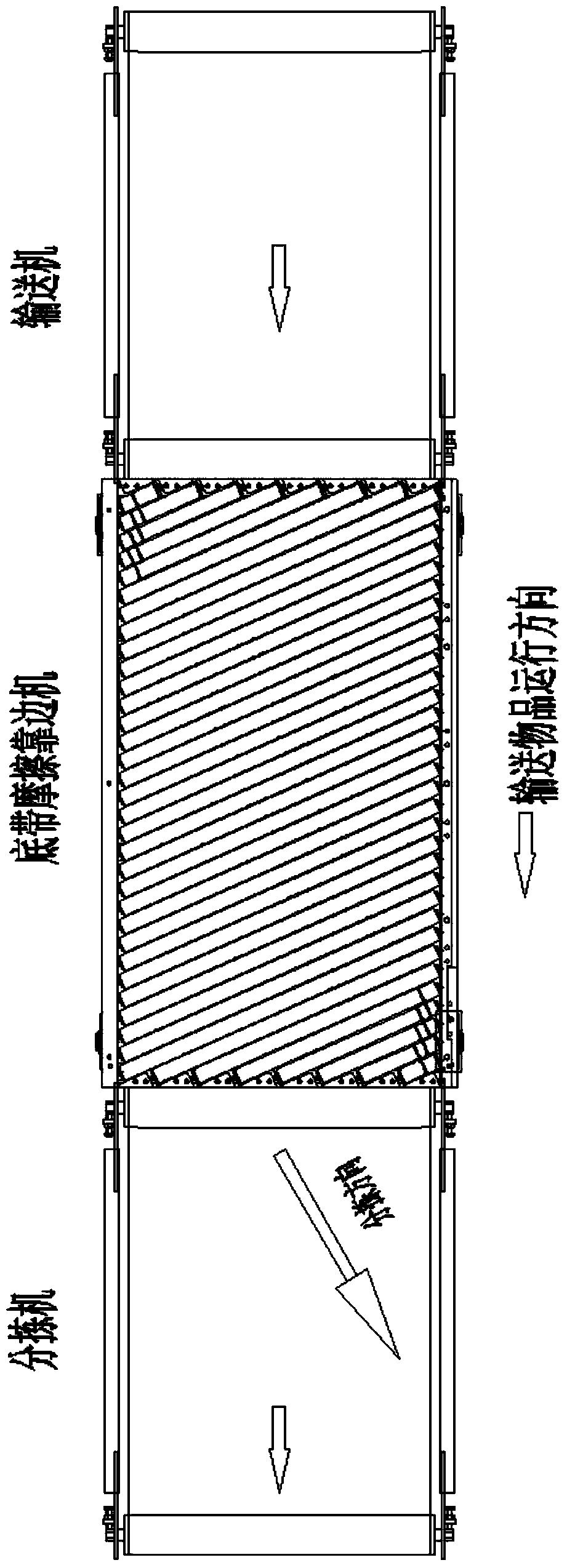

Bottom belt rubbing side-approaching machine

A technology of bottom belt and belt conveyor, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., and can solve the problem of limiting the bottom belt friction and edge machine's conveying speed and carrying capacity, low conveying speed and load-bearing capacity, and affecting conveying stability To achieve the effect of improving the conveying capacity and stability, facilitating production and installation, and increasing the range of types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

[0051] Based on the principle of improving the conveying speed and carrying capacity of the bottom belt friction edge machine and reducing the vibration and noise of the equipment, the present invention designs a new type of side belt conveyor to replace the edge guardrail, avoids friction between the conveyed goods and the edge guardrail, and improves the friction edge of the bottom belt The conveying capacity and stability of the machine.

