Positioning mechanism in forging die

A positioning mechanism and two positioning technology, applied in forging/pressing/hammering machinery, manufacturing tools, forging/pressing/hammer devices, etc., can solve problems such as personal safety cannot be guaranteed, forging defects, low deformation resistance, etc. The effect of reducing manual operation time and labor intensity, reducing contact time, and improving forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

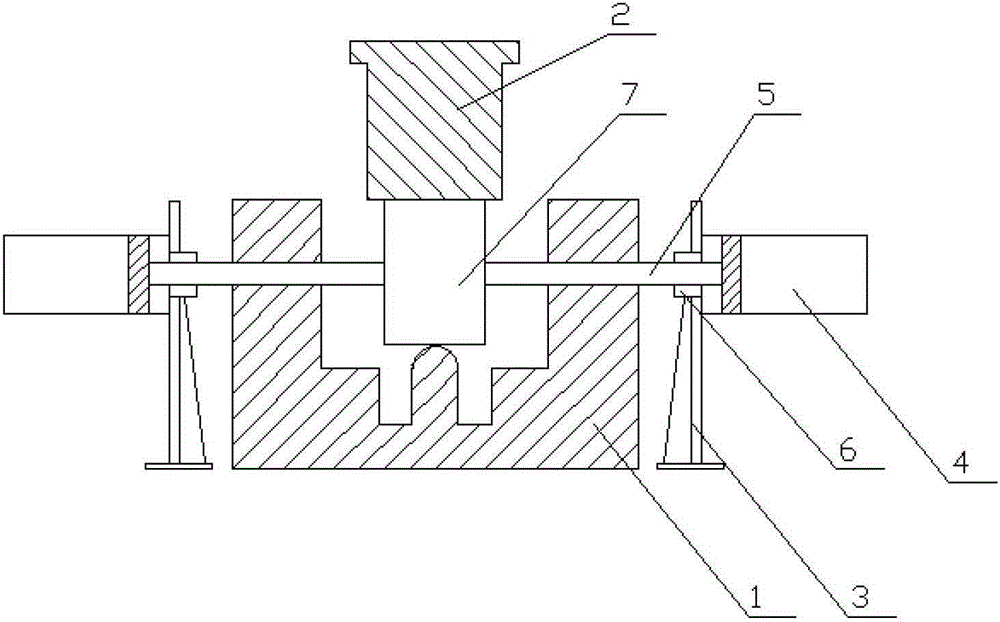

[0012] Embodiment: a positioning mechanism in a forging die, the first and second perforations are respectively provided on the two opposite side walls of the concave die 1 of the forging die, and the first and second positioning mechanisms are fixed on the outside of the forging die. The positioning mechanism is provided with a positioning rod 5 that can be fed horizontally in the axial direction, and the positioning rods 5 of the first and second positioning mechanisms can be slidably inserted into the first and second perforations of the forging die. The positioning mechanism is distributed on two opposite sides of the forging die in a symmetrical state, and they all include a support seat 3, a cylinder 4 and a positioning rod 5. The support seat 3 is relatively fixed and positioned with the forging die, and the cylinder body of the cylinder 4 is fixed on the support seat 3. On the top, the positioning rod 5 is fixedly connected with the piston of the cylinder 4. In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com