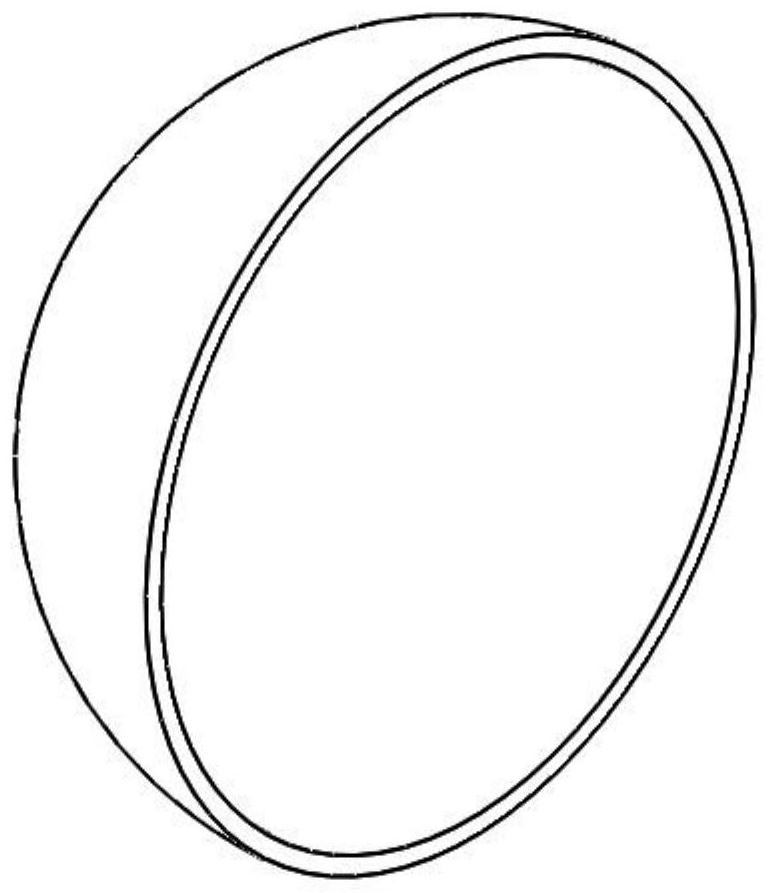

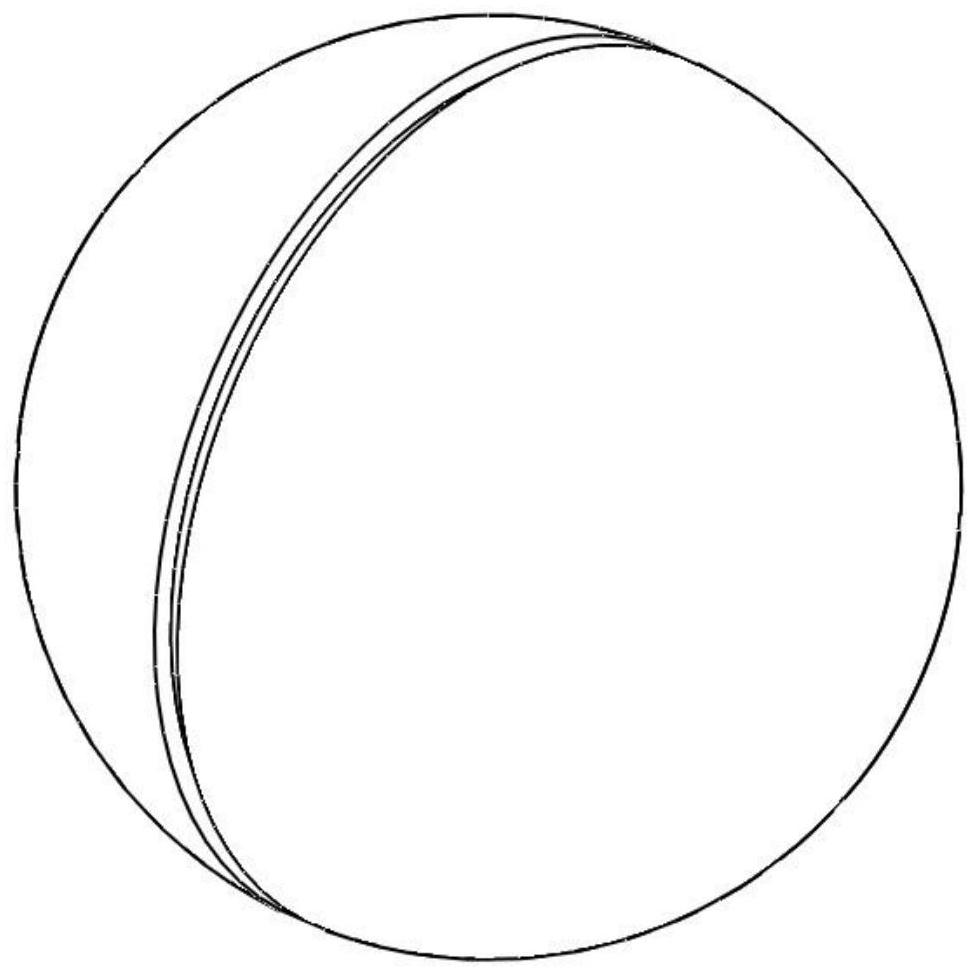

A kind of ceramic hollow buoyancy ball and its manufacturing method

A manufacturing method and technology for buoyancy balls, which are used in ceramics, buoyancy materials and marine fields, and can solve the problems of limited ball size and no ceramic hollow buoyancy balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029]Additive manufacturing technology (3D printing process) mainly has the following types: (1) (Threedimensional printing, 3DP), the "glue" type of computer-controlled nozzle is printed layer by layer on the ceramic raw material powder bed. After printing, The ceramic body is cleaned up for post-processing. (2) Stereolithography (Stereolithography, SLA or Digital Light Processing, DLP), ceramic powder is mixed in the photosensitive resin liquid, and the light source controlled by the computer is printed layer by layer on the resin bed. After the printing is completed, the green body is cleaned Come out for later processing. (3) Selective Laser Sintering (Selective Laser Sintering, SLS)

[0030] This embodiment only uses SLS 3D printing to illustrate the principle and process of forming ceramic hemispherical shell blanks. Other 3D printing processes can also form ceramic hemispherical shell blanks (the principle and process will not be described again, and this technology ...

Embodiment 2

[0037] Ceramic hemispherical shell blanks can also be formed by traditional ceramic molding techniques such as slip casting, gel injection molding, and powder pressing (cold isostatic pressing includes two processes of "wet bag" and "dry bag"). After a series of green body post-processing (such as debinding), the subsequent process is the same as the corresponding steps in Example 1.

[0038] Grouting molding refers to pouring ceramic raw material slurry in the negative spherical surface of the hemispherical plaster mold and rotating it at a certain speed. The slurry is adsorbed on the surface of the gypsum to form a hemispherical shell. After a period of time, it is solidified and formed into a hemispherical shell. The shell is taken out. After drying, debinding, sintering and other processes.

[0039] Gel injection molding is a colloidal molding process. By preparing ceramic slurry containing organic monomers, adding initiators and catalysts, injecting them into specific mol...

Embodiment 3

[0042] Ceramic hollow buoyancy balls can also be made of alumina and silicon carbide (SiC), and the ingredients are mixed uniformly by ball milling, and then spray-dried, granulated, and sieved to obtain a powder with a particle size of 15-60 μm. 3D printing or powder compression molding; it can also be prepared by ball milling method, mixed evenly and directly injected into grout, gel injection molding. The molded hemispherical shell green body undergoes a series of post-processing of the green body, and is loaded into a furnace for sintering. The subsequent processes are the same as the corresponding steps in Example 1 except for the sintering process. All those skilled in the art can realize according to the conception of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com