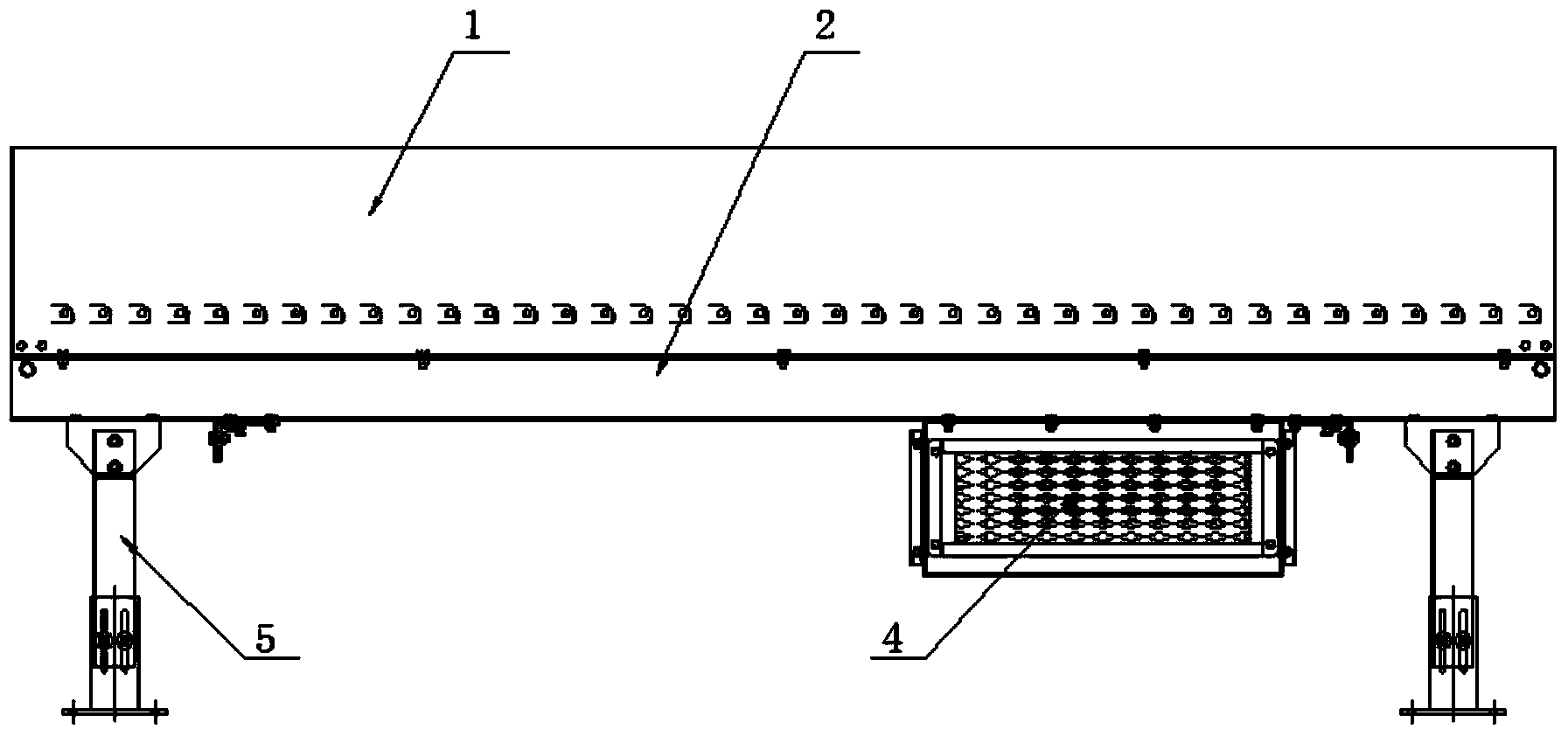

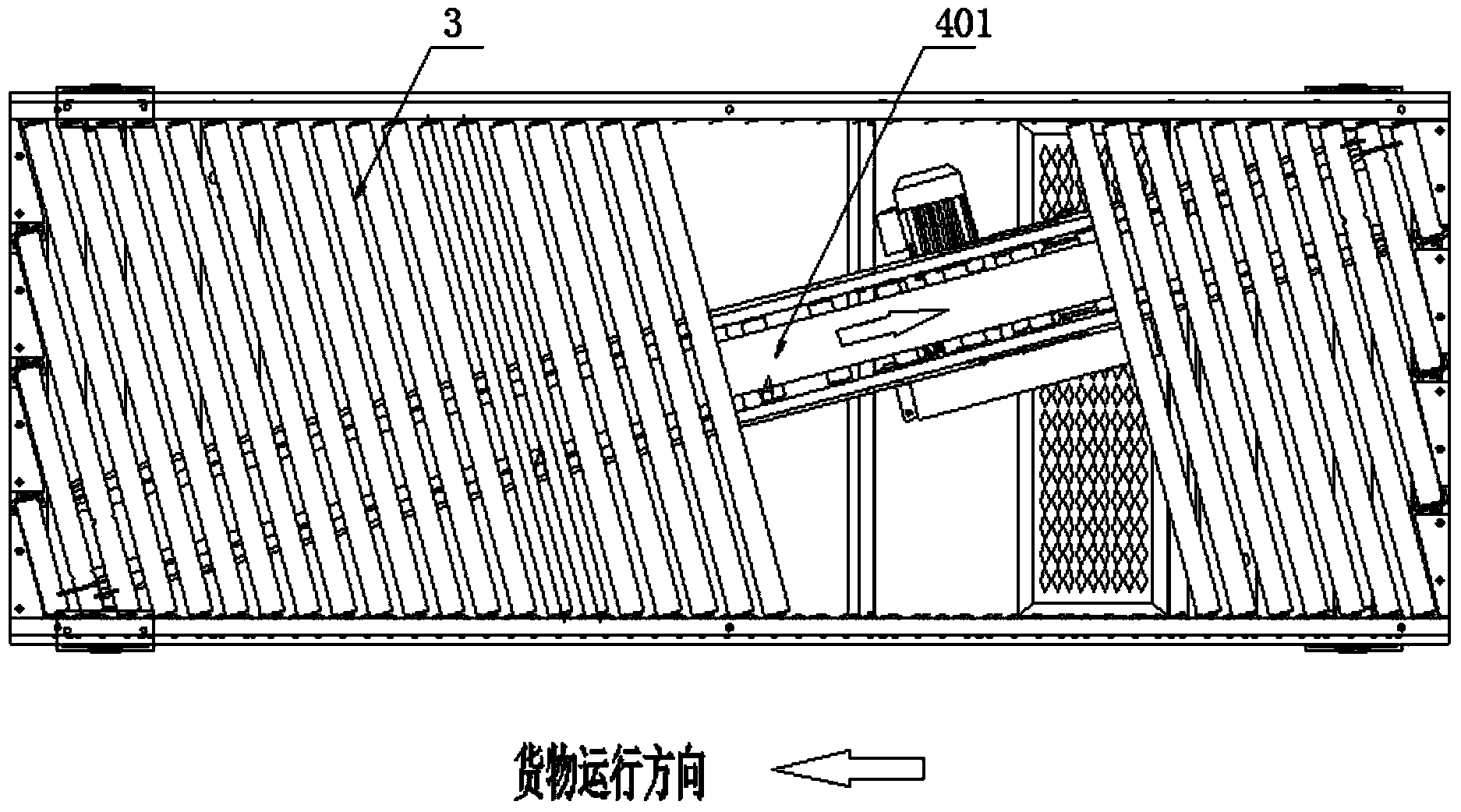

[0052] see Figure 12 , the bottom belt friction side belt conveyor is mainly composed of frame 2, side guardrail 1, side belt conveyor 7, bottom belt conveyor 4, inclined roller table 3, support connecting frame 8, side belt conveyor cover and outrigger 5, etc. composition.

[0053] see Figure 12 , through the fixed support 8 and the fixed support seat, the side belt conveyor 7 is vertically fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com