A kind of vinyl ester resin and preparation method thereof

The technology of vinyl ester resin and epoxy resin, which is applied in the field of vinyl ester resin and its preparation, can solve the problems of poor thickening performance of high temperature resistant vinyl resin, reducing other properties of vinyl resin, difficult molding process and the like, Achieve the effect of improving heat resistance and corrosion resistance, superior thickening performance, and superior impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

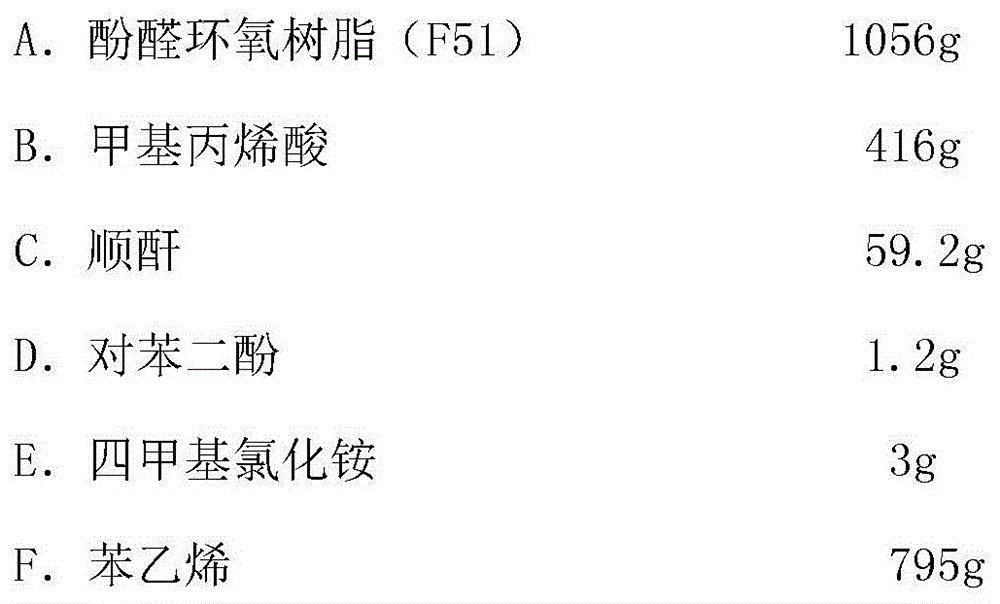

Embodiment 1)

[0019]

[0020] Put A, B, C, D, and E into the reaction kettle, react at 120°C for 2 hours, then pour into F, stir evenly, and cool to room temperature to obtain the product.

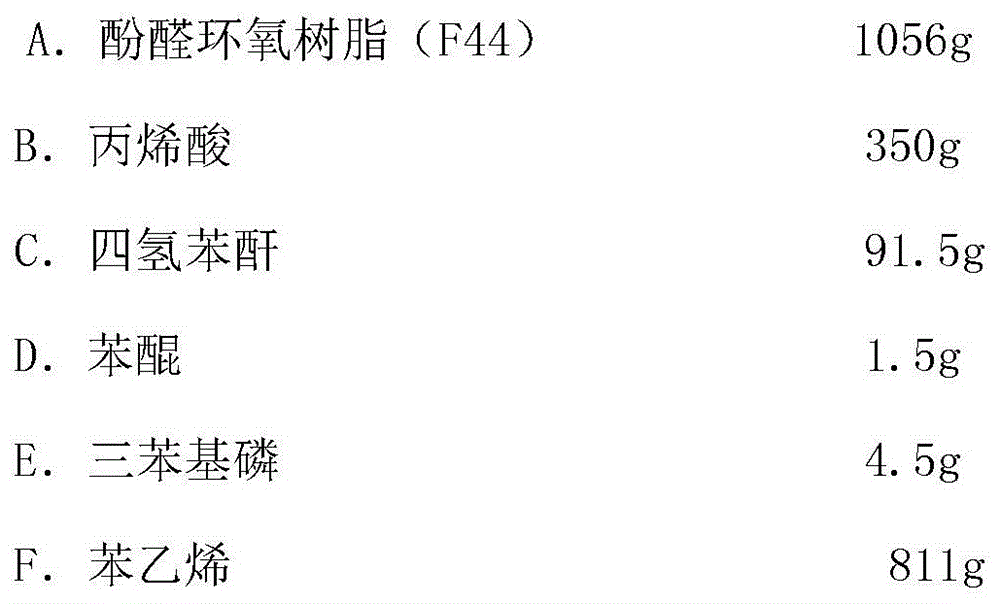

Embodiment 2)

[0022]

[0023] Put A, B, C, D, and E into the reaction kettle, react at 110°C for 4 hours, then pour into F, stir evenly, and cool to room temperature to obtain the product.

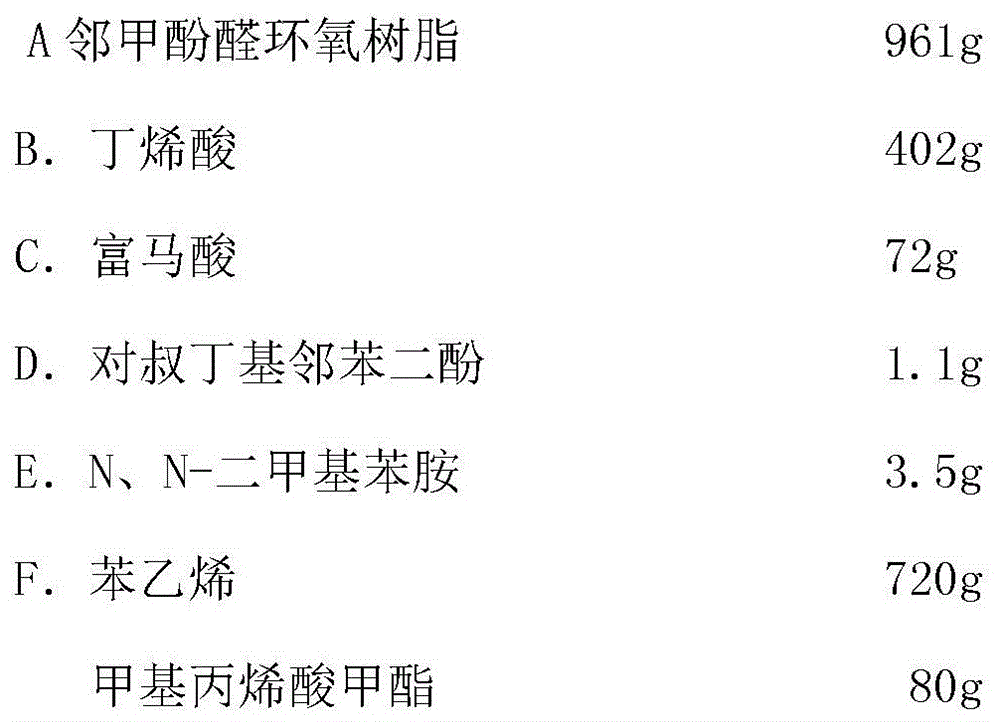

Embodiment 3)

[0025]

[0026] Put A, B, C, D, and E into the reaction kettle, react at 100°C for 6 hours, then pour into F, stir evenly, and cool to room temperature to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com