Automobile tailpipe port forming die and die replacing method

A technology for forming molds and automobile exhaust, which is applied in the field of devices for forming and cutting off special-shaped pipe ports, can solve problems such as time-consuming and labor-intensive, and achieve the effects of stable structure, shortened mold change time, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

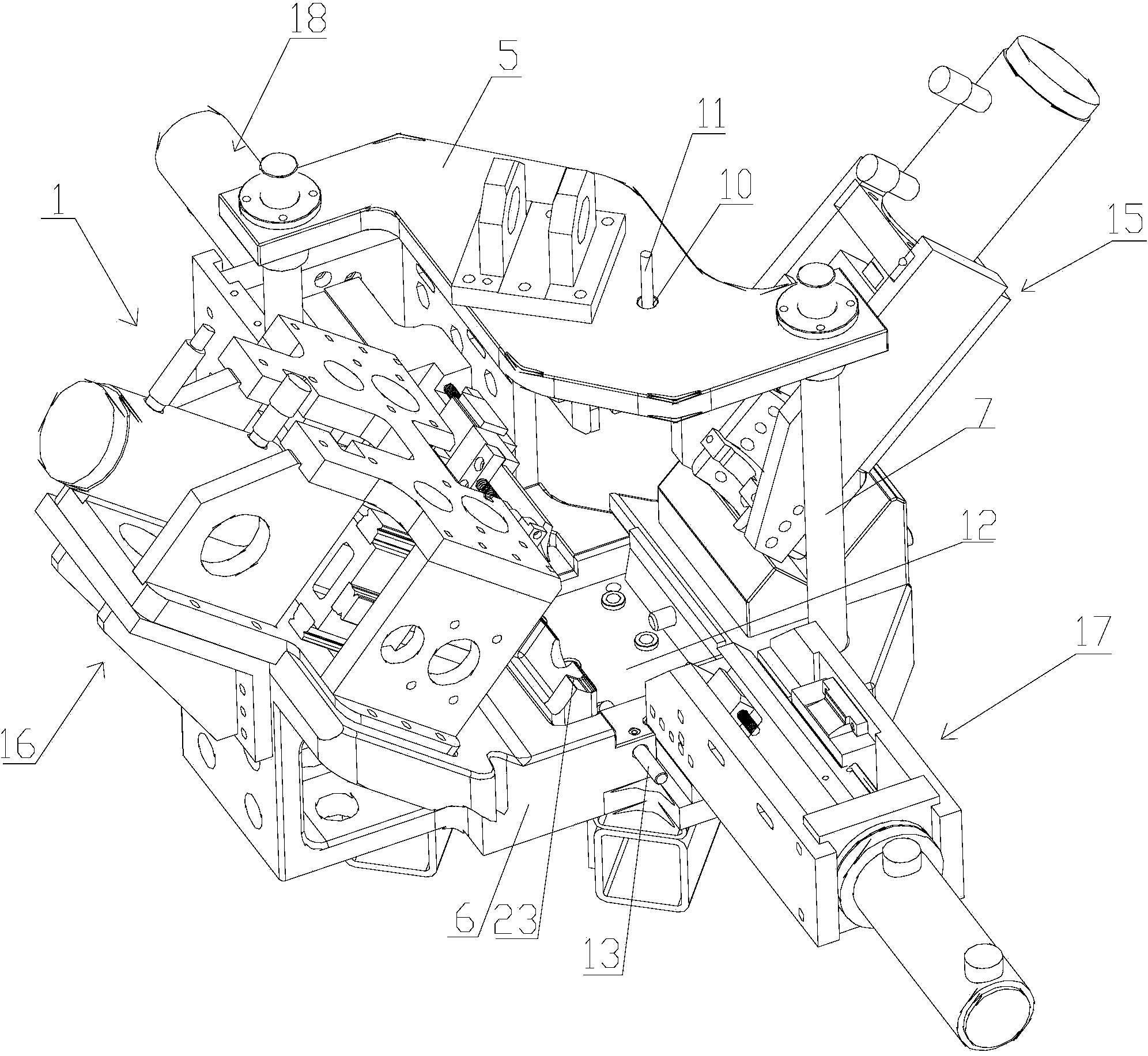

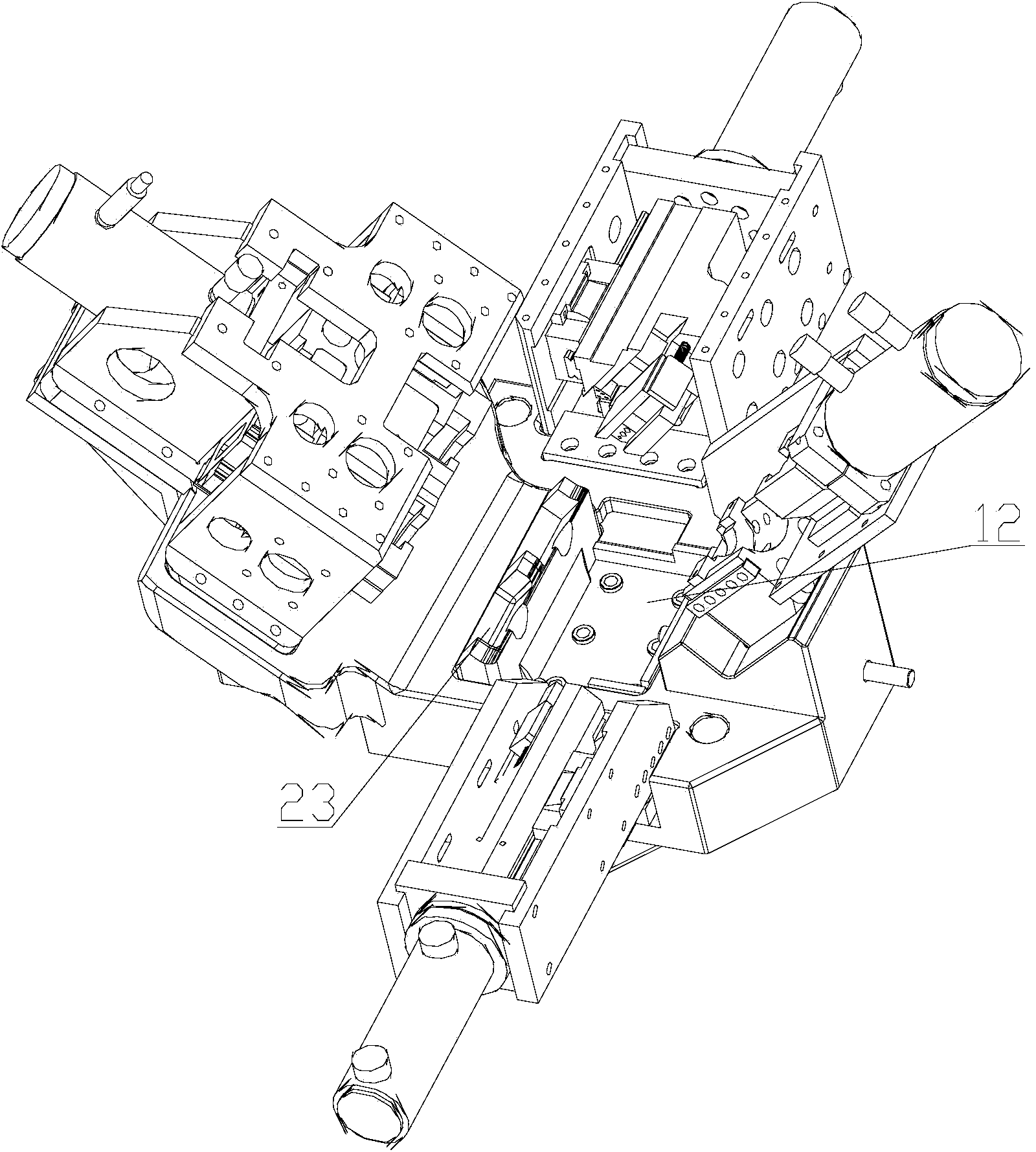

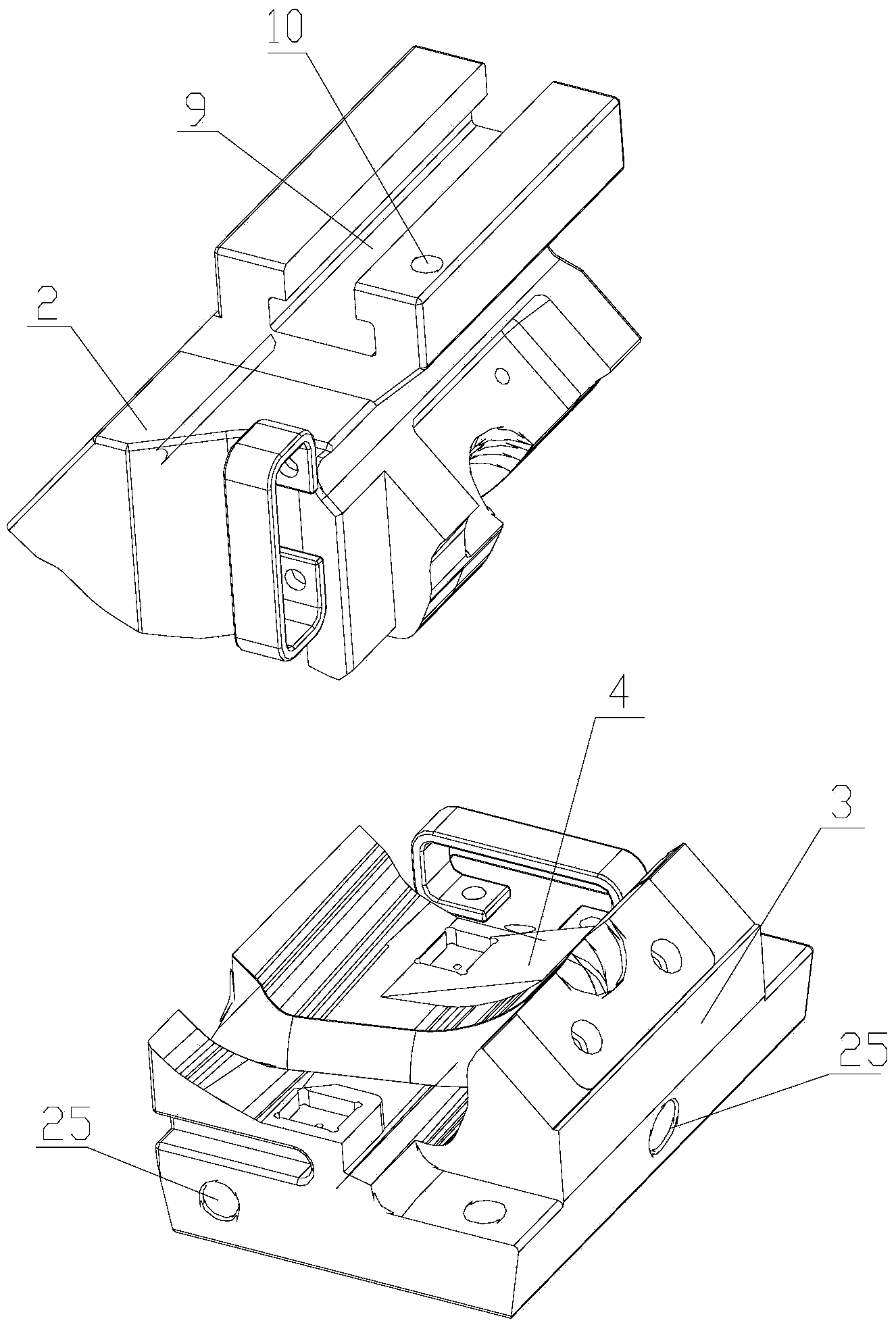

[0053] With reference to the accompanying drawings, an automobile exhaust pipe port forming mold includes a mold frame 1 and four mold cavities. For the convenience of description, the four pairs of mold cavities are divided into mold cavity a, mold cavity b, mold cavity c and mold cavity d. figure 2 An exploded view of the mold cavity a is shown. The mold cavity a includes an upper cavity 2 and a lower cavity 3. After the upper cavity 2 and the lower cavity 3 are engaged, a cavity 4 for clamping a pipe is formed in the middle. The structure of mold cavity b, mold cavity c and mold cavity d is the same as that of mold cavity a, the difference lies in the shape and orientation of the inner cavity to correspond to clamp manifolds of different shapes and specifications. In this way, four pair of mold cavities share one mold frame and can be used to process manifolds of four different specifications.

[0054] An upper template 5 is arranged on the top of the mold frame 1 , a low...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap