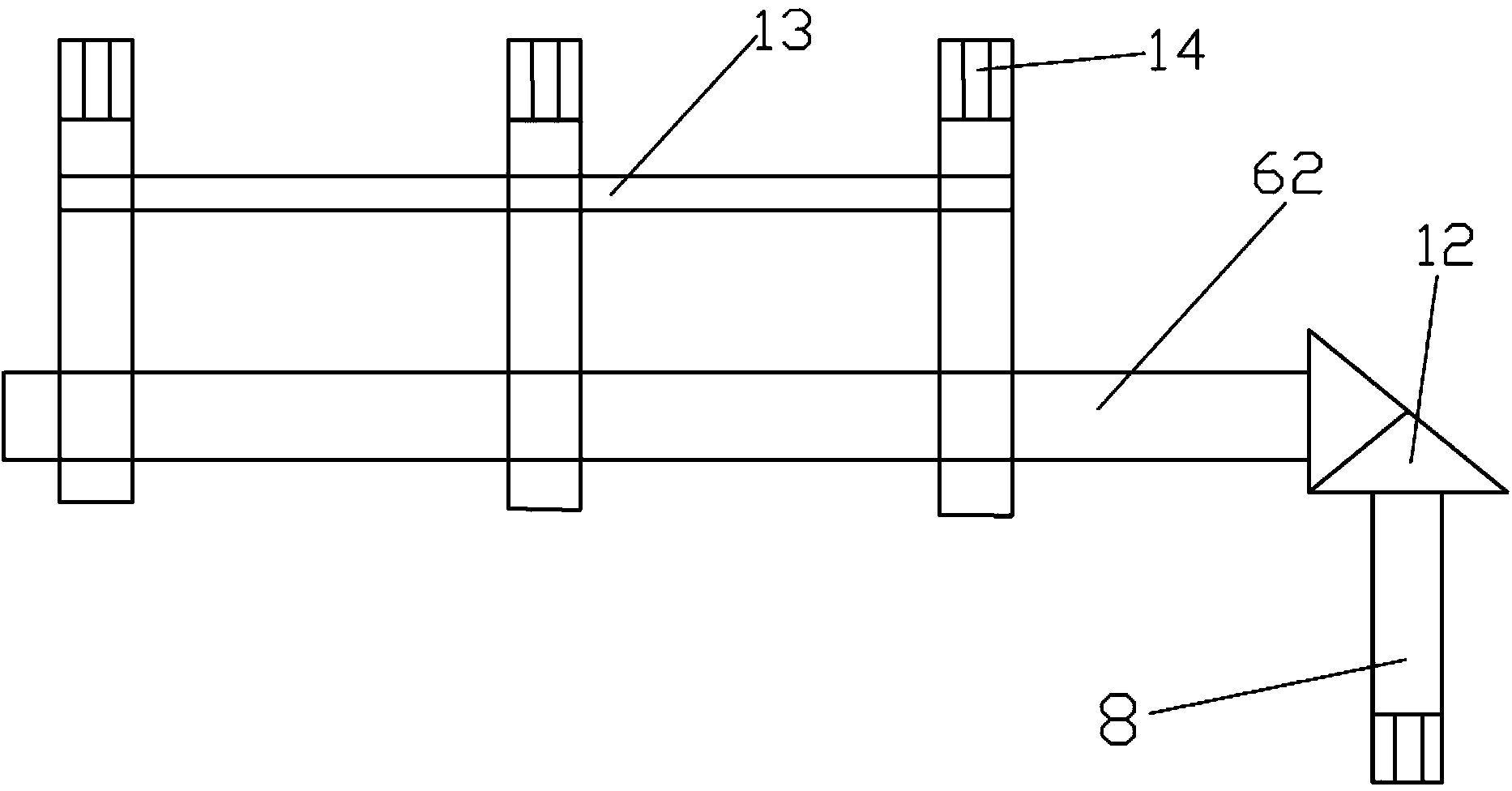

[0023] See attached Figure 1 to Figure 5 , used for the integrated handcart of the high-voltage switchgear phase nuclear and busbar grounding functions, which includes the handcart frame body 1, the busbar side conductive arm 4, the line side conductive arm 5, the busbar side ground knife 6, the valve opening mechanism 7, and the busbar ground Knife operating shaft 8, handcart propulsion mechanism 9 and high voltage induction insulator 10, such as figure 1 shown;

[0024] Described handcart frame body 1 comprises underframe 2 and stand 3, and described stand 3 is vertically fixed on the described underframe 2; Described underframe 2 is provided with a plurality of rollers 11, so that handcart can Move in the switch cabinet; the valve opening mechanism 7 is fixed on the base frame 2, and the line side conductive arm 5 is fixedly arranged above the valve opening mechanism 7; the base frame 2 is also provided with a The handcart propulsion mechanism 9 is used to push the handc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com