Fracturing flow-back fluid treatment device

A technology of fracturing flowback liquid and treatment device, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problem of blockage of filter bags and filter elements and poor continuous treatment capacity of equipment , many main equipments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

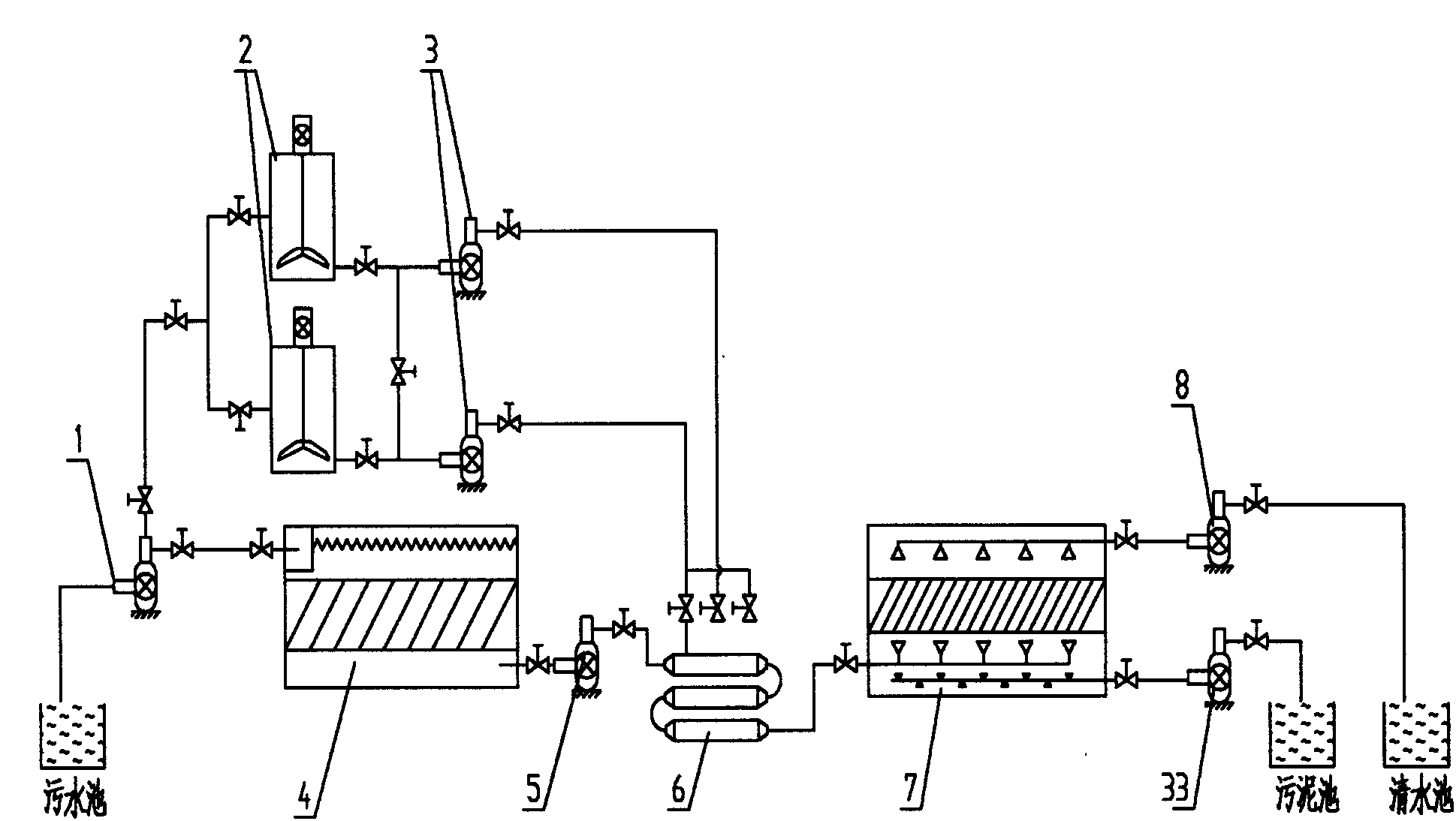

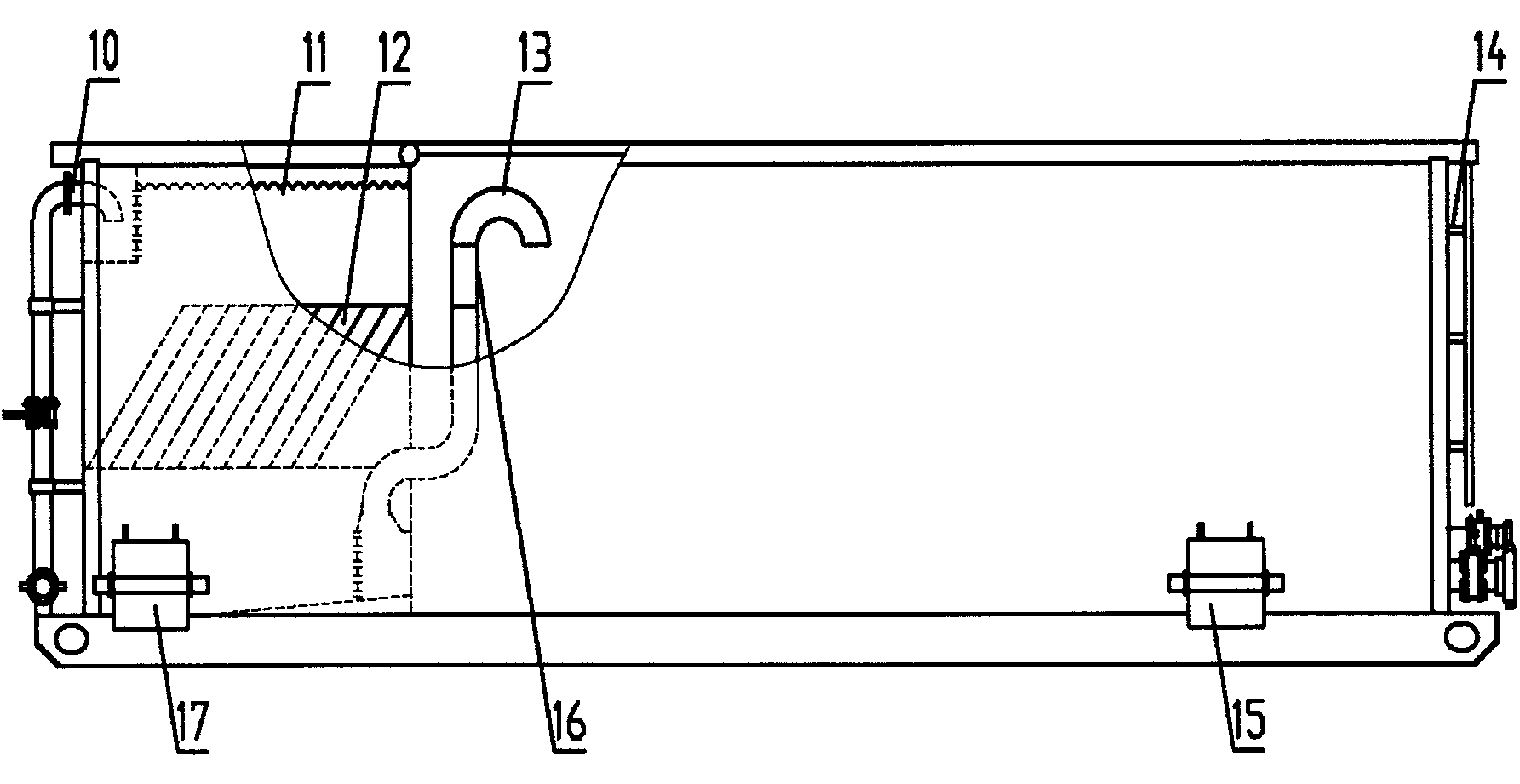

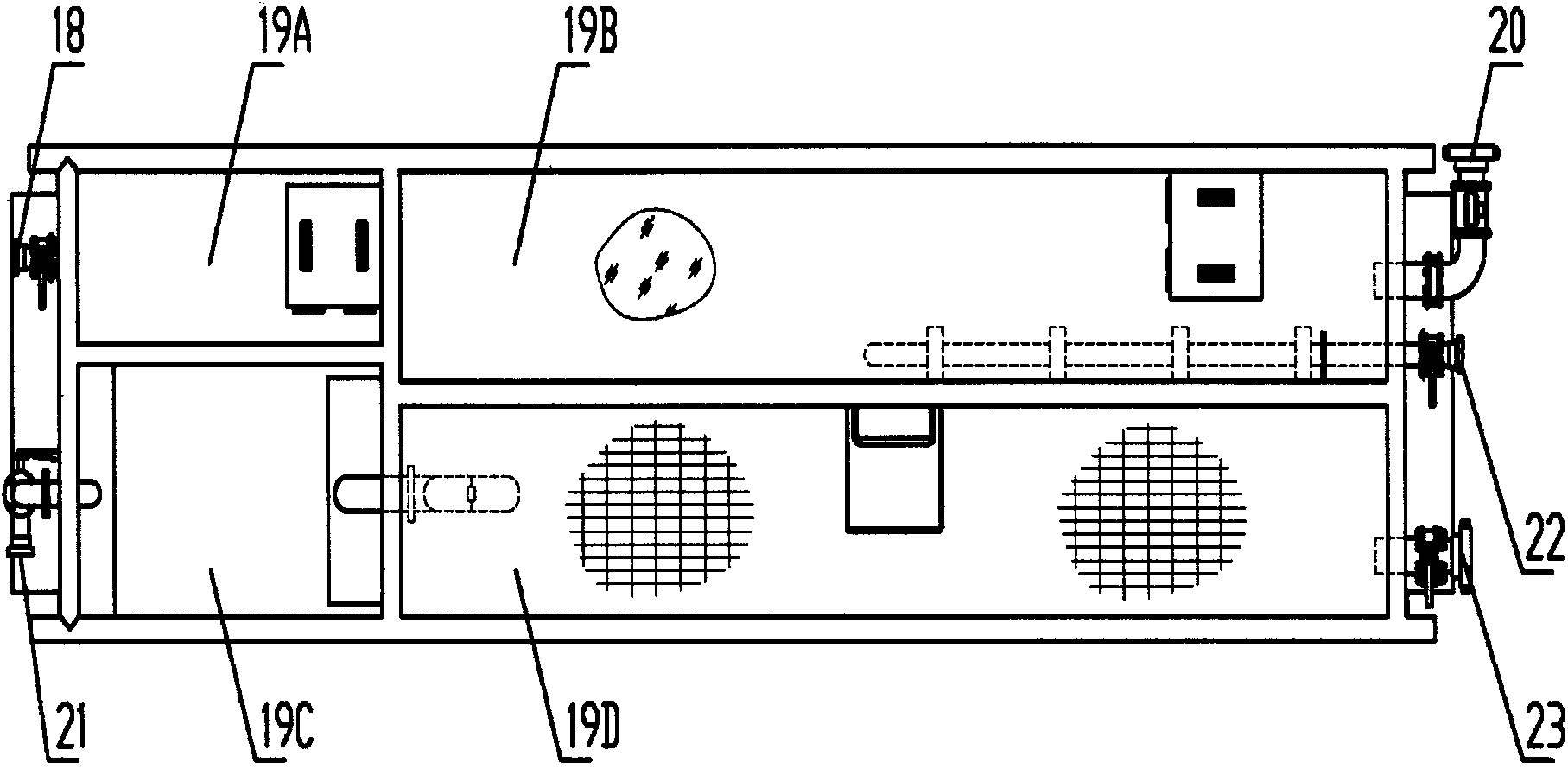

[0020] Such as Figure 1~4 As shown, the present invention includes a sewage lift pump 1, the sewage pump inlet 21 of the sewage lift pump 1 is connected with the sewage pool, and the water outlet branch of the sewage lift pump 1 is connected with the inclined tube degreasing bin inlet manifold of the inclined tube degreasing and sanding device 4 10 connected; the inclined tube degreasing and grit setting device 4 includes the inclined tube degreasing and grit chamber 19C, the dirty oil storage bin 19A, the buffer grit chamber 19D and the clean water bin 19B, and the inclined tube degreasing and grit setting device 4 is fixed on the skid as a whole Above: the inclined pipe degreasing chamber 19C and the dirty oil storage chamber 19A are separated by a toothed oil separation weir 11, and the height of the toothed oil separation weir 11 is higher than that of the inclined pipe degreasing chamber 19C. The water level of the oil tank inlet manifold 10, the bottom of the dirty oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com