Process for producing hardening accelerators for mineral binder compositions

一种固化促进剂、矿物粘结剂的技术,应用在凝结和固化促进剂以及包含这种促进剂的粘结剂组合物,改进矿物粘结剂的早期抗压强度领域,能够解决促进添加剂无法满意地替代热处理或蒸气处理、混凝土扩展度降低、可加工性降低等问题,达到有利于经济性、良好早期抗压强度、简单成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

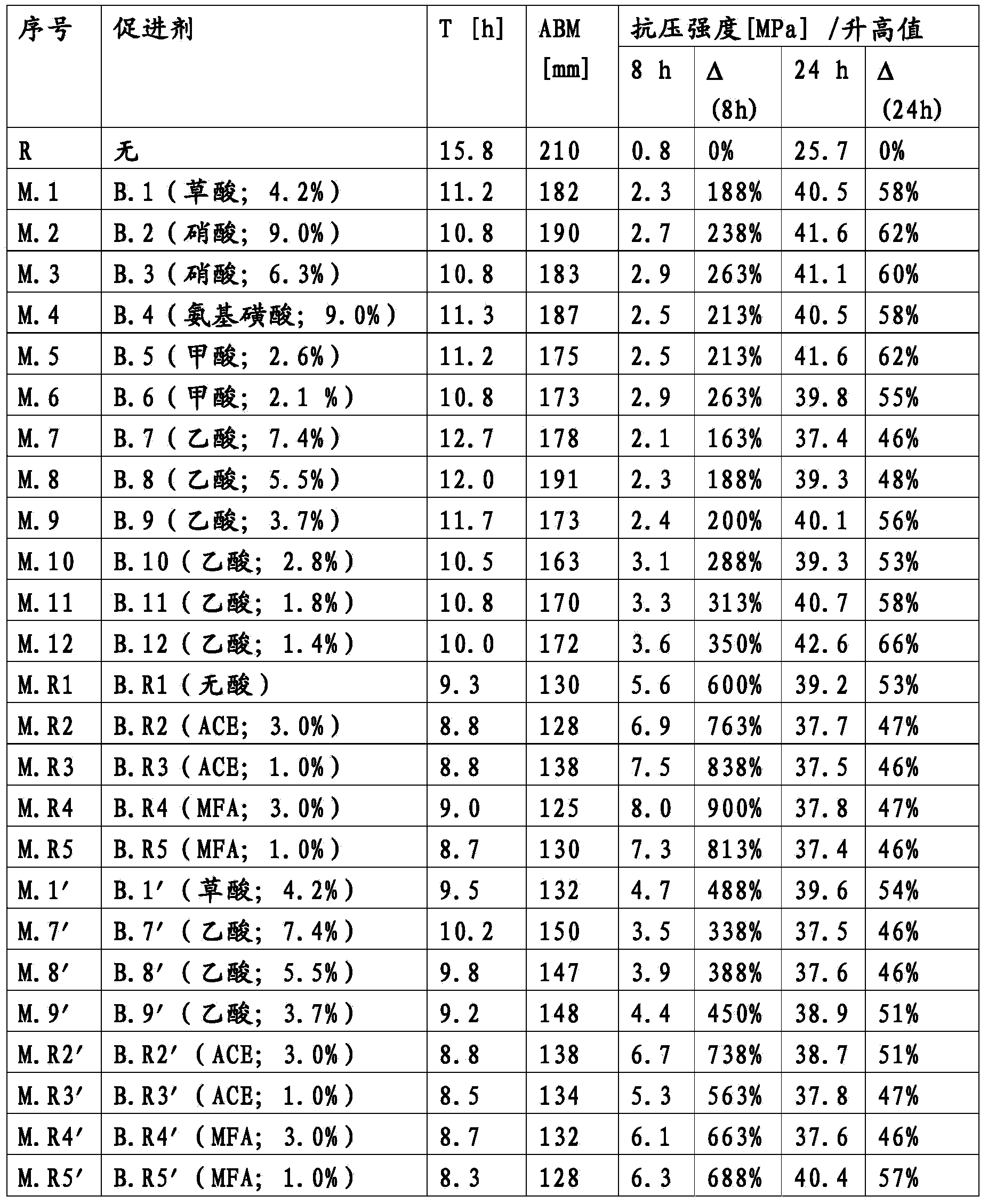

Examples

Embodiment

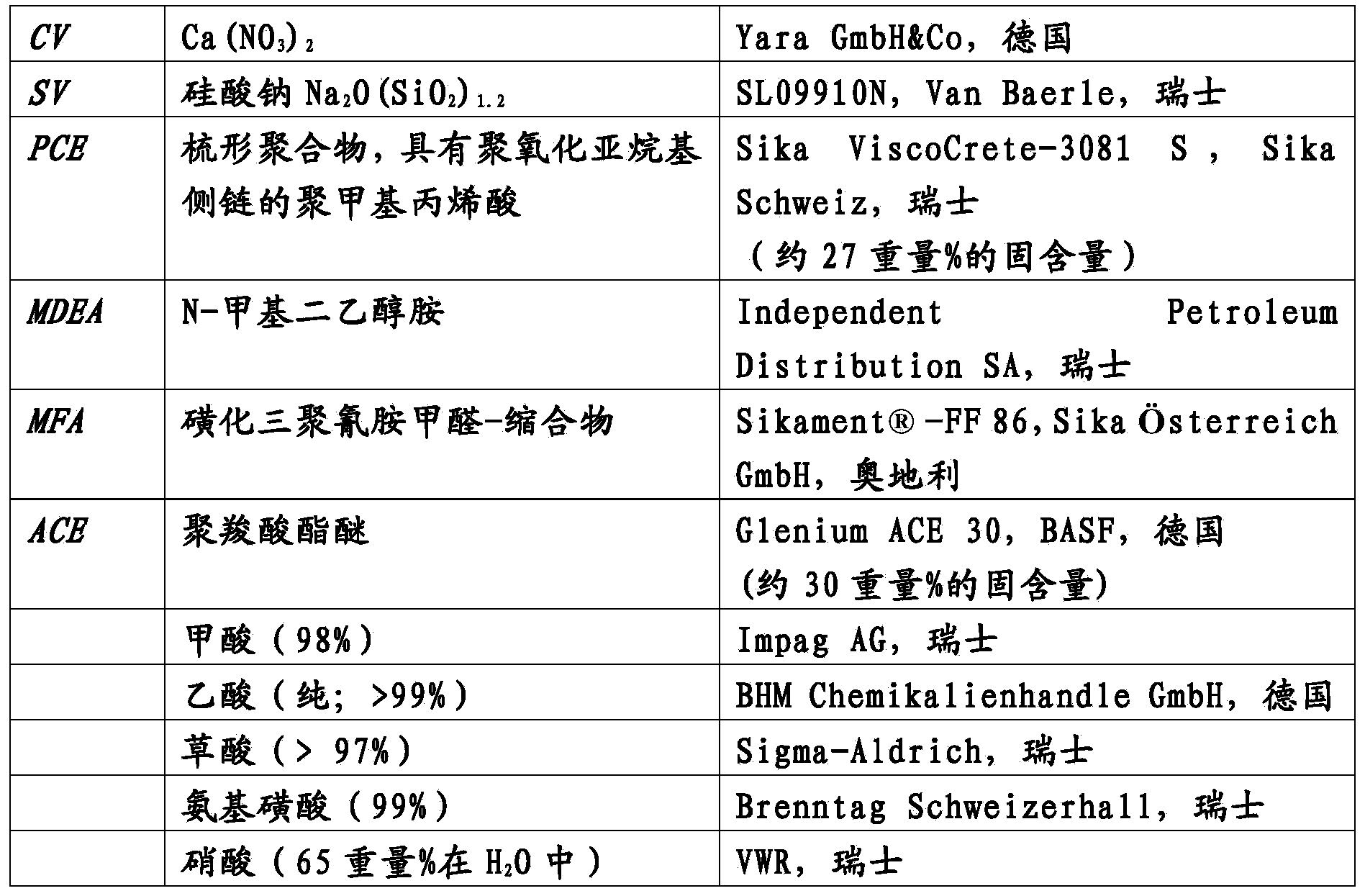

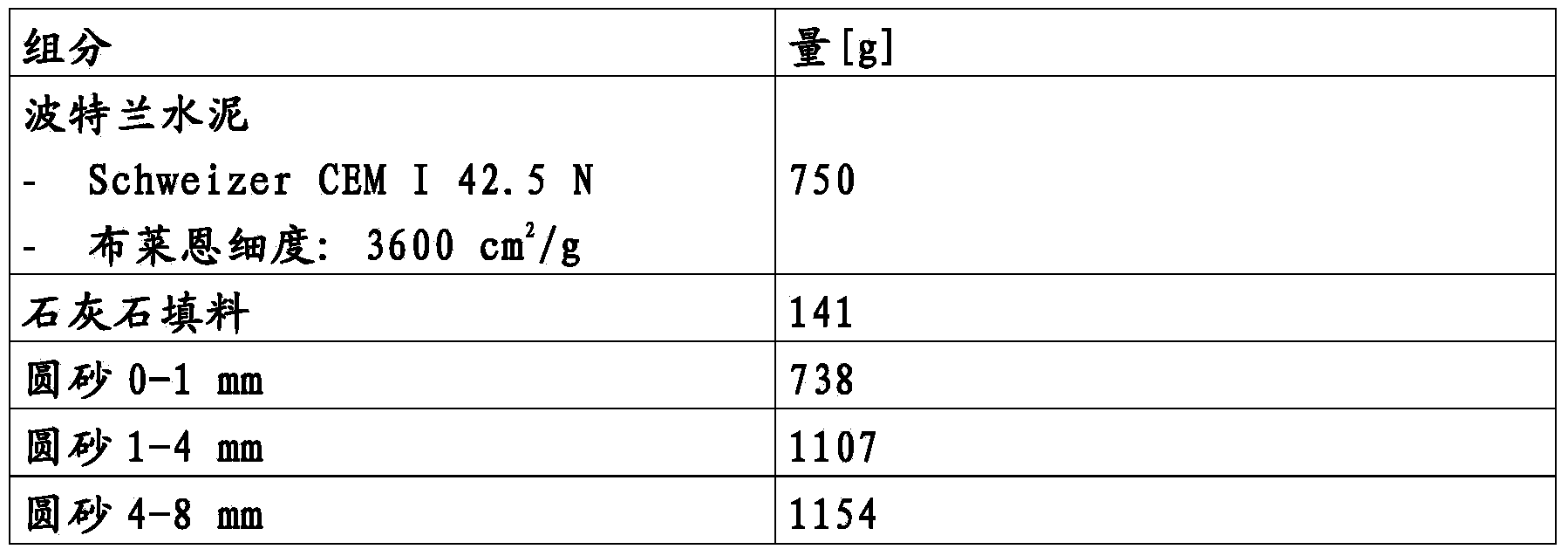

[0117] 1. Raw materials used

[0118] The following raw materials were used in the examples (Table 1):

[0119] Table 1: Raw materials and names used

[0120]

[0121] 2. Preparation of coagulation and curing accelerators

[0122] Accelerators according to the invention and comparative compounds were prepared according to Preparation Methods 1 and 2 described below, using the starting materials used according to Section 1.

[0123] 2.1 Preparation method 1

[0124] Preparation method 1 is based on mixing the acidic compound before reacting the calcium compound CV with the silicon compound SV.

[0125] In a first step, a silicon solution SVL.1 was prepared in which 20% by weight of the silicon compound SV from Table 1 was dissolved in pure water. The resulting solution was stirred for 1 min. SiO 2 :Na 2 The molar ratio of O is 1.2 here.

[0126] In parallel to this, different calcium solutions CVL.1-CVL.12 and CVL.R1-CVL.R5 (for comparison purposes) were prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com