Filling machine for filling packaging containers with products and method therefor

A technology for packaging containers and filling machines, which is applied in the types of packaging items, container manufacturing machinery, rigid/semi-rigid container manufacturing, etc., and can solve problems such as wear and damage of packaging walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

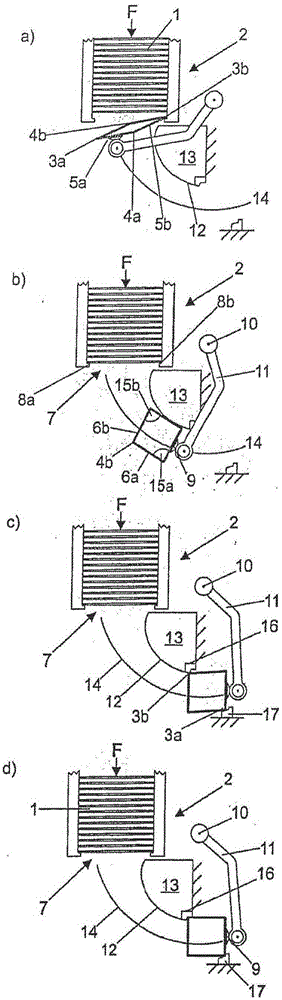

Method used

Image

Examples

Embodiment Construction

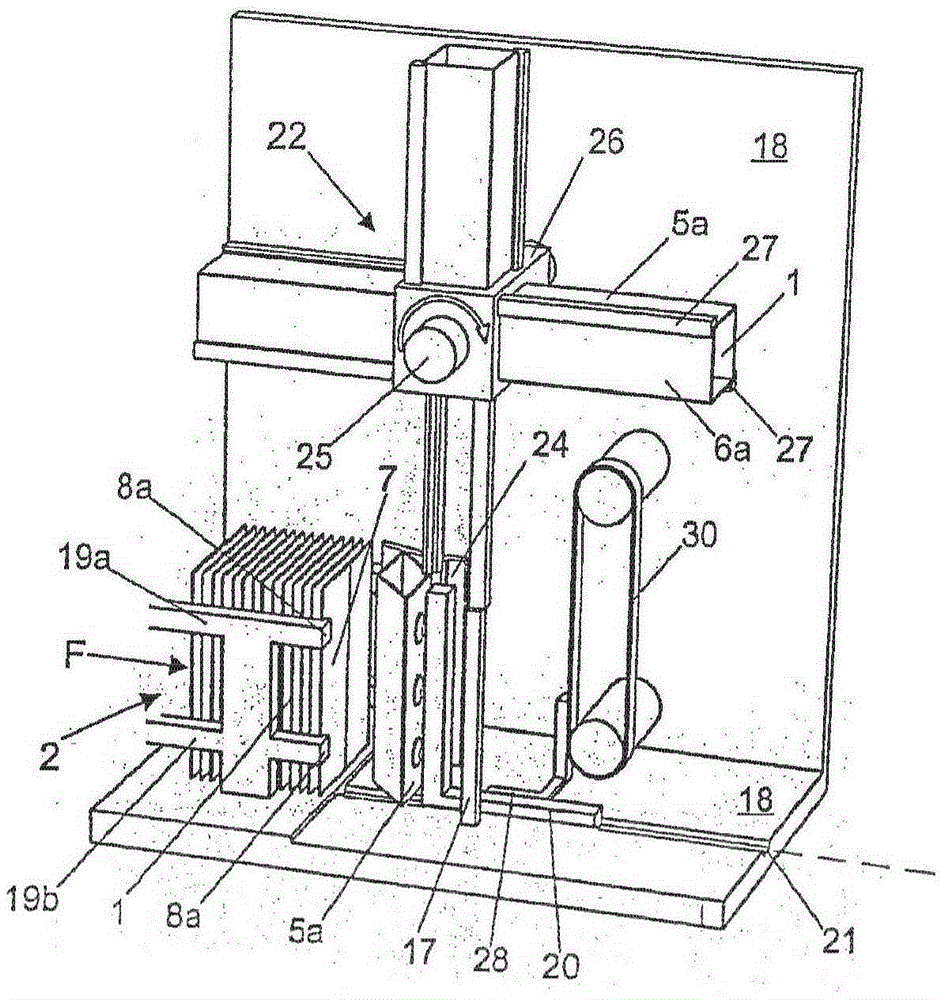

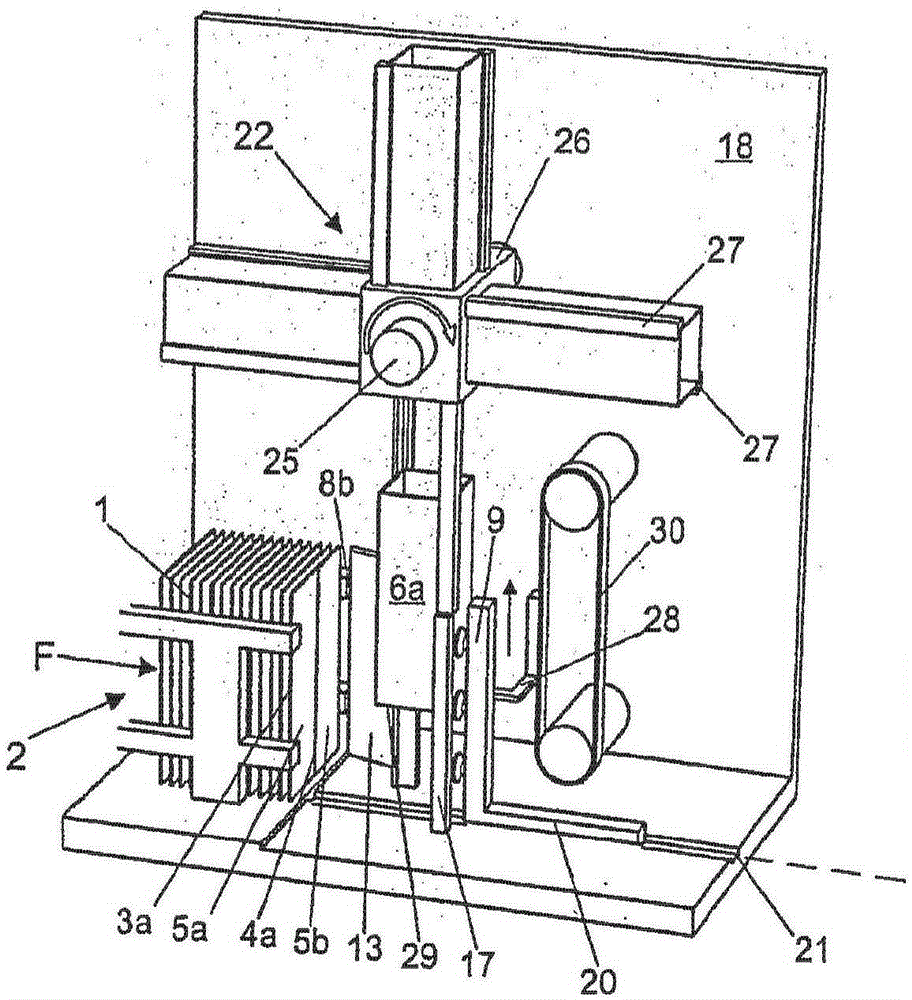

[0043] On the frame ( 18 ) of the filling machine, at the entrance of the conveyor line is arranged a store ( 2 ) for receiving flat-folded packaging shells ( 1 ) for producing packaging containers. The storehouse ( 2 ) includes holding profiles ( 19 a , 19 b ), which rest against the outer flaps ( 3 a , 3 b ) of the packaging shell ( 1 ). On the end faces of the free rods of the holding profiles (19a, 19b) there are blocking elements (8a, 8b) in the form of projections. These blocking elements ( 8 a , 8 b ) prevent the vertical stack of packaging shells ( 1 ) held by the warehouse ( 2 ) from falling out of the warehouse ( 2 ) from the removal side ( 7 ).

[0044] The extraction side ( 7 ) of the warehouse ( 2 ) exposes two of the total front packaging walls ( 5 a , 5 b ) of the total four packaging walls ( 5 a , 5 b , 6 a , 6 b ) of the corresponding front packaging shell ( 1 ) . The extraction and unwinding device located in the warehouse (2) after the conveyor line of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com