Underwater pouring type tubular column with retaining wall and construction method thereof

A construction method and pouring technology, which is applied in construction, foundation structure engineering, sheet pile walls, etc., can solve the problems of difficult splicing construction at the joints of each joint, difficult control of grouting quality, and difficult transportation of prefabricated parts. The construction period and stiffness-to-mass ratio are good, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

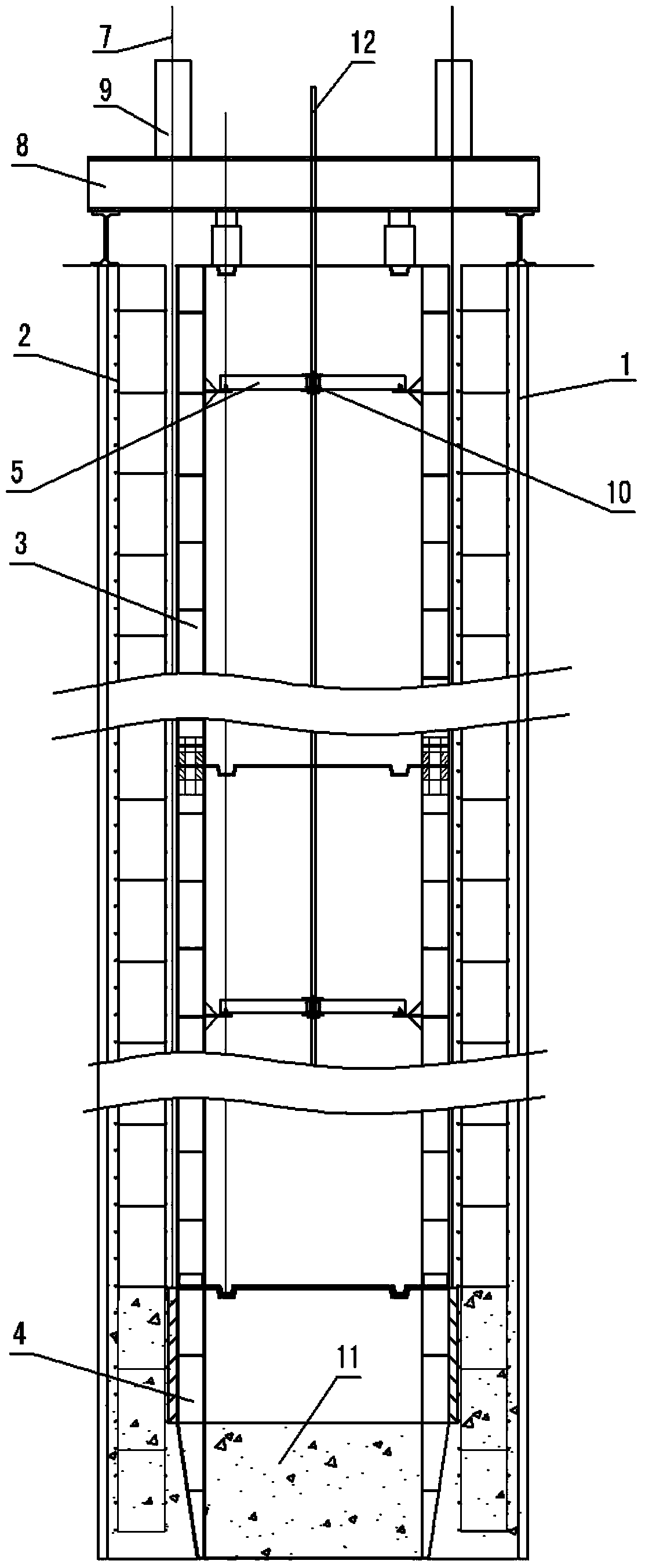

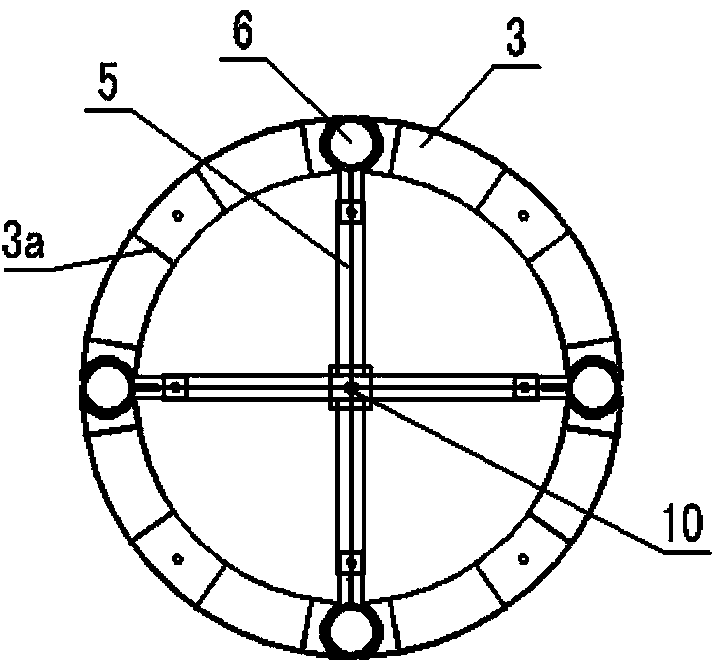

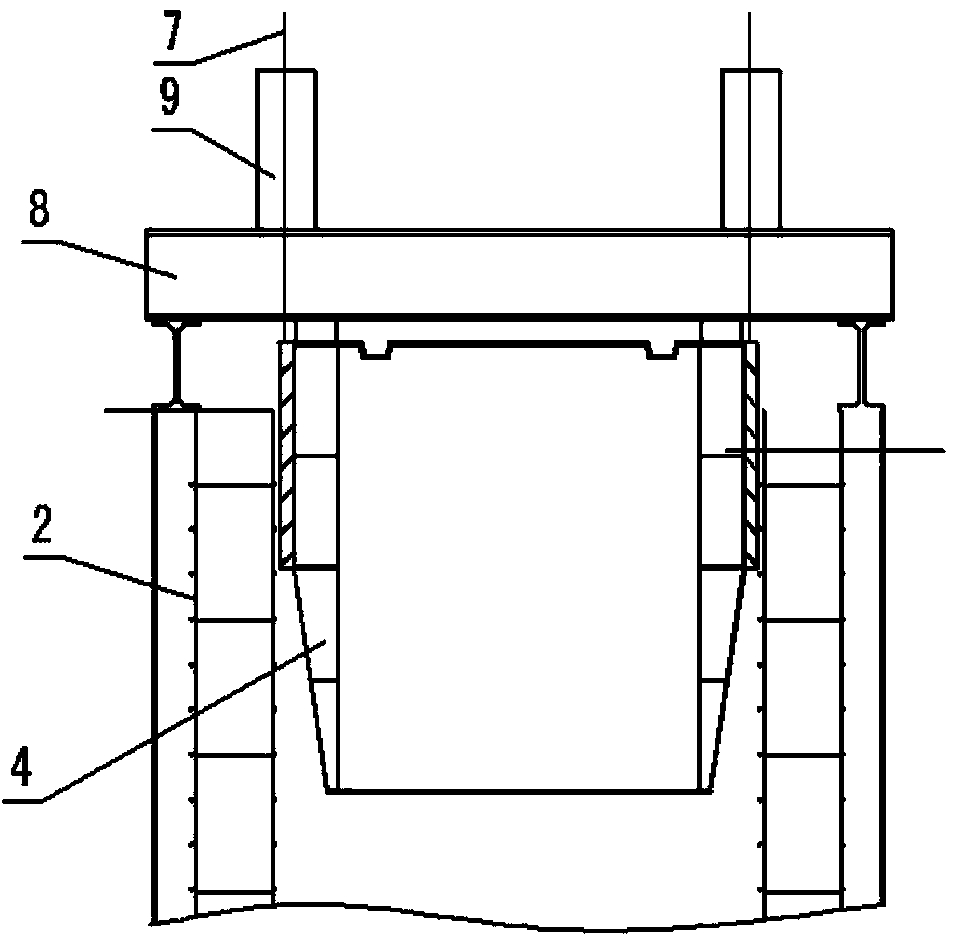

[0033] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 In this embodiment, the structural form of the internal mold system for constructing an underwater pouring pipe column with retaining walls is:

[0034] Such as figure 1 As shown, it includes a steel structure bottom section formwork 4, on the bottom section formwork 4, the prefabricated inner formwork 3 of each section is assembled section by section; the prefabricated inner formwork 3 of each section is a fully enclosed formwork that can obtain buoyancy in water Steel structure hollow buoy structure, after releasing the locking of the inner formwork, the inner formwork 3 of each segment can be recovered by floating up by buoyancy; the bottom section formwork 4 is poured in the concrete bottom cover 11 of the column hole for positioning.

[0035] Such as figure 2 and Figure 5 As shown, the prefabricated inner formwork 3 of each segment is assembled from tile templates; in the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com