Coupling hole precision machining method

A technology of precision machining and dual small holes, which is applied in the field of precision machining of dual small holes, and can solve problems such as difficulty in ensuring the accuracy of the spatial position of the collision point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

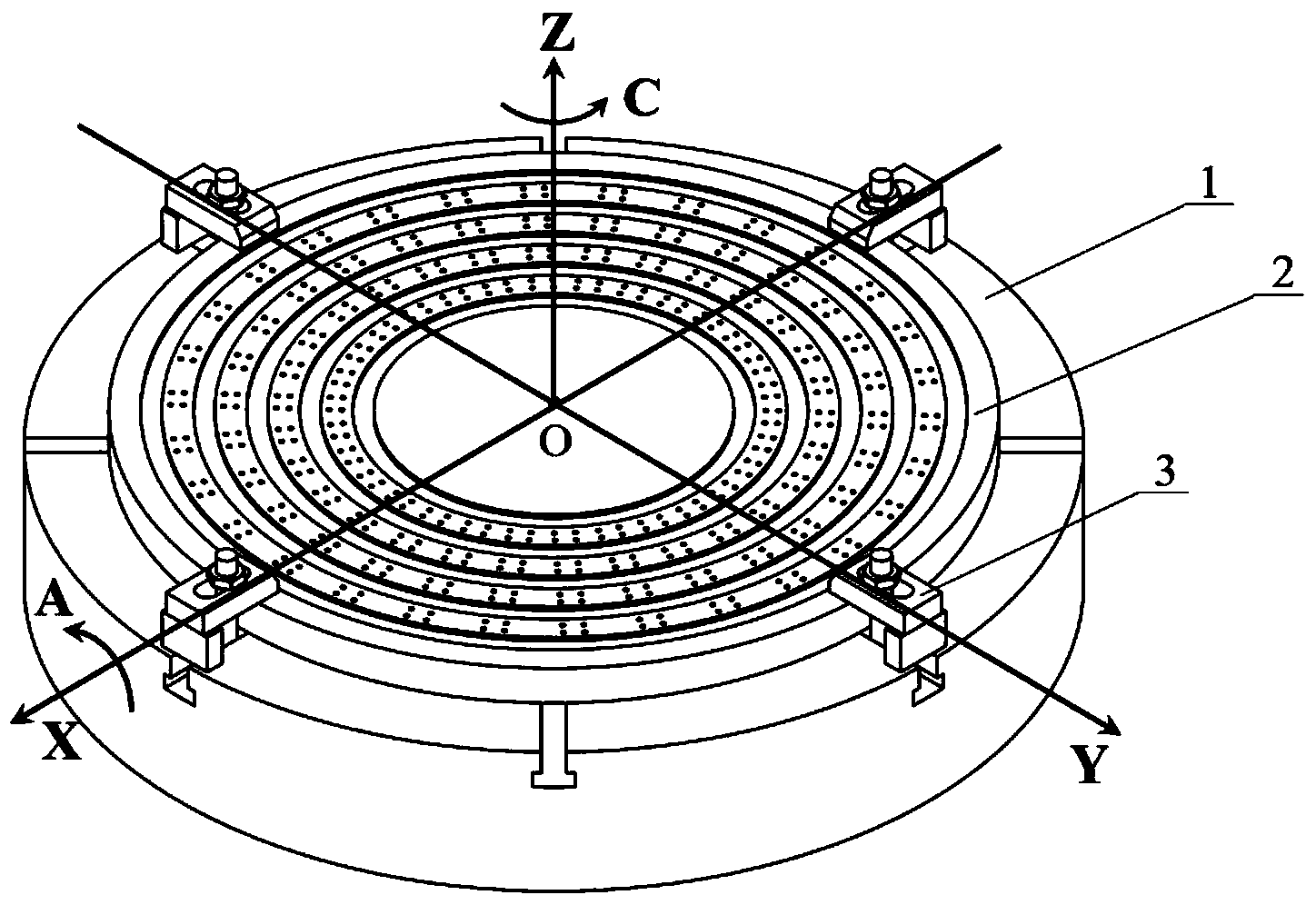

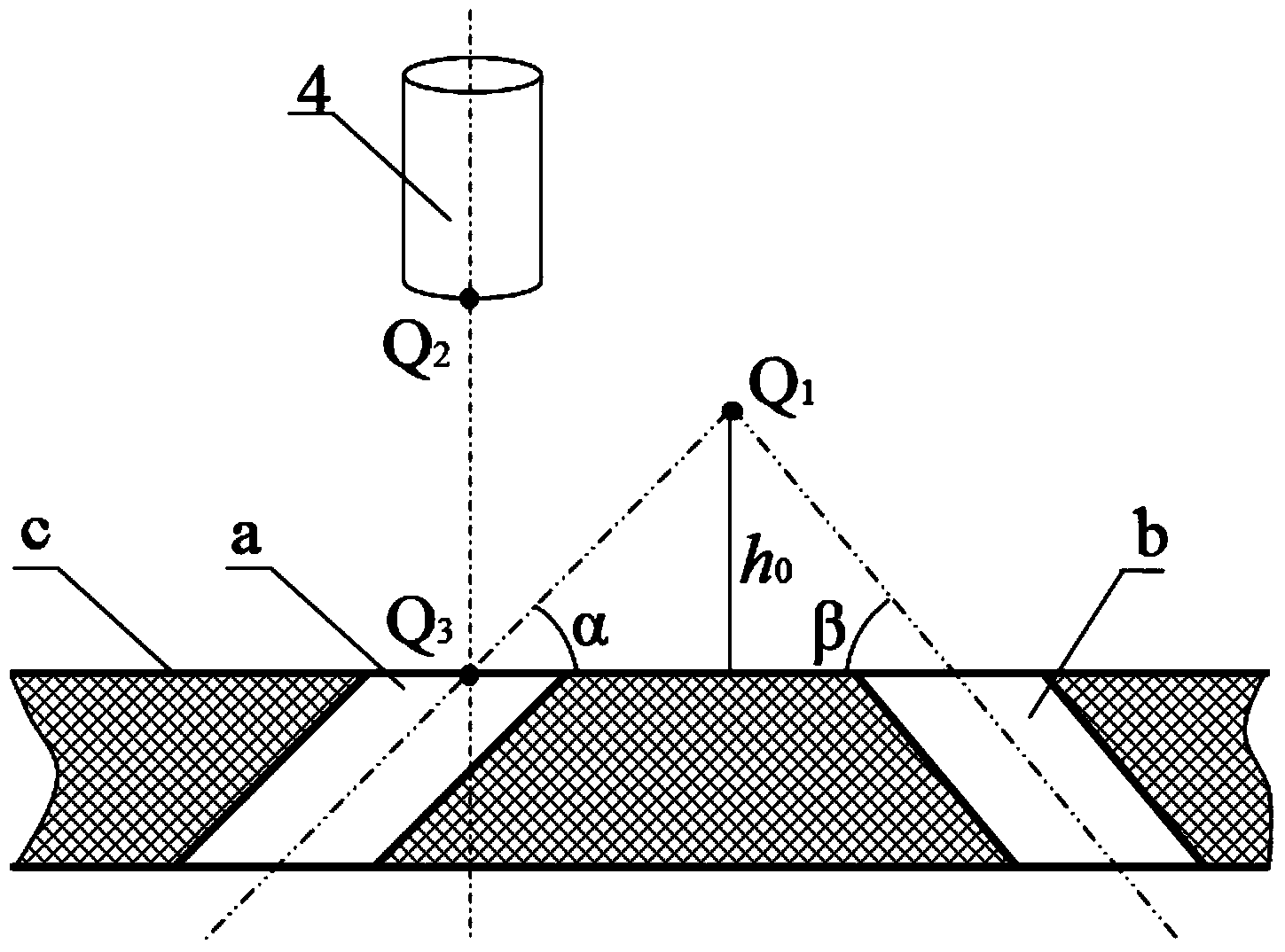

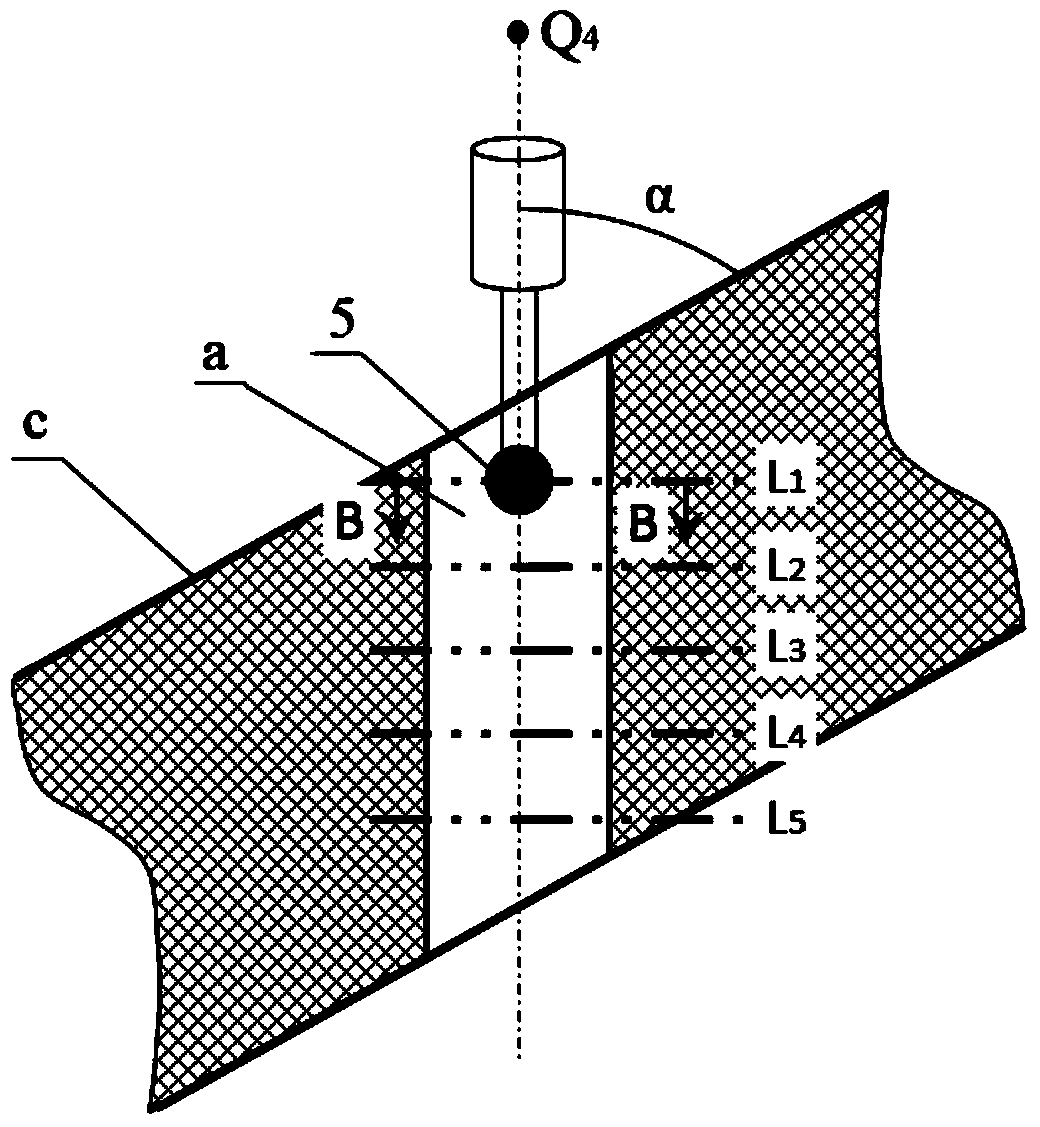

[0043] The embodiment of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions, and the process of precision machining of dual small holes will be described. The diameter of the workpiece is 450mm, the thickness is 10mm, the diameter of the dual small holes is 1mm, and the design height of the collision point is h 0 is 15mm, the inclination angle α and the inclination angle β are both 45 degrees, the distance R is 200mm, the distance H is 10mm, and the two dual holes are through holes.

[0044] The first step is to ensure that the spindle of the machine tool is in a safe position before the workpiece 2 is clamped to avoid collisions; figure 1 As shown, the workpiece 2 is placed on the rotary table 1, and the workpiece 2 is adjusted to be coaxial with the rotary table 1. Four pressure plates 3 with bolts are evenly distributed on the rotary table 1, and the pressure plates 3 press the workpiece 2 to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